INSTALLATION & OPERATION MANUAL

CW-H10, CW-H15, CW-H15S, CW-H15S Plus

MULTI-MAGIC MODELS

ORIGINAL ENGLISH INSTRUCTIONS

ILL1916

CW-H INSTALLATION, OPERATION & MAINTENANCE MANUAL 859749-J | 3

TABLE OF CONTENTS

Index

IMPORTANT SAFETY INSTRUCTIONS 4

COOLER VIEWS 6

CW-H10 MODELS 6

CW-H15 MODELS 7

COOLER CONTENTS 9

INSTALLATION COMPONENTS 9

OPTIONAL COMPONENTS 9

TECHNICAL DESCRIPTION 10

AIRFLOW 10

HEAT EXCHANGERS 10

TRANSPORT 11

MOVING THE COOLER 11

LIFTING THE COOLER 11

UNPACKING THE COOLER 11

INSTALLATION 12

COOLER LOCATION 12

ACCESS FOR SERVICING AND MAINTENANCE 12

MOUNTING/SUPPORT 12

VIBRATION ISOLATION 12

DRIP-TRAY 12

SUPPLY AIR DUCT CONNECTIONS 12

EXHAUST TRANSITION ASSEMBLY 13

EXHAUST DUCT CONNECTION REQUIREMENTS 13

SUPERCOOL COOLERS 14

ELECTRICAL REQUIREMENTS 15

ELECTRICAL SUPPLY INSTALLATION 15

MOTOR LOCKED-ROTOR PROTECTION 15

HIGH LEAKAGE CURRENT 15

RESIDUAL CURRENT CIRCUIT BREAKER (RCCB) 15

FIRE TERMINALS 15

WATER REQUIREMENTS 16

WATER SUPPLY INSTALLATION 16

WATER SUPPLY PRESSURE REGULATION 16

WATER SUPPLY ISOLATION 16

WATER SUPPLY FILTRATION 16

WATER HAMMER 16

WATER DRAIN INSTALLATION 16

COOLER CONTROL COMPONENTS 17

WATER MANAGEMENT SYSTEM 17

CONTROL COMPONENTS 17

INPUT AND OUTPUT TERMINALS 17

MULTI-MAGIC CONTROLS 18

MULTI-MAGIC PLC 18

CONTROL SCREEN 18

MONITOR SCREENS 19

SENSOR SCREEN 19

CONTROL METHOD OPTION 1 (W/C) 20

SETTING DEVICE NODE ADDRESS (W/C) 20

CONTROL METHOD OPTION 2 (MBS) 21

COMMUNICATION SETUP (MBS) 21

CONTROL METHOD OPTION 3 (BCN) 22

BACNET PROTOCOL SELECTION 22

BACNET MS/TP COMMUNICATION SETUP 22

BACNET IP COMMUNICATION SETUP 22

RS-485 NETWORK SETUP 23

RS-485 CABLE SPECIFICATIONS 23

RS-485 CABLE CONNECTIONS 23

RS-485 CABLE WIRING RULES 23

RS-485 TERMINATING RESISTORS 23

RJ45 ETHERNET SETUP 23

ETHERNET CABLE SPECIFICATIONS 23

ETHERNET CABLE WIRING RULES 23

CONTROL METHOD OPTION 4 (BMS) 24

BMS FAULT OUTPUT 24

BMS CONTROL INPUTS 24

BMS FAN SPEED INPUT 24

BMS CABLING REQUIREMENTS 24

CONTROL METHOD OPTION 5 (LCL) 25

MANUAL DRAIN 25

CHANGING COOLER SETTINGS 26

PRE-WET 26

FAN START DELAY & RUN OUTPUT RELAY 26

BMS LOCK SPEED 27

MESSAGE BAR CONTENTS 27

LED STATES 28

FAULT CODE DISPLAY 28

FAULT CODE RESET 28

FAULT CODE DESCRIPTIONS 29

COMMISSIONING 30

INSTALLATION CHECKLIST 30

SETUP MENU ACCESS 31

MULTI-MAGIC DEVICE TYPE 31

TEST MENU 31

WATER MANAGEMENT SYSTEM CHECKS 31

HEAT EXCHANGER FLUSH 31

SUPPLY FAN CHECKS 31

AIR FLOW BALANCING 32

MULTI-MAGIC COOLER SETTINGS 33

MULTI-MAGIC RS-485 SETTINGS 33

MULTI-MAGIC IP SETTINGS 33

CUSTOMER HANDOVER CHECKLIST 33

MAINTENANCE SCHEDULE 34

MAINTENANCE FREQUENCY 34

WINTER SHUTDOWN 34

MAINTENANCE CHECKLIST 35

MAINTENANCE INSTRUCTIONS 37

COOLER CONTROL 37

QUARTERLY INSPECTION PROCEDURES 37

INDIRECT & DIRECT PUMPS 38

WATER INLET SOLENOID VALVE 38

CHLORINATOR 39

WATER MANAGEMENT PROBE 39

WATER RESERVOIR (TANK) 39

DRAIN VALVE 40

INLET AIR FILTERS 40

INDIRECT HEAT EXCHANGERS 41

DIRECT HEAT EXCHANGERS (CHILLCEL) 42

TROUBLESHOOTING 43

WARRANTY TERMS (AUSTRALIA) 44

WARRANTY TERMS (USA) 48

APPENDIX A 52

EXAMPLE WALL CONTROLLER WIRING 52

APPENDIX B 54

EXAMPLE LOW VOLTAGE BMS WIRING 54

APPENDIX C 55

MODBUS REGISTERS 55

APPENDIX D 56

BACNET OBJECT LIST 56

4 | CW-H INSTALLATION, OPERATION & MAINTENANCE MANUAL 859749-J

IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS

FOR FUTURE REFERENCE.

FOR EUROPE

This appliance can be used by children aged

from 8 years and above and persons with

reduced physical, sensory or mental capabilities

or lack of experience and knowledge if they

have been given supervision or instruction

concerning use of the appliance in a safe way

and understand the hazards involved. Children

shall not play with the appliance. Cleaning and

user maintenance shall not be made by children

without supervision.

FOR AUSTRALIA, NEW ZEALAND & OTHER

NON-EUROPEAN COUNTRIES

This appliance is not intended for use by

persons (including children) with reduced

physical, sensory or mental capabilities, or

lack of experience and knowledge, unless they

have been given supervision or instruction

concerning use of the appliance by a person

responsible for their safety. Children should be

supervised to ensure that they do not play with

the appliance.

Means for all pole disconnection must be

incorporated in the xed wiring in accordance

with the wiring rules, adjacent to or on the

cooler cabinet. If mounting on the cooler

cabinet, take care not to puncture the water

reservoir.

The following specications for the cooler water

supply are required:

Water Connection ½” BSP (Aus/Eur), ½” NPT

(USA)

Min Water Pressure 100kPa (15psi)

Max Water Pressure 800kPa (115psi)

Max Water Flow 20 L/min (5.3 gallons/min)

Max Water Temperature 40°C (104°F)

This cooler is intended to be permanently

connected to the water mains and not

connected by a hose set.

If the supply cord is damaged, it must be

replaced by the manufacturer, its service agent

or similarly qualied persons in order to avoid a

hazard.

CAUTION: In order to avoid a hazard due to

inadvertent resetting of the thermal cut-out,

this appliance must not be supplied through an

external switching device, such as a timer, or

connected to a circuit that is regularly switched

on and o by the utility.

FOR AUSTRALIAN BUSHFIRE PRONE

AREAS

WARNING If this evaporative cooler is installed

in a BAL-12.5 to 29 area the evaporative cooler

dropper duct and ashings shall be adequately

sealed at the roof to prevent gaps greater than

3mm. The dropper duct and ashings shall be

non-combustible.

WARNING: This cooler is NOT APPROVED

for installation in any bushre zoned area/

property (BAL-12.5 to BAL-FZ).

WARNING - TO REDUCE THE RISK OF

FIRE, ELECTRIC SHOCK, OR INJURY TO

PERSONS, OBSERVE THE FOLLOWING:

a) Use this unit only in the manner intended

by the manufacturer. If you have questions,

contact the manufacturer.

b) Before servicing or cleaning unit, switch

power o at service panel and lock the

service disconnecting means to prevent

power from being switched on accidentally.

When the service disconnecting means

cannot be locked, securely fasten a

prominent warning device, such as a tag, to

the service panel.

c) Installation work and electrical wiring

must be done by qualied person(s) in

accordance with all applicable codes and

standards, including re-rated construction.

d) When cutting or drilling into wall or ceiling,

do not damage electrical wiring and other

hidden utilities.

e) Do not use this fan with any solid-state

speed control device.

f) Ducted fans must always be vented to the

outdoors.

EMPLOYER AND EMPLOYEE

RESPONSIBILITIES

The installation and maintenance of evaporative

coolers at height has the potential to create

Occupational Health and Safety issues for

those involved. Installers are advised to ensure

they are familiar with the relevant State and

Federal legislation, such as Acts, Regulations,

approved Codes of Practice and Australian

Standards, which oer practical guidance on

these health and safety issues. Compliance

with these regulations will require appropriate

work practices, equipment, training and

qualications of workers.

Seeley International provides the following

information as a guide to contractors and

employees to assist in minimising risk whilst

working at height.

CW-H INSTALLATION, OPERATION & MAINTENANCE MANUAL 859749-J | 5

As with any product that has moving parts

or is subject to wear and tear, it is VERY

IMPORTANT that you maintain your cooler

and have it regularly serviced. It is a condition

of warranty cover for your cooler that you

comply with all of the maintenance and

service requirements set out in this Manual.

Compliance with these requirements will

prolong the life of your cooler. Further, it is also

a condition of warranty cover that each item

in the Maintenance Schedule in the Manual is

lled out (by signing and dating it in the places

indicated) when the item is completed.

