Copyright © 2001 American Industrial Heat Transfer, Inc.

Shell & Tube Heat Exchangers Air Cooled Heat Exchangers

Visit our web site at

www.aihti.com

®

INSTALLATION & MAINTENANCE MANUAL

2001

Shell & tube cut-away and standard features ...................Page 2

Shell & tube installation & maintenance instructions ......Page 3

Shell & tube maintenance & schematic ...........................Page 4

Shell & tube piping diagram ............................................Page 5

Shell & tube accessories ..................................................Page 6

Air cooler general installation and maintenance ..............Page 7-8

Table of Contents

AOCS piping hook-up ................................Page 9

AC, AOCH, EOC, ACA piping hook-up ....Page 10

AOM, BM, LP, AOMF piping hook-up ......Page 11

Air cooler accessories ................................Page 12

Terms and conditions of sale ......................Page 13-15

Available products ......................................Page 16

Copyright © 2001 American Industrial Heat Transfer, Inc.

1- MOUNTING BRACKET

Heavy gauge steel mounting brackets are adjustable in

orientations to 360 degrees.

2- BONNET

Provides fluid into tubes with minimum restriction. One,

two, or four pass interchangeability.

3- FLOW CAVITY

Generously sized to allow for minimum pressure drop

and more uniform flow.

4- TUBES JOINT

Roller expanded tube joint to integral forged hub.

5- TUBES SHEET

Precision-machined tube-sheet provides for long last-

ing high strenght service.

6- THREAD

CNC precision threading to provide accurate leakproof

connections.

7- BAFFLES

CNC manufactured baffles to provide maximum turbu-

lence and heat transfer with a minimum fluid pressure

drop.

8- FINISH

Gray semigloss enamel suitable for outdoor service.

Can be used as a base for additional coats.

9- SHELL & TUBE BUNDLE ASSEMBLY

CNC precision manufactured parts to guarantee a close

fit between the baffles, tubes, and shell. Clearances are

minimized to provide for maximum heat transfer.

10- HUB

Premium quality forging with full opening designed

for minimum pressure drop.

11- FULL FACE GASKET

Full-face composite gasket for maximum pressure

and temperature.

12- DRAIN PORT

Drain ports allow for easy draining of tube side.

Optional zinc anode can be inserted in place of plug.

Note: Standard Feature descriptions are qualified by

and subject to product specifications which are avail-

able from American Industrial upon request.

1

2

3

4

6

7

8

9

10

11

12

1

2

3

4

6

7

9

10

11

12

8

1

2

3

4

6 7

8

9

11

12

AB , AB-2000, SAE, STS & EAB

SERIES

AA , STA & FBF

SERIES

CS , STC & CK

SERIES

SHELL & TUBE HEAT EXCHANGERS STANDARD FEATURES

5

2

Copyright © 2001 American Industrial Heat Transfer, Inc.

SHELL & TUBE GENERAL INSTALLATION & MAINTENANCE

Receiving

a) Inspect unit for any shipping damage before uncrating. Indicate

all damages to the trucking firms' delivery person, and mark it on

the receiving bill before accepting the freight. Make sure that there

is no visible damage to the outside surface of the heat exchanger.

Since the warranty is based upon the unit date code located on the

model identification tag, removal or manipulation of the identifi-

cation tag will void the manufacturers warranty.

b) When handling the shell & tube heat exchanger, special care

should be taken to avoid dropping the unit since mishandling could

cause the heat exchanger to crack and leak externally. Mishandling

of the unit is not covered under the manufacturers warranty. All

units are shipped with partial wood/corrugated cardboard contain-

ers for safe handling.

c) Standard Enamel Coating: American Industrial provides its stan-

dard products with a normal base coat of oil base air cure enamel

paint. The enamel paint is applied as a temporary protective and

esthetic coating prior to shipment. While the standard enamel coat-

ing is durable, American Industrial does not warranty it as a long-

term finish coating. It is strongly suggested that a more durable

final coating be applied after installation or prior to long-term stor-

age in a corrosive environment to cover any accidental scratches,

enhance esthetics, and further prevent corrosion. It is the responsi-

bility of the customer to provide regular maintenance against chips,

scratches, etc... and regular touch up maintenance must be pro-

vided for long-term benefits and corrosion prevention.

d) Special Coatings: American Industrial offers as customer op-

tions, Air-Dry Epoxy, and Heresite (Air-Dry Phenolic) coatings at

additional cost. American Industrial offers special coatings upon

request, however American Industrial does not warrantee coatings

to be a permanent solution for any equipment against corrosion. It

is the responsibility of the customer to provide regular maintenance

against chips, scratches, etc... and regular touch up maintenance

must be provided for long-term benefits and corrosion prevention.