Any failure to carry out the required

maintenance and servicing, and any failure to

ll out the maintenance schedule, will void your

warranty.

MAINTENANCE NOTE

IMPORTANT SAFETY INSTRUCTIONS

INSTALLER AND MAINTENANCE

CONTRACTORS - RISK ASSESSMENT

Installer and Maintenance Contractors

A risk assessment of all hazardous tasks is

required under legislation. A risk assessment is

an essential element that should be conducted

before the commencement of work, to identify

and eliminate the risk of falls or to minimise

these risks by implementing control measures.

There is no need for this to be a complicated

process, it just is a matter of looking at the job

to be done and considering what action(s) are

necessary so the person doing the job does not

injure themselves.

This should be considered in terms of:

• What are the chances of an incident

happening?

• What could the possible consequence be?

• What can you do to reduce, or better still,

completely get rid of the risk?

SOME POINTS TO CONSIDER

• What is the best and safest access to the

roof and working areas?

• If a worker is alone, who knows they are

there and if they get into diculty, how can

they summon help?

• (Call someone on the ground? Mobile

phone? etc.)

• What condition is the roof in? Should the

trusses, underside or surface be checked?

• Does the worker have appropriate foot

wear? (Flat sole jogger type is advisable)

• Are all power cables / extension leads safe

and appropriately rated?

• Are all ladders, tools and equipment suitable

in good condition?

• Where ladders are to be used, is there a

rm, stable base for them to stand on?

Can they be tied or secured in some way

at the top? Is the top of the ladder clear of

electricity supply cables?

• Is there a roof anchor to attach a harness

and lanyard to? If so, instruction should be

issued for the use of an approved harness

or only suitably trained people used.

• Are all tools and materials being used,

prevented from slipping and falling onto a

person at ground level? Is the area below

the work area suitably protected to prevent

persons walking in this area?

• Does the work schedule take into account

weather conditions, allowing for work to be

suspended in high winds, thunder storms/

lightning or other types of weather giving

wet, slippery surfaces?

• Is there an on-going safety check system of

harnesses, ropes, ladders and access/lifting

equipment and where they exist on roofs,

anchor points before the commencement of

work?

• Is there a system which prevents employees

from working on roofs if they are unwell or

under the inuence of drugs or alcohol?

• Are there any special conditions to consider

i.e. excessive roof pitch, limited ground

area, fragile roof, electrical power lines?

OTHER IMPORTANT REQUIREMENTS

• Never force parts to t because all parts are

designed to t together easily without undue

force.

• Never drill holes in the tank of the cooler.

• Check the proposed cooler location, to

ensure that it is structurally capable of

supporting the weight of the cooler, or

provide an adequate alternate load bearing

structure.

• Ensure the installation complies with all

local and national regulations with regards

to electrical, plumbing and bushre

construction requirements.

6 | CW-H INSTALLATION, OPERATION & MAINTENANCE MANUAL 859749-J

COOLER VIEWS

Dimensions are in mm (inches in brackets).

CW-H10 MODELS TOP

REAR SIDE

BOTTOM

ILL3156-A

ILL3157-A

ILL3158-A

ILL3159-A

ILL3161-A

FRONT

ILL3160-A

CW-H INSTALLATION, OPERATION & MAINTENANCE MANUAL 859749-J | 7

COOLER VIEWS

ILL1916

2290

[90.2]

1969

[77.5]

1825

[71.9]

1500

[59.1]

ILL1918

CW-H15 MODELS

TOP

REAR SIDE

BOTTOM

ILL1916-C

ILL1918-C

ILL1917-C

ILL1919-C

ILL1920-C

482

[19.0]

150

[5.9]

SUPPLY DUCT

500x500

(19.7x19.7)

668

[26.3]

419

[16.5]

509

[20.0]

1300

[51.2]

481

[18.9]

650 [25.6]

ILL1919

MOUNTING BASE

EXHAUST DUCT

1822 [71.7]

EXHAUST DUCT

217 [8.6]

1283

[50.5]

EXHAUST C/L

1171

[46.1]

MOUNTING BASE

1800 [70.9]

ILL2422

FRONT

ILL2422-C

50

[2.0]

400

[15.7]

800

[31.5]

1200

[47.2]

50

[2.0]

550

[21.7]

1150

[45.3]

1700

[66.9]

MOUNTING HOLES

10

[0.394]

TYP 16 PL

ILL1920

BASE FRAME UNDERSIDE

Dimensions are in mm (inches in brackets).

8 | CW-H INSTALLATION, OPERATION & MAINTENANCE MANUAL 859749-J

COOLER VIEWS

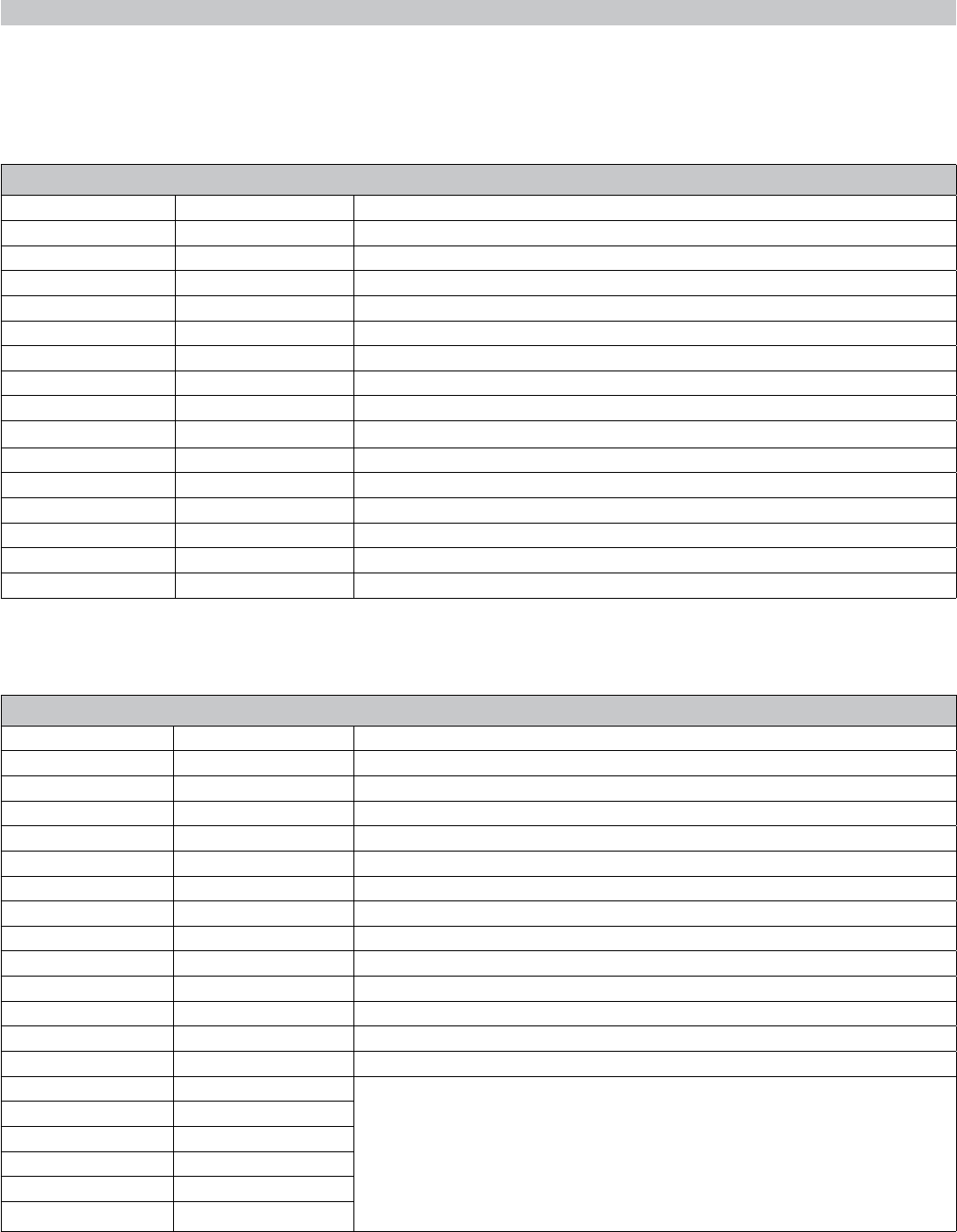

ILL2423-D

Item Description

1 AIR FILTER ASSEMBLY

2 ELECTRICAL ENCLOSURE

3 FAN GUARD

4 END PANELS

5 MOTOR AND FAN ASSEMBLY

6 INLET TRANSITION ASSEMBLY

7 PUMPS, DRAIN VALVE AND WATER PROBE

8 PUMPS, INLET SOLENOID VALVE AND CHLORINATOR

9 WATER TANK

10 BASE FRAME

11 SIDE PANELS AND ACCESS DOORS

12 OUTLET TRANSITION ASSEMBLY

13 SUPPLY DAMPER

14 INDIRECT HEAT EXCHANGER AND WATER SPREADERS

15 EXHAUST AIR GRILLE

16 LID ASSEMBLY

1

3

2

4

4

5

9

7

8

10

6

11

11

12

13

14

15

16

CW-H INSTALLATION, OPERATION & MAINTENANCE MANUAL 859749-J | 9

COOLER CONTENTS

INSTALLATION COMPONENTS

OPTIONAL COMPONENTS

Item

Seeley

Part

Description QTY

1A

1B

859749

862801

Cooler Installation, Operation, Maintenance Manual

Supercool Conversion Instructions (CW-H15S only)

1

2 861883 Adaptor Drain Elbow 1

3 866216 40mm Flexible Coupling 1

4 834798 Key, Control Box 1

5A

5B

637994

637393

Exhaust Centre Post CW-H15 or

Exhaust Centre Post CW-H10

1

6A

6B

6C

6D

6E

6F

6G

805597

804446

804422

864341

864385

864372

804579

Screw 8AB x ½” Pan Phill Stainless Steel

Screw SEMS HX 14x3/4"

Plastic Grommet Size 14

Screw Set SHCS Stainless Steel M6x35mm

Washer Flat Stainless Steel M6x12.5x1.2mm

Washer Flat Nylon M8x16mm

Blanking Grommet 12.7x17.5mm

10

5

5

4

4

4

2

7 931685 Exhaust Side Rails (1176mm Long) 2

8A

8B

834789

834790

Exhaust Grille (869x205) CW-H15 or

Exhaust Grille (571x247) CW-H10

1

9 637999 Exhaust Cap (CW-H15S Plus only) 2

Item

Seeley

Part

Description

1 121956 Multi-Magic Wall Control Kit

2A

2B

134192

134215

Roofstand 0-10

O

(CW-H10)

Roofstand 0-10

O

(CW-H15, H15S, H15S Plus)

3 121963 Multi-Magic Room Air Sensor Kit

4 121932 Multi-Magic Ambient Air Sensor Kit

5 121925 Multi-Magic Duct Air Sensor Kit

6 121918 Multi-Magic Pressure Sensor Kit

ITEM 7

ITEM 8A/8B

ITEM 9

ITEM 10

ITEM 1

ITEM 2

ITEM 3A

ITEM 4

ITEM 3B

WARRANTY INFORMATION

DUCTED INDIRECT EVAPORATIVE

AIR COOLER

INTERNATIONAL

ILL2424-D

ITEMS &5A 5B

ITEMS A, B &D66 6

ITEMS E &F66

ITEM 7

ITEM 8A/8B

ITEM 9

ITEM 10

ITEM 1

ITEM 2

ITEM 3A

ITEM 4

ITEM 3B

WARRANTY INFORMATION

DUCTED INDIRECT EVAPORATIVE

AIR COOLER

INTERNATIONAL

ILL2424-D

ITEMS &5A 5B

ITEMS A, B &D66 6

ITEMS E &F66

ITEM 1A ITEM 2 ITEM 3

ITEM 7

ITEM 8A/8B

ITEM 9

ITEM 10

ITEM 1

ITEM 2

ITEM 3A

ITEM 4

ITEM 3B

WARRANTY INFORMATION

DUCTED INDIRECT EVAPORATIVE

AIR COOLER

INTERNATIONAL

ILL2424-D

ITEMS &5A 5B

ITEMS A, B &D66 6

ITEMS E &F66

ITEM 4 ITEM 5 ITEM 6A ITEM 6B ITEM 6C

ITEM 6D ITEM 6E/F ITEM 6G

ITEM 7 ITEM 8

ITEM 9

ITEM 1B

ILL2426-A

ILL3803-A

ILL3709-A

ILL3709-A

ITEM 1

ITEM 3

ITEM 4 ITEM 5

ILL3867-A

ILL3962

ITEM 6

ITEM 2

10 | CW-H INSTALLATION, OPERATION & MAINTENANCE MANUAL 859749-J

TECHNICAL DESCRIPTION

AIRFLOW

The cooler has a single fan which draws hot outside air through

the rear-mounted air lters, through the dry channels of the air-

to-air indirect evaporative heat exchangers and into the plenum

at the front of the cooler.

Inside the plenum, the air is split into an exhaust ow and a

supply ow.

The exhaust air passes through the wet channels of the air-to-

air indirect evaporative heat exchangers and out through the

upper exhaust grille back to atmosphere.

The supply air passes over a secondary direct evaporative

cooling stage (Supercool cooler only), before entering the

customer's ductwork.

HEAT EXCHANGERS

Indirect Evaporative Cooling (IEC) Stage

All coolers have air-to-air indirect evaporative heat exchangers,

composed of alternating dry and wet channels separated by a

membrane. CW-H10 has 2 and CW-H15 has 3.

Through evaporation and conduction, heat is transferred from

the air in the dry channels, across the membrane, and into the

air in the wet channels.

The air in the dry channels is progressively cooled, but gains no

additional moisture.

Direct Evaporative Cooling (DEC) Stage

Supercool coolers are tted with a secondary direct evaporative

cooling stage.

The cooled air from the IEC stage passes over saturated

Chillcel® media, where, through evaporation, it is cooled further

with an increase in moisture content.

FAN

DEC STAGE

(SUPERCOOL

COOLERS)

IEC STAGE

SUPPLY AIR

EXHAUST AIR

FILTERS

INTAKE AIR

ILL3883

CW-H INSTALLATION, OPERATION & MAINTENANCE MANUAL 859749-J | 11

ILL1916

TRANSPORT

UNPACKING THE COOLER

The cooler will be delivered on a dedicated pallet and will be

wrapped in plastic lm which will need to be removed before

installation.

A small bag of installation components along with the exhaust

transition side rails and grilles can be found under the lid of the

main cabinet of the cooler. The exhaust transition will need to

be raised into place before operation.

WARNING: Once unwrapped, the exhaust transition assembly

should be tted together as soon as practicable to avoid loose

components becoming lost/damaged and/or a hazard.

MOVING THE COOLER

The cooler can be moved by forklift truck. Only use the

openings on the cooler. Do not lift through the pallet.

ILL1916-A

Min. forklift tyne gap

460mm (18.2”)

LIFTING THE COOLER

The cooler may be lifted by crane with slings through the cooler

base forklift truck tyne openings.

Do not attempt to lift using any cabinet features or by retrotting

lifting lugs. The cabinet may be damaged and/or lift safety

compromised.

It is recommended to use a spreader bar on the straps or slings

to protect the upper edges of the cooler with a corner protector

beneath the lifting straps to avoid any damage to the cabinet

during the lift.

12 | CW-H INSTALLATION, OPERATION & MAINTENANCE MANUAL 859749-J

The cooler base has a series of mounting holes for securing

the cooler. Dimensions and locations of the mounting holes are

shown in the cooler views at the beginning of this manual.

Where necessary, installers should use a sucient number of

suitably rated vibration isolation mounts to support the operating

mass of the cooler.

DRIP-TRAY

When coolers are installed indoors, or anywhere that water

leakage could cause damage, install a corrosion resistant drip

tray under the whole unit.

Recommended sizes:

CW-H10:

1500 x 1300 x 50mm (59” x 51” x 2”)

CW-H15, H15S, H15S PLUS:

1500 x 1900 x 50mm (59” x 75” x 2”)

Apply silicone sealant between drip-tray and cooler base at

every xing.

SUPPLY AIR DUCT CONNECTIONS

Dimensions for the supply air duct interface are shown in the

cooler views at the beginning of this manual.

Vibration absorbing exible connections are recommended for

all duct connections to the cooler.

All ducts must be independently supported.

All duct direction changes must utilise a generous radial turn

with internal air directors to minimise turbulence and maximise

eciency.

All ducts are to be suitably insulated to minimise temperature

losses.

INSTALLATION

MOUNTING/SUPPORT

Roofstands, accommodating 0-10 roof pitches, are available for

order via Seeley International. See Optional Components List.

ILL2426-A

ILL2426-A

COOLER LOCATION

Check the proposed cooler location, to ensure that it is

structurally capable of supporting the weight of the cooler, or

provide an adequate alternate load bearing structure.

Model Shipping Weight Operating Weight

CW-H10 250KG (550 LB) 255KG (560 LB)

CW-H15 340KG (750 LB) 330KG (728 LB)

CW-H15S, H15S Plus 355KG (783 LB) 345KG (761 LB)

Always locate the cooler where it will receive a plentiful supply

of fresh air, NOT in a recess where it may be starved for air or

where the air is polluted. Provision must be made for access to

electricity, water supplies and drains.

Air exiting the cooler exhaust is warm and heavily laden

with moisture. Ensure the cooler’s exhaust air will not cause

corrosion or damage to other nearby items. Do not allow

exhaust air to re-circulate into the air intake of the cooler.

Ensure the cooler location is a minimum of:

• 3.0m (10’) from a solid fuel heater ue

• 1.5m (5’) from a gas ue

• 1.0m (3.5’) away from adjacent solar panels or similar roof

mounted xtures

• 6.0m (20’) from a sewer vent

• 3.0m (10’) (preferably 5.0m (17’)) away from any TV antenna

or antenna cables. Make sure the cooler is not between the

antenna and the transmission tower that is providing the

television signal to the home.

ILL1925-A

Extra service or warranty charges may apply for the cost of any

equipment or additional labour involved in accessing the cooler

if these guidelines are not met.

Note! Do you need to discuss the installation of items like

safety anchor points with the customer?

ACCESS FOR SERVICING AND

MAINTENANCE

The cooler should be installed in a position that allows adequate

access for installation, and future maintenance and servicing

activities. This should comply with installation guidelines and

any local, State and National regulations.

Consider the following for installation location:-

• Which has clear access to and around the cooler

• Which is clear of xtures in line with below clearances

• Which is clear of fall edges (> 3m (10') away)

• Which is structurally capable of supporting the weight of the

cooler and service technicians

Required clearances around the cooler for future maintenance

and servicing are shown below.

CW-H INSTALLATION, OPERATION & MAINTENANCE MANUAL 859749-J | 13

EXHAUST TRANSITION ASSEMBLY

The exhaust transition is supplied in knock-down form and it's

components are to be found beneath the lid of the cooler and

inside the component kit.

1. Unscrew the 6 x SCREW SEMS HEX 14 x 3/4” securing

the large top panel to the cooler body.

ILL2427-A

ILL2427-A

4. Fit the supplied 3 x PLASTIC GROMMET SIZE 14 to the

rear lid panel upstand square holes.

ILL2428-A

ILL2428-A

5. Fit the supplied 2 x PLASTIC GROMMET SIZE 14 to the

EXHAUST CENTRE POST.

ILL2429-A

ILL2429-A

6. Position the large top panel over the top of the cooler, with

the rear u-channel over the top of the upstand, the side

rails sitting on the tops of the cooler side walls and the

end posts sitting on the outside of the front tray.

ILL2430-A

ILL2428-A

7. Slip the 2 x EXHAUST GRILLE and 1 x EXHAUST

CENTRE POST into position, retained inside the top panel

front u-channel.

CW-H15S Plus ONLY: Before tting to the cooler, slide an

EXHAUST CAP over the back of each EXHAUST GRILLE.

The EXHAUST CAP covers the top portion of the EXHAUST

GRILLE, and is designed to optimise the CW-H15S Plus

performance.

ILL2431-A

8. Screw the exhaust transition assembly to the cooler body

with the supplied 11 x SCREW SEMS HEX 14 x 3/4” .

(

3 x Rear, 3 x Left, 3 x Right, 2 x Centre Post.)

9. Fit the supplied 4 x M6 x 35MM SET SCREW,

STAINLESS STEEL FLAT WASHER, NYLON FLAT

WASHER to the tops of both core access doors (2 each

side). Apply a liberal coat of anti-seize paste to the screw

thread prior to tment.

10. Fit the supplied 2x BLANKING GROMMETS to the open

holes in the lid sides (1 each side).

ILL2432-B

INSTALLATION

EXHAUST DUCT REQUIREMENTS

If required for indoor installations the exhaust air may be ducted

away from the cooler.

Dimensions for the exhaust outlet are shown in the cooler views

at the beginning of this manual.

When designing the exhaust duct please note the following;

• Access to the heat exchanger cores requires the removal of

the cooler lid/exhaust transition. Ensure any additional ducting

is readily removable and/or lightweight.

• Where an installation requires extended exhaust ducts, the

increase in static load should not exceed 20 Pa (0.08 in wg).

2. Lift the large top panel and locate;

• 2 x EXHAUST SIDE RAILS (1176mm Long)

• 2 x EXHAUST GRILLE

• 2 x EXHAUST CAPS (CW-H15S Plus Only)

3. Fit the EXHAUST SIDE RAILS to the inside vertical faces

of the large top panel with the supplied 10 x SCREW

PAN PHILLIPS 8AB*1/2” SS. Ensure the foam seal faces

down.

M6 x 35MM

DOOR SCREWS

& WASHERS

BLANKING

GROMMET

14 x 3/4"

BODY SCREWS

14 | CW-H INSTALLATION, OPERATION & MAINTENANCE MANUAL 859749-J

INSTALLATION

The CW-H Supercool coolers are tted with Chillcel pads,

providing additional Direct Evaporative Cooling (DEC).

They can be congured in two ways;

ILL3663-A

ILL3665-A

ILL2431-A

STEP 1 - EXHAUST CAPS

MODEL PERFORMANCE

Supply Airow

Rate

External Static

Pressure

CW-H15S 1100 L/s 120 Pa

3960 m3/h

2330 CFM 0.52 in.w.g.

CW-H15S Plus 1600 L/s 80 Pa

5760 m3/h

3390 CFM 0.32 in.w.g.

To correctly congure this cooler, ensure the following steps are

followed during the installation and commissioning process;

MODEL FIT EXHAUST CAPS?

CW-H15S NO

CW-H15S Plus YES

This CW-H cooler has been supplied with 2x Exhaust Caps

(P/N 637999), shipped loose under other exhaust components.

For CW-H15S PLUS ONLY slide an EXHAUST CAP over the

back of each EXHAUST GRILLE. The EXHAUST CAP covers

the top portion of the EXHAUST GRILLE and is designed to

optimise the CW-H15S PLUS performance.

FIT EXHAUST CAPS TO BACK OF EXHAUST GRILLE

STEP 2 - SET CORRECT DEVICE TYPE

MODEL CHANGE DEVICE TYPE?

CW-H15S YES

CW-H15S Plus NO - FACTORY DEFAULT

SETTING IS CORRECT

For CW-H15S ONLY access the SETUP menu on the PLC to

change DEVICE TYPE.

ILL3664-A

Push and hold the RIGHT

button until the password

screen is displayed.

Use the navigation LEFT/

RIGHT and UP/DOWN buttons

to enter password “7378” and

push OK to display the SETUP

screen.

Use the navigation UP/DOWN

buttons to move the cursor to

DEVICE TYPE and push OK

Push OK to activate the

MODEL eld.

Use the navigation UP/DOWN

buttons to select CW-H15S.

Push OK to save the setting.

Push and hold the LEFT

button to return to the previous

menu. Repeat until the display

returns to the “CONTROL”

menu.

All CW-H coolers require the supply air plenum pressure to

be correctly set. Follow the detailed instructions set out in the

Commissioning section of this manual.

STEP 3 - SET SUPPLY AIR PLENUM PRESSURE

MODEL PLENUM PRESSURE

CW-H15S 175 Pa (0.70 in.w.g.)

CW-H15S Plus 210 Pa (0.84 in.w.g.)

ILL3665-A

LOGIN

Enter Password

7378

7378

ILL3664-A

ILL3666-C

ILL3667-B

ILL3666-C

SETUP

DEVICE TYPE

COMMUNICATION

SERVICE

SETTINGS

ILL3667-B

DEVICE TYPE

PRODUCT

FAMILY

MODEL

VOLTAGE

CW-H

380-480V/3PH

CW-H15S

ILL3668-A

ILL3668-A

SUPERCOOL COOLERS

CW-H INSTALLATION, OPERATION & MAINTENANCE MANUAL 859749-J | 15

ELECTRICAL REQUIREMENTS

ELECTRICAL SUPPLY INSTALLATION

INSTALLATION OF THE COOLER MUST CONFORM

TO LOCAL ELECTRICAL RULES, REGULATIONS AND

STANDARDS.

It is a requirement of Seeley International that all coolers be

wired with a dedicated circuit and circuit breaker/fuse at the

distribution board.

A mains isolation switch, with all pole disconnection, shall be

furnished by the contractor and installed adjacent to the cooler.

IMPORTANT! There are specic models for regional voltages

and frequencies which are not interchangeable. Specically, the

fan motor(s), transformer(s) and pump(s) may be unique to the

voltage/frequency of supply.

See the cooler rating label for the correct electrical data. Before

connecting the device, make sure the power supply matches

the cooler voltage and frequency.

Electrical Supply Specication (50Hz Option):

380-415V / 50 Hz / 3N~ / 4.9A (FLA)

Electrical Supply Specication (60Hz Options):

440-480V / 60 Hz / 3~ / 9A (FLA) 11.5A (MCA) 15A (MOPD)

200-240V / 60 Hz / 3~ / 11A (FLA) 14.5A (MCA) 20A (MOPD)

200-240V / 60 Hz / 1~ / 8A (FLA) 10.5A (MCA) 15A (MOPD)

Mains power terminals are provided inside the electrical cabinet

with glands provided for cable entry.

MOTOR LOCKED-ROTOR PROTECTION

Due to the built-in motor locked-rotor protection, the starting

current (LRA) is equal to or less than the nominal current (FLA).

FIRE TERMINALS

A pair of terminals labelled "FIRE" are provided for integration

with a building re management system.

These terminals provide power to the cooler controls and are

supplied with a bridge.

To use with a building management system, remove the bridge

and connect the terminals through a NORMALLY CLOSED

relay which opens in a re event.

Interrupting power to the PLC will immediately stop all cooler

components, including fans.

HIGH LEAKAGE CURRENT

IMPORTANT! High leakage current. Earth connection

essential before connecting supply.

The cooler utilises a fan motor with a built in inverter drive. To

comply with EMC regulations these drives adopt EMC lters

that connect to the motor earth terminals. The normal lter

leakage current to earth may accumulate to a total leakage

current in excess of 10mA. For asymmetrical power systems or

if a phase fails, the leakage current can increase to a multiple of

the nominal value.

To comply with regulations and to prevent electric shock this

leakage current must be properly addressed.

In particular, the earth terminal at the mains power point of

connection must be properly connected and earthed. Power

must not be applied until this is correctly completed.

RESIDUAL CURRENT CIRCUIT BREAKER

(RCCB)

The cooler utilises a fan motor with a built-in variable speed

drive (VSD). If local electrical standards require the use of a

residual current circuit breaker (RCCB), only AC/DC-sensitive

residual current devices (type B) are permissible. If incorrectly

selected and/or sized, pulsed charging currents from the

capacitors in the integrated EMC lter can lead to the instant

tripping of RCCB when the cooler power supply is switched on.

3~ MAINS

TERMINALS

FIRE

TERMINALS

24VDC POWER SUPPLY

The cooler is provided with a 24VDC switch mode power

supply for use with internal components and optional sensor

accessories. The maximum power available for external

components is 30W.

TRANSFORMER TAPPINGS

440-480V / 3~ coolers ONLY are tted with a transformer to

power the cooler electronics. By default the input voltage

jumper is set for 480V. If the power supply has a dierent

phase-to-phase voltage, reposition the jumper as per the table

below.

380-415V control box shown

PHASE TO PHASE

PRIMARY VOLTAGE

JUMPER

BETWEEN

380V 31 - 38

400V 32 - 38

415V 31 - 37

440V 32 - 37

460V 32 - 36

480V 33 - 36

16 | CW-H INSTALLATION, OPERATION & MAINTENANCE MANUAL 859749-J

WATER SUPPLY INSTALLATION

The cooler requires a permanent water supply to be

connected. A built-in Inlet Solenoid Valve, controlled by the

water management system, allows water into the cooler when

required.

INSTALLATION OF THE WATER SUPPLY MUST CONFORM

TO LOCAL PLUMBING RULES, REGULATIONS AND

STANDARDS.

The following specications for water supply are required:

Water Connections:

½” BSP (Aus/Eur), ½” NPT (USA) male.

Water Supply:

100kPa (15psi) - 800 kPa (115psi)

10L/min (2.6 gal/min) MINIMUM

20L/min (5.3 gal/min) RECOMMENDED

Water Supply Temperature:

40°C (105°F) MAXIMUM

Water Supply Salinity:

100 to 1150μS/cm

ILL1940-B

WATER REQUIREMENTS

WATER SUPPLY PRESSURE REGULATION

The Installer must provide a pressure regulator in the water

supply line adjacent to the cooler to regulate water supply

pressures between 100kPa (15 PSI) and 800kPa (115 PSI).

Important! Water pressures which are lower than 100kPa (15

PSI) will prevent the inlet solenoid valve from opening.

Important! Water pressures which are higher than 1200 kPa

(175 PSI) and/or water temperatures which are higher than

40ºC (105ºF) risk inlet solenoid valve failure.

Water pipes installed on the outside of a building, or any other

exposed location, shall have adequate insulation to protect

against freezing in the winter and solar radiation heating in the

summer.

If a non-return valve is installed in the water supply line, it

is recommended that a suitable pressure relief valve is also

installed between the cooler and the non-return valve to limit

the pressure rise associated with the heating eects of ambient

temperature and solar radiation.

WATER SUPPLY ISOLATION

The Installer must provide a manual 1/4 turn ball type shut o

valve (do not use a stop cock) in the water supply line adjacent

to the cooler, subject to local plumbing regulations. This allows

the water supply to be isolated whenever work needs to be

done on the cooler.

In areas where temperatures can cause water supply pipes

to freeze, a drain down facility should be provided during the

installation. This drain down facility must be activated prior

to freezing conditions to avoid possible damage to the cooler

components.

WATER SUPPLY FILTRATION

The Installer must provide an inlet water lter in the water

supply line, external to the cooler, to prevent any debris from

entering and damaging cooler components.

Important! Flush the water pipe to remove any contaminants

(swarf, lings or dirt) before nal tting. Contaminants can

lodge in the inlet solenoid valve, preventing it from functioning

correctly.

The cooler's water management system is designed to use

water that is suitable to be classied as ‘potable’ and t for

human consumption. If alternative water (including rain water) is

to be used that contains unusually high or low levels of salinity,

hardness, acidity or chemical contaminants, then additional

ltration or treatment systems should be employed to render the

water ‘potable’.

WATER HAMMER

Not all installation pipeworks are the same, and some may

require additional prevention against water hammer. If water

hammer is a problem, it is the responsibility of the Installer to t

an appropriate water hammer arresting device external to the

cooler.

WATER

INLET

WATER

DRAIN

CW-H INSTALLATION, OPERATION & MAINTENANCE MANUAL 859749-J | 17

WATER DRAIN INSTALLATION

The cooler requires a permanent water drain to be connected.

A built-in drain valve, controlled by the water management

system, releases water from the cooler when required.

INSTALLATION OF THE WATER DRAIN MUST CONFORM

TO LOCAL PLUMBING STANDARDS.

Drain Connections:

The cooler installation kit contains components to congure the

drain valve discharge to one of the following options:

- Down or Rear Discharge

- 1.5" (40mm) BSP Male or 1.5" Flexible Coupling.

Drain Rate:

15 L/min (4 gal/min)

Important! Water drained from the drain valve is high in salinity

and must be carried away to a suitable discharge point on the

building or property. Never drain the water directly onto the roof

ILL2442-E

ILL2442-E

ILL2443

The removable access panel should be re-assembled after

drain line installation.

Important! Drainage systems with long pipe runs, multiple entry

points, and/or incorporating traps shall use a tundish or similar

device to create a 25mm (1") air-gap between the bottom of the

drain valve and the drainage system.

ILL3938

WATER REQUIREMENTS

18 | CW-H INSTALLATION, OPERATION & MAINTENANCE MANUAL 859749-J

FAN SPEED MANAGEMENT SYSTEM

The cooler fan is driven by an electronically commutated DC

motor with integrated variable speed drives (VSD) that allows

for 0-10Vdc speed control.

The fan speed is controlled by the inputs from the Primary

Control Method (e.g. Multi-Magic Wall Controller). Depending

upon the control type, speed control is either continuously

variable or in 10 discrete speed steps (Speed 1-10).

If, when commanded to start, the fan start delay option is

enabled, the fan will remain o until the delay timer has expired.

Upon starting, the fan will initially run at a xed slow speed for

30 seconds before increasing to the requested speed.

If pre-wet is enabled, the supply fans will remain at the xed

slow speed until the pre-wet cycle is complete.

WATER MANAGEMENT SYSTEM

The cooler contains multiple parts to supply, distribute and

manage the water needed for the heat exchangers.

Water Inlet Solenoid Valve

The inlet solenoid valve allows water into the water reservoir. It

is open during the following phases.

• Initial Tank Fill

Trigger: Entering IEC or DEC mode.

• IEC Tank Fill

Trigger: Indirect Watering Cycle = TANK FILL.

• DEC Only Tank Fill

Trigger: Low Probe = WET.

Once open, the inlet solenoid valve will remain open until the

water high probe has detected water for at least 5 seconds.

If the water drain valve is open, the inlet solenoid valve will

remain closed.

Indirect Pump Control (IEC Watering Cycle)

The indirect pumps move water from the reservoir to the 3

indirect heat exchangers.

The indirect heat exchangers do not require continuous

watering and the pump runs on the following cycle

• Tank Level OK - Water lled to high probe and waiting for

next IEC pump cycle to start.

• Indirect Pump Running (60 seconds).

• Core Drain - IEC pump stopped and excess water is

draining back to the reservoir (1 minute 30 seconds)

• Tank Fill - IEC pump stopped and inlet solenoid valve open

and re-lling to high probe (6 minutes 30 seconds)

Total IEC pump on time = 1 minute

Total IEC pump o time = 8 minutes

Direct Pump Control (Supercool coolers only)

The direct pump moves water from the reservoir to the Chillcel®

media. When running in DEC mode the direct pump runs

continuously. Excess water from the Chillcel® media drains

back to the reservoir.

COOLER CONTROL COMPONENTS

Water Salinity Control

As water evaporates from the heat exchangers, the salinity of

the remaining water naturally increases.

The water management system uses the 3-pin water probe to

measure water conductivity as a proxy for salinity. The probe

can sense conductivity down to 9 µS (about 4ppm) .

Water conductivity is updated every time water reaches the high

probe and, when it exceeds the upper set point, a salinity drain

cycle will start.

Chlorinator Control

The chlorinator is composed of specially treated plates. When

energised and submerged in water, electrical current ows

between the plates generating chlorine which is known to kill

bacteria in water supplies.

The chlorinator is active when the cooler is in IEC mode, AND

the water level is above the bottom probe AND the water

conductivity is >1500 µs/cm.

If the water conductivity remains <1500µs/cm for 24 hours, a

clean tank drain cycle will start.

Water Tank (Reservoir) Drain Valve

The drain valve will automatically open when power is rst

applied to the cooler. It will close again when IEC or DEC mode

is enabled.

During a salinity drain cycle, the drain valve opens until the

water level falls below the low probe, then the drain valve

closes immediately, and inlet solenoid valve opens to rell the

reservoir with fresh water.

During a clean water drain cycle, the drain valve remains open

for 10 minutes, after which the inlet solenoid valve opens to rell

the reservoir with fresh water.

The drain valve will open if it has been 3 days since IEC or DEC

mode was last run.

CW-H INSTALLATION, OPERATION & MAINTENANCE MANUAL 859749-J | 19

CONTROL COMPONENTS

Cooler logic and controls are handled by a PLC in conjunction

with a Water Manager PCBA, both located in the controls

enclosure.

PLC

WATER MANAGER

PCBA

INPUT AND OUTPUT TERMINALS

A series of input and output terminals are located on the door of

the controls enclosure.

See MULTI-MAGIC CONTROLS for terminal functions.

COOLER CONTROL COMPONENTS

ILL3940

20 | CW-H INSTALLATION, OPERATION & MAINTENANCE MANUAL 859749-J

MULTI-MAGIC CONTROLS

MULTI-MAGIC PLC

ILL3622-A

10

6

1

2

3

4

5

7

8

9

Item Description Item Description

1

UP – moves cursor up to next

variable or increase value in

edit mode

6 Green LED – Power Status

2

DOWN – moves cursor down to

next variable or decrease value

in edit mode

7

Red LED – Fault Status.

Number of ashes indicates

fault code

3 RIGHT – opens the next page 8 Yellow LED

4

LEFT – opens the previous

page

9

Green LED – Flashes if wall

control/MODBUS primary is

connected

5 OK (ENTER) – select/edit value 10

USB Type A for USB memory

stick

ILL3622-A

Use the navigation LEFT/RIGHT buttons to switch between

the “CONTROL”, “MONITOR”, “SENSORS” and "HISTORY"

screens.

To return to the previous menu screen long press the LEFT

button

CONTROL SCREEN

This screen allows the user to select the cooler's primary input

control method, including controlling the cooler manually from

the PLC via Local Mode.

For all PLC screens:

• Use the navigation UP/DOWN buttons to scroll through the

options

• Push the OK button to edit the option.

• Use the UP/DOWN buttons to change the value of the option.

• Push the OK button again to conrm the selection and exit

edit mode.

ILL3624

Item Description Item Description

1

Primary Input Control Method;

LOCAL

WALL = Multi-Magic Wall Controller

BMS = Low Voltage BMS

Modbus

BACnet

4 PLC Software Revision

2

Cool Mode

Vent = Fan only.

Indirect = Fan & Indirect Evaporative

Cooling

Direct = Fan & Direct Evaporative

Cooling*

Supercool = Fan & Indirect & Direct

Evaporative Cooling*

5

Message Bar. Shows

current cooler status.

3

Fan Speed

If Control Method = Local; Sets Fan

Speed 0-10

Otherwise display 0-100% (BMS /

MODBUS)

or display 0-10 (Wall Controller /

BACnet)

6

Fault.

Displays if a fault condition

is active.

*NOTE. Direct Cool Mode and Supercool Mode are available for

Supercool enabled coolers only.

IMPORTANT! The cooler can only accept control inputs from

the one primary control method selected on the CONTROLS

screen, however control outputs are available to be read across

all methods.

For example, when Wall Controller is selected, the cooler will

only accept inputs (e.g. Fan Speed) from a Multi-Magic Wall

Controller, whereas outputs (e.g. Drain Valve status) can be

read by a 3rd party Modbus device.

CW-H INSTALLATION, OPERATION & MAINTENANCE MANUAL 859749-J | 21

MULTI-MAGIC CONTROLS

MONITOR SCREENS

These screens allows the user to see the status of the cooler

components.

ILL3623

Item Description Item Description

1

Displays status of the

Inlet Water Solenoid Valve.

Image shows running water

into tank when valve is open.

3

Displays status of the

Drain Valve. Image shows

water emptying from tank when

valve is open.

2

Displays the tank water level.

Image empty when water not

detected at low probe.

Image half full when water

detected at low probe only.

Image full when water detected

at both low and high probes.

4

Displays the status of the

pumps.

Image shows owing water

when the Indirect Pump (IEC)

and/or Direct Pump (DEC) is

running.

SENSOR SCREENS

These screens allow the user to congure up to four 0-10Vdc

input channels, labelled S1 to S4, for use with optional sensor

accessories.

Tag Description

Ambient Air Sensor

AMBNT-T Temperature, 0-10V, -40...+70C or -40...+158F

AMBNT-H Relative Humidity, 0-10V, 0...100% rh

Room Air Sensor

ROOM-T Temperature, 0-10V, 0...+50C or +32...+122F

ROOM-H Relative Humidity, 0-10V, 0...100% rh

Supply Air Duct Sensor

SPLY-T Temperature, 0-10V, 0...+50C or +32...+122F

SPLY-H Relative Humidity, 0-10V, 0...100% rh

Dierential Air Pressure Sensor

PRESSURE Pressure, 0-10V, 0....+500Pa or 0....+2.00"wg

Temperature and Relative Humidity sensors require two input

channels. When conguring the rst channel for Temperature,

the second channel is automatically congured for Relative

Humidity.

Pressure sensors require only one input channel.

Installing sensor accessories does not automatically activate

additional sensor functionality. Customers require a control

method (e.g. Multi-Magic Wall Controller or 3rd Party Building

Management System) to use the measured values as required.

See separate Installation Instructions for each type of sensor for

example functions.

ILL3710-C

HISTORY SCREENS

These screens allow the user to view time stamped records

of the coolers fault code history and water drain history Each

history can be reset by selecting the CLEAR button.

ILL3930

Item Description Item Description

1

Displays water salinity level

(µS/cm) measured by 3 pin

probe.

3

Water Manager PCBA Software

Revision

2

Displays status of the

Chlorinator. ON/OFF

OK

FAULT

4

Displays PWM of the

Chlorinator 0...100%

ILL3870

Item Description Item Description

1

Displays the status of the fan

motors.

0-10Vdc analogue output from

the PLC to the supply fan (SF)

2

CW-H Supply Fan (SF) Status

OK

FAULT

ILL3931

22 | CW-H INSTALLATION, OPERATION & MAINTENANCE MANUAL 859749-J

MULTI-MAGIC CONTROLS

CONTROL METHOD OPTION 1 (WALL)

MULTI-MAGIC WALL CONTROLLER (WALL)

The Multi-Magic Wall Controller,

(supplied separately) can control

up to a maximum of 15 Multi-

Magic coolers acting as a Primary

Controller over a Modbus RS-485

network.

It incorporates sensors to

automatically regulate local zone

temperature and relative humidity.

Ensure "WALL" is selected on the

CONTROL screen.

ILL3872

Push and hold the RIGHT

button until the password

screen is displayed.

Use the LEFT/RIGHT

and UP/DOWN buttons

to enter password “7378”

and push OK to display

the SETUP screen.

Use the UP/DOWN

buttons to select

COMMUNICATION and

push OK.

Use the UP/DOWN

buttons to select NODE

ADDRESS.

Push OK to activate the

eld.

Use the UP/DOWN

buttons to set a unique

value from 1 to 15 for each

cooler and push OK.

Note:

Baud Rate must be 38400

Parity must be NULL

Use the UP/DOWN

buttons to select SAVE.

Push OK to activate the

eld.

AFTER CHANGING

NODE ADDRESS, CYCLE

POWER TO COOLER TO

SAVE CHANGE.

Once set, the cooler

NODE ADDRESS

will appear on the

CONTROLS page.

SETTING DEVICE NODE ADDRESS (WALL)

When using the Multi-Magic Wall Controller, each cooler on the

RS-485 network requires a unique Node Address.

Refer to the RS-485 wiring rules section in this manual for

communication cable installation instructions and refer to

installation literature provided with the Multi-Magic Wall

Controller for additional setup instructions.

ILL3665

CW-H INSTALLATION, OPERATION & MAINTENANCE MANUAL 859749-J | 23

MULTI-MAGIC CONTROLS

The basic functions of cooler can be controlled via a 3rd Party

Modbus RS-485 Primary Controller.

Ensure "MOBUS" is selected on the CONTROL screen.

Modbus control registers are available for.

• Vent Mode

• IEC Cool Mode

• DEC Cool Mode*

• Fan Speed (0-100%)

• Fault Code Reset

• Manual Drain

*Note: DEC Cool Mode only operates on Supercool coolers

Additional read only registers are available for monitoring the

status of the connected coolers. See Appendix C for the full

register list.

Refer to the RS-485 wiring rules section in this manual for

communication cable installation instructions

CONTROL METHOD OPTION 2 (MODBUS)

3rd PARTY MODBUS RS-485 PRIMARY CONTROL

ILL3743

Use the LEFT/RIGHT

and UP/DOWN buttons

to enter password “7378”

and push OK to display

the SETUP screen.

Use the UP/DOWN

buttons to select

COMMUNICATION and

push OK.

Use the UP/DOWN

buttons to and push OK

to activate the available

elds.

Set a unique NODE

ADDRESS from 1 to 99 for

each cooler.

Set BAUD RATE and

PARITY values to match

the Primary Modbus

Controller.

Once nished select

SAVE.

Push OK

AFTER CHANGING

COMMUNICATION

SETTINGS, CYCLE

POWER TO COOLER TO

SAVE CHANGE.

Once set, the cooler

NODE ADDRESS

will appear on the

CONTROLS page.

COMMUNICATION SETUP (MODBUS)

All secondary devices (coolers) on the Modbus RS-485 network

requires a unique Node Address and communication setting

which match the 3rd Party Primary Controller.

Push and hold the RIGHT

button until the password

screen is displayed.

ILL3904

24 | CW-H INSTALLATION, OPERATION & MAINTENANCE MANUAL 859749-J

MULTI-MAGIC CONTROLS

The basic functions of cooler can be controlled via BACnet

using either BACnet MS/TP or BACnet IP protocols.

Ensure "BACNET" is selected on the CONTROL screen.

BACnet control objects are available for.

• Cooler ON/OFF

• Vent Mode

• IEC Cool Mode

• DEC Cool Mode (Supercool only)

• Fan Speed (0-10)

• Fault Code Reset

• Manual Drain

Additional monitoring objects are available for the status of the

connected coolers. See Appendix D for the full object list.

CONTROL METHOD OPTION 3 (BACNET)

3rd PARTY BACnet MS/TP or BACnet IP PRIMARY CONTROL

ILL3905

ILL3906

Push and hold the RIGHT

button until the password

screen is displayed.

Use the LEFT/RIGHT

and UP/DOWN buttons

to enter password “7378”

and push OK to display

the SETUP screen.

Use the UP/DOWN

buttons to select

COMMUNICATION and

push OK.

Use the LEFT/RIGHT and

UP/DOWN buttons to

1. Select either BACnet

MS/TP or BACnet IP

BACNET PROTOCOL SELECTION

ILL3907

BACNET MS/TP COMMUNICATION SETUP

BACNET IP COMMUNICATION SETUP

ILL3908-A

Note. Only one BACnet protocol may be active at a time.

With BACnet MS/TP

selected.

Use the UP/DOWN

buttons to set a unique

DEVICE ID from 1 to 99

for each cooler.

Press RIGHT button.

Set BAUD RATE and

PARITY values to match

the BACnet Controller.

Once nished, select

SAVE.

Push OK

AFTER CHANGING

COMMUNICATION

SETTINGS, CYCLE

POWER TO COOLER TO

SAVE CHANGE.

With BACnet IP selected

Use the UP/DOWN

buttons to set a unique

DEVICE ID from 1 to 99

for each cooler.

Press RIGHT button.

Set a unique Ethernet IP

ADDRESS for each cooler.

Set GATEWAY, NETMASK

ADDRESS, and IP PORT

to match the BACnet

Controller.

Once nished, select

SAVE.

Push OK

AFTER CHANGING

COMMUNICATION

SETTINGS, CYCLE

POWER TO COOLER TO

SAVE CHANGE.

CW-H INSTALLATION, OPERATION & MAINTENANCE MANUAL 859749-J | 25

RS-485 NETWORK SETUP

The Multi-Magic Wall Controller, 3rd Party MODBUS and

BACnet MS/TP control options all use the RS-485 serial

protocol.

RS-485 CABLE SPECIFICATIONS

The Installer must supply communication cable between the

primary controller and connected coolers to the following

specication.

• Suitable for RS-485 applications

• Minimum 1 twisted pair (TP) and a third conductor

• Copper conductors

• 0.5 mm

2

/ AWG 20

• Braided shield with drain wire

• Characteristic impedance 120Ω

• Nominal capacity between conductors 89 pF/m

• Nominal capacity between conductors and shielding 161pF/m

Note: Non-shielded cables are not protected against

electromagnetic interference which can cause signal

degradation.

ILL3705-B

RS-485 CABLE WIRING RULES

The following rules must be applied when setting up a RS-485

network:

• Communication wiring must be kept separate from AC power

wiring.

• Always route communication cables at least 300mm (12”)

away from high voltage cables and high-power machines.

• Crossover high power cables at right angles.

• Maximum cable length from Wall Controller / Primary to rst

cooler is 100m (330ft).

• Maximum cable length between each cooler is 100m (330ft).

• Coolers must be connected in daisy-chain style, not star or

multi-drop..

RS-485 CABLE CONNECTIONS

The RS-485 serial terminals are located on the inside of the

control enclosure door.

Use the twisted pair for the ‘+’

and ‘-‘ signal terminals.

Use the 3rd conductor for the

signal GND terminals.

Attach the braided shield / drain

wire to the EARTH point at one

end only.

MODBUS RS-485 Terminal Details

Type Push-In

Stripping Length 8 mm - 10 mm / 5/16" - 3/8"

Cable Termination Ferrule with plastic sleeve

2x Conductors Cross Section (Flexible) 0.5 mm

2

/ 20 AWG

MULTI-MAGIC CONTROLS

RS-485 TERMINATING RESISTORS

Daisy-chained RS-485 networks require two 120Ω terminating

resistors, one at the start and one at the end of the

communication chain.

Attach a 120Ω terminating resistor between the "+" and "-"

terminals on the Primary Controller (e.g. Wall Controller)

Attach a 120Ω terminating resistor between the "+" and "-"

terminals on the last cooler on the network.

Do not t a 120Ω terminating resistor to coolers installed

between the Primary Controller and the last cooler.

ILL3677-B

See Appendix A for an example wiring schematic.

ILL3888-A

RJ45 ETHERNET SETUP

The BACnet IP (BCN) control option uses the RJ45 ethernet

port, located on top of the Multi-Magic PLC.

ETHERNET CABLE SPECIFICATIONS

The Installer must supply ethernet cable between the primary

controller and connected coolers to the following specication.

• Cat 5, 5e, 6 or 6e shielded

ETHERNET CABLE WIRING RULES

• Maximum single cable length between devices is 100m.

• Each cooler has a single RJ45 ethernet port, so an ethernet

switch or router is required

ILL3909-A

26 | CW-H INSTALLATION, OPERATION & MAINTENANCE MANUAL 859749-J

ID TYPE FUNCTION

FAULT

DIGITAL OUTPUT

DRY CONTACT

Fault Output. Congurable

NC or NO. See Settings

FAULT

BMS GND GROUND

BMS SPD

ANALOGUE INPUT

0-10Vdc

Fan Speed Input

BMS IEC

DIGITAL INPUT

DRY CONTACT

Cooler Operating Mode. See

Logic Table

BMS DEC

DIGITAL INPUT

DRY CONTACT

MULTI-MAGIC CONTROLS

BMS CONTROL INPUTS

The cooler operating mode is set via the IEC, DEC and SPD

input terminals with the following logic.

PRIMARY

CONTROL

METHOD

COOLER FUNCTION

IEC

TERMINAL

DEC

TERMINAL

SPD (Vdc)

TERMINAL

BMS OFF FALSE FALSE 0

BMS VENT FALSE FALSE >1.3

BMS INDIRECT COOL ONLY TRUE FALSE >1.3

BMS DIRECT COOL ONLY* FALSE TRUE >1.3

BMS INDIRECT & DIRECT COOL TRUE TRUE >1.3

BMS CLEAR FAULT FALSE FALSE

0.9 - 1.3 for

10 seconds

BMS MANUAL DRAIN FALSE FALSE

0.5 - 0.9 for

10 seconds

W/C VENT FIXED LOW SPEED TRUE FALSE N/A

W/C VENT FIXED HIGH SPEED FALSE TRUE N/A

*Note: DEC Cool Mode only operates on Supercool coolers

Warning: The BMS IEC and DEC input terminals are non-

isolated dry contacts. Do not apply an external power supply,

instead use a switch to connect the input terminal to the BMS

GND terminal.

BMS FAN SPEED INPUT

The cooler fan speed is set by applying an analogue 0-10Vdc

signal to the Fan Speed Input terminal, with the following logic;

BMS FAN SPEED

MINIMUM VOLTAGE MAXIMUM VOLTAGE

Vdc Vdc

OFF 0.00 1.29

1 1.30 1.79

2 1.80 2.69

3 2.70 3.59

4 3.60 4.49

5 4.50 5.39

6 5.40 6.29

7 6.30 7.19

8 7.20 8.09

9 8.10 8.99

10 9.00 10.00

BMS CABLING REQUIREMENTS

To avoid signal degradation use shielded, properly grounded

cables for all analogue and digital inputs and outputs. Route

input and output cables separately from high voltage power

cables. Interconnection wiring shall be separated by reinforced

insulation to any live parts.

See Appendix B for an example BMS wiring schematic.

BMS Terminal Details

Type Push-In

Stripping Length 8 mm - 10 mm / 5/16" - 3/8"

Cable Termination Ferrule with plastic sleeve

2x Conductors Cross Section (Flexible) 0.5 mm

2

/ 20 AWG

The basic functions of cooler can be controlled via a low voltage

Building Management System and the series of terminals

located on the control enclosure door. Ensure "BMS" is selected

on the CONTROL screen.

ILL3681

CONTROL METHOD OPTION 4 (BMS)

LOW VOLTAGE BUILDING MANAGEMENT SYSTEM

BMS FAULT OUTPUT

The fault output is a pair of dry contact terminals which can be

used to switch an external power supply.

Maximum Voltage: 250 Vac

Maximum Current: 3A

Minimum Switching Capacity: 100mA / 5Vdc

The fault output can be congured to be Normally Open (close

in Fault state) or Normally Closed (open in Fault state). See the

Commissioning Section for instructions on how to set.

The output is available for use in all Primary Control Methods,

not just BMS. For example, a Wall Controller can be used for

local zone control, with the fault signal monitored by a central

building management system.

CW-H INSTALLATION, OPERATION & MAINTENANCE MANUAL 859749-J | 27

MULTI-MAGIC CONTROLS

The basic functions of cooler can be manually controlled from

the CONTROL screen. This mode is recommended for initial

setup and servicing only.

Ensure "LOCAL" is selected on the CONTROL screen.

Select the required COOL-MODE

• Vent = Fan only.

• Indirect = Fan & Indirect Evaporative Cooling

• Direct = Fan & Direct Evaporative Cooling*

• Supercool = Fan & Indirect & Direct Evaporative Cooling*.

For all modes, set the SPEED between 0 and 10 to run the fan.

*Note: Direct and Supercool Mode only operates on Supercool

coolers.

ILL3682

CONTROL METHOD OPTION 5 (LOCAL)

PLC LOCAL CONTROL

MANUAL DRAIN

All control modes provide an option to complete a manual tank

drain.

When triggered, the drain valve will open and stay open for at

least 10 minutes.

During this period, all pumps will stop and the inlet solenoid

valve will remain closed, however the fan will continue to run at

the requested speed.

Once triggered, it is not possible to close the drain valve again

until the 10 minutes as elapsed.

After 10 minutes the cooler will resume running in requested

operating mode.

ILL3910

To start a Manual Drain select the button under the tank icon on

the MONITOR-TANK screen.

FREEZE PROTECTION

When a Multi-Magic Ambient Sensor is installed, the Freeze

Protection function is automatically enabled.

When the ambient temperature is measured below 5

o

C (41

o

F)

for 20 minutes freeze protection mode is enabled.

Once enabled, the drain valve will open, all pumps will stop and

the inlet solenoid valve will remain closed, however the fan will

continue to run at the requested speed.

Once the ambient temperature is measured above 5

o

C (41

o

F)

for 20 minutes freeze protection mode will be deactivated and

the cooler will resume running in requested operating mode.

28 | CW-H INSTALLATION, OPERATION & MAINTENANCE MANUAL 859749-J

MULTI-MAGIC CONTROLS

IEC

CHANGING COOLER SETTINGS

Push and hold the RIGHT

button until the password

screen is displayed.

Use the navigation LEFT/

RIGHT and UP/DOWN buttons

to enter password “7378” and

push OK to display the SETUP

screen.

Use the navigation UP/DOWN

buttons to move the cursor to

SETTINGS and push OK.

Use the navigation LEFT/

RIGHT buttons to move

between Pages 1, 2 and 3.

Use the navigation UP/DOWN

buttons to move the cursor to

the required setting.

Push OK to activate the eld.

Use the navigation UP/DOWN

buttons to set a unique value.

Push OK to save the setting

Long press LEFT to return to

the previous screen.

PRE-WET

Upon cooler start-up, Pre-Wet rst ensures the water tank is full

and then runs an extra 6-minute start up pump cycle to saturate

the heat exchanger cores.

During this Pre-Wet phase, the supply fan will be restricted to

Speed 1 regardless of controller input.

Pre-Wet ensures only cooled air is delivered, at the expense of

a longer start up time.

The Pre-Wet sequence will run again if the pumps have not run

in the last 30 minutes.

FAN START DELAY & RUN OUTPUT

RELAY

The Fan Start Delay can be a positive or negative timer.

If a positive timer is selected, the fan run output relay changes

state but the fan does not start until the timer has expired.

For example, this can be used to open or close 3rd party

dampers before the cooler fans start.

If a negative timer is selected, the fans start when requested,

but the fan run output relay does not change state until the timer

has expired.

For example, this can be used to ensure internal building

pressure is maintained before opening 3rd party relief vents.

IEC

USER SELECTABLE

-30s, -60s, -90s, -120s

RELAY OUTPUT

USER SELECTABLE

N/C or N/O

The fan run output is a pair of dry contact terminals which can

be used to switch an external power supply.

Maximum Voltage: 250 Vac

Maximum Current: 3A

Minimum Switching Capacity: 100mA / 5Vdc

The fan run output can be congured to be Normally Open

(close in when fan runs) or Normally Closed (open when fan

runs).

The output is available for use in all Primary Control Methods,

FAN SPEED INPUT

FAN RUN

SETTING VALUES

LANGUAGE

English (Default)

Spanish

Italian

French

Portuguese

PRE-WET

Enabled

Disabled (Default)

SALINITY DRAIN SET POINT

4275 uS/cm (Default)

2305 uS/cm

BMS FAULT STATE OUTPUT LOGIC

Normally Open (Default)

Normally Closed

SENSOR UNITS

Metric (Default)

Imperial

DATE TIME

Set for use with Fault Codes and Drain

History

FAN START DELAY

0s (Default)

-120s, -90s, -60s, -30s

+30s, +60s, +90s, +120s

FAN RUN OUTPUT LOGIC

Normally Open (Default)

Normally Closed

BMS LOCK SPEED

HIGH: 0-10 (Default 0)

LOW: 0-10 (Default 0)

FAN SPEED INPUT

RELAY OUTPUT

USER SELECTABLE

N/C or N/O

FAN RUN

ILL3678

USER SELECTABLE

+30s, +60s, +90s, +120s

CW-H INSTALLATION, OPERATION & MAINTENANCE MANUAL 859749-J | 29

MULTI-MAGIC CONTROLS

MESSAGE BAR CONTENTS

The MESSAGE BAR contains useful information about the

current cooler state.

The MESSAGE BAR will cycle through all active messages.

MESSAGE DESCRIPTION

STANDBY

Cooler is ON but no control input

active.

VENT MODE

Fan is running but no cooling stage

is on.

TANK INITIAL FILL

Inlet Water Solenoid is on and water is

entering the tank. Pumps will not start

until the tank is full.

PRE-WET FS LIMITED

Pre-Wet is enabled. The pumps are

running for an extra 6 minutes whilst

the fan speed is limited.

FAN START DELAY

Fan start delay is enabled. Fans will

start after the delay timer has expired.

INDIRECT PUMP RUNNING

IEC COOL MODE

IEC pump is running. Pump cycles

ON for 60 seconds and OFF for 100

seconds.

CORE DRAIN

IEC COOL MODE

IEC pump have just turned OFF and

water is returning back to tank.

TANK FILL-IEC

IEC COOL MODE

Inlet Water Solenoid is on and water is

entering the tank.

TANK LEVEL OK

IEC COOL MODE

Tank is full, waiting for IEC pumps to

start.

TANK FILL-DEC

DEC COOL MODE

Inlet Water Solenoid is on and water is

entering the tank.

DIRECT PUMP RUNNING

DEC COOL MODE

DEC pump is running. Pump runs

continuously.

SALINITY DRAIN

Tank water has reached the maximum

salinity level and a partial tank drain

and ll cycle is in progress.

CLEAN WATER DRAIN

The chlorinator has not run for 24

hours and a complete tank drain and ll

cycle is in progress.

TANK DRAIN

3-day tank drain delay or manual drain

triggered.

FREEZE PROTECTION

The tank has drained to prevent water

freezing.

REMOTE SHUTDOWN

Multi-Magic Wall Controller has been

locked by a BMS input. Refer to Wall

Controller manual.

BMS LOCK HIGH SPEED

Multi-Magic Wall Controller has been

locked by a BMS input to VENT Mode

Refer to Wall Controller manual.

BMS LOCK LOW SPEED

Multi-Magic Wall Controller has been

locked by a BMS input to VENT Mode

Refer to Wall Controller manual.

BMS LOCK SPEED

BMS Lock is a special mode for use with a Multi-Magic Wall

Controller.

When Wall Controller is selected as the Primary Control

Method, use the BMS IEC or DEC input terminals on any

connected cooler to remotely lockout the Wall Controller.

When applied, no cooler control from the Wall Controller is

possible and the cooler can be congured to either shutdown or

run in VENT mode at one of two dierent xed speeds

For example, if low speed is set to 3 and high speed is set to 8.

LOW SPEED

SETTING

(0-10)

HIGH SPEED

SETTING

(0-10)

IEC

TERMINAL

DEC

TERMINAL

COOLER

FUNCTION

0 0 FALSE TRUE SHUTDOWN

0 0 TRUE FALSE SHUTDOWN

0 0 TRUE TRUE SHUTDOWN

3 8 TRUE FALSE VENT SPEED 3

3 8 FALSE TRUE VENT SPEED 8

This feature may be useful when Building Managers wish

to remotely shutdown coolers during certain hours, enable

overnight building purges or when Climate Wizard products are

used as blowers for in line heaters during the winter season.

For groups of coolers running from a single Wall Controller

• Each cooler can be set to run at dierent BMS Lock Speeds.

• The IEC and/or DEC input can be applied to any single cooler

in the group and all coolers will enter BMS Lock Mode.

ILL3936

30 | CW-H INSTALLATION, OPERATION & MAINTENANCE MANUAL 859749-J

MULTI-MAGIC CONTROLS

TRI-COLOUR

LED

RED LED

ILL3686-A

ILL3686-A

OPERATION PHASE LED STATE

INITIAL BOOT UP.

FIRST 30-45 SECONDS AFTER

POWER UP

RED ON

TRI-COLOUR FLASHING GREEN

NORMAL RUNNING

RED ON

TRI-COLOUR ON AMBER

Note: Both PCBA LEDs are continuously ON once

communication between the PLC and PCBA has been

established.

WATER MANAGER LED STATES FAULT CODE DISPLAY

Active Fault Codes will cause

the FAULT button to appear on

the CONTROLS page.

Selecting the FAULT button

will open the ACTIVE FAULTS

page, listing all the current

active faults.

Select the INFO button to

display a QR code.

Scanning the QR Code will

direct users to the Seeley

Service Technical Support

website.

Select the RESET button to reset each active fault. Cycle the

cooler power to reset all active faults.

All faults are added to the FAULT CODE HISTORY screen.

On all screens, long press the LEFT button to return to the

CONTROL page.

ILL3653

CW-H INSTALLATION, OPERATION & MAINTENANCE MANUAL 859749-J | 31

FAULT CODE DESCRIPTIONS

MULTI-MAGIC CONTROLS

All faults below shut the cooler down unless stated.

Fault codes labelled as Running Faults will allow the cooler to continue to run, however performance may be reduced.

FAULT

CODE

FAULT DESCRIPTION SUGGESTED REMEDY

Fault Code 1 PLC – PCBA COMMUNICATION FAILURE

Cooler PLC has lost communication with PCBA tted inside

control box for at least 1 minute.

Check LED status on PCBA.

Check communication wiring between PLC and PCBA

Replace PCBA

Fault Code 2 FAILURE TO DETECT WATER AT LOW PROBE

No water at low probe 20 minutes after solenoid valve opening.

Check water supply on.

Check solenoid valve open.

Check drain valve closed.

Check water management probe position relative to drain valve overow.

Clean water management probe.

Fault Code 3 FAILURE TO DETECT WATER AT HIGH PROBE

No water at high probe 30 minutes after water detected at low

probe.

Check water supply on.

Check solenoid valve open.

Check water management probe position relative to drain valve overow.

Clean water management probe.

Check water supply pressure sucient to maintain tank capacity.

Fault Code 4 FAILURE TO CLEAR LOW PROBE DURING DRAIN

Water still detected at low probe 20 minutes after drain opened.

Check drain valve open.

Check drain pipework not blocked.

Check solenoid valve closed.

Clean water management probe.

Fault Code 5 WATER DETECTED AT HIGH PROBE BUT NOT LOW PROBE

Water still detected at high probe 30 minutes after water not

detected at low probe.

Clean water management probe.

Fault Code 7 SUPPLY MOTOR ERROR

Motor has been in fault state for at least 1 minute.

Check Motor Power Cable connections.

Check Motor Communications Cable connections.

Check MONITOR screen to identify which motor is in fault.

Fault Code 10 CHLORINATOR FAULT

Chlorinator has reached end of life or is experiencing a short

circuit. Running Fault

Check cooler PLC ashing LEDs for fault type.

Check no debris between chlorinator plates.

Replace Chlorinator

Fault Code 11 ROOM AIR SENSOR FAULT

Temperature or Relative Humidity input value has been 0V or

10V for at least 10 minutes. Running Fault

Check Sensor values at PLC cooler screen “SENSORS” menu

Check Sensor wiring

If no Sensor tted, check Sensor has not been accidentally enabled on Wall Controller

and/or PLC

Fault Code 12 AMBIENT AIR SENSOR FAULT

Temperature or Relative Humidity input value has been 0V or

10V for at least 10 minutes. Running Fault

Check Sensor values at PLC cooler screen “SENSORS” menu

Check Sensor wiring

If no Sensor tted, check Sensor has not been accidentally enabled on Wall Controller

and/or PLC

Fault Code 14 DUCT AIR SENSOR FAULT

Temperature or Relative Humidity input value has been 0V or

10V for at least 10 minutes. Running Fault

Check Sensor values at PLC cooler screen “SENSORS” menu

Check Sensor wiring

If no Sensor tted, check Sensor has not been accidentally enabled the PLC.

Fault Code 15 PRESSURE SENSOR FAULT

Pressure input value has been 0V or 10V for at least 10 minutes

whilst the fans fan been running. Running Fault.