Installation

a) American Industrial recommends that the equipment supplied

should be installed by qualified personnel who have solid under-

standing of system design, pressure and temperature ratings, and

piping assembly. Verify the service conditions of the system prior

to applying any shell & tube heat exchanger. If the system pressure

or temperature does not fall within the parameters on model rating

tag located on the heat exchanger, contact our factory prior to in-

stallation or operation.

b) Plan the installation to meet the requirements indicated on the

piping installation diagram as illustrated (page 4). It is recommended

to put the hot fluid to be cooled through the shell side and the cold

fluid through the tube side. The indicated port assembly sequence

in the diagram maximizes the performance, and minimizes the pos-

sibility of thermal shock. In instances where the fluids are required

to be reversed, hot fluid in the tubes and cold fluid in the shell the

heat exchanger will work with reduced performance.

c) When installing a series EAB heat exchanger (expansion bel-

low), it is recommended to use a shoulder bolt to allow the heat

exchanger to move freely while expanding and contracting due to

high differential temperatures.

d) It is recommended to use flexible hose wherever possible to

reduce vibration and allow slight movement. However, hoses are

not required. Hydraulic carrying lines should be sized to handle

the appropriate flow and to meet system pressure drop require-

ments based upon the systems parameters, and not based upon the

units supply and return connection size. We recommend that a low

cracking pressure direct acting relief valve be installed at the heat

exchanger inlet to protect it from pressure spikes by bypassing oil

in the event the system experiences a high flow surge. If preventa-

tive filtration is used it should be located ahead of the cooler on

both shell and tube side to catch any scale or sludge for the system

before it enters the cooler. Failure to install filters ahead of the heat

exchanger could lead to possible heat exchanger failure due to high

pressure if the system filters plug.

e) Standard shell & tube coolers are built with a rolled tube-sheet

construction. However, the differential operating temperature be-

tween the entering shell side fluid and the entering tube side fluid

should not exceed 150°F. If this condition exists, a severe thermal

shock could occur leading to product failure and mixing of the

fluids. For applications with a differential temperatures of 150°F

or more, we recommend using a series with a floating tube-sheet,

u-tube, or expansion joint to reduce the potential for the effects of

thermal shock.

g) Water requirements vary from location to location. If the source

of cooling water is from other than a municipal water supply, it is

recommended that a water strainer be installed ahead of the heat

exchanger to prevent dirt and debris from entering and clogging

the flow passages. If a water modulating valve is used it is recom-

mended to be installed at the inlet to the cooler to regulate the

water flow.

h) For steam service, or other related applications, please consult

our engineering department for additional information.

Maintenance

a) Inspect the heat exchanger for loosened bolts, connections, rust

spots, corrosion, and for internal or external fluid leakage. Any

corroded surfaces should be cleaned and recoated with paint.

b) Shell side: In many cases with clean hydraulic system oils it will

not be necessary to flush the interior of the shell side of the cooler.

In circumstances where the quality of hydraulic fluid is in ques-

tion, the shell side should be disconnected and flushed on a yearly

basis with a clean flushing oil/solvent to remove any sludge that

has been deposited. For severe cases where the unit is plugged and

cannot be flushed clean with solvent, the heat exchanger should be

replaced to maintain the proper cooling performance.

c) Tube side: In many cases it will be necessary to clean the tube

side of the heat exchanger due to poor fluid quality, debris, cal-

cium deposits, corrosion, mud, sludge, seaweed, etc.... To clean

3

Copyright © 2001 American Industrial Heat Transfer, Inc.

the tube side, flush with clean water or any good quality commer-

cial cleaner that does not attack the particular material of construc-

tion. With straight tube heat exchangers you can use a rod to care-

fully push any debris out of the tubes.

d) Zinc anodes are normally used to reduce the risk of failure due

to electrolysis. Zinc anodes are a sacrificial component designed

to wear and dissolve through normal use. Normally, zinc anodes

are applied to the water supply side of the heat exchanger. Depend-

ing upon the amount of corrosive action, one, two, three, or more

anodes can be applied to help further reduce the risk of failure.

American Industrial Heat Transfer, Inc. offers zinc anodes as an

option, to be specified and installed at the request our customers. It

is the responsibility of the customer to periodically check and verify

the condition of the zinc anode and replace it as needed.

Applications vary due to water chemical makeup and quality, ma-

terial differences, temperature, flow rate, piping arrangements, and

machine grounding. For those reasons, zinc anodes do not follow

any scheduled factory predetermined maintenance plan moreover

they must be checked routinely by the customer, and a mainte-

nance plan developed based upon the actual wear rate.

If substantial wear occurs or zinc dissolves without replacement,

premature failure or permanent damage may occur to the heat ex-

changer. American Industrial does not warranty customer applica-

tions. It is the responsibility of the customer to verify and apply the

proper system materials of construction and overall system require-

ments. Failures resulting from properly applied or misapplied use

of zinc anode(s) into non-specified or specified applications will

be the sole responsibility of the customer.

e) A routine maintenance schedule should be developed and ad-

justed to meet your systems requirements based upon water qual-

ity, etc….Failure to regularly maintain and clean your heat ex-

changer can result in a reduction in operational performance and

life expectancy.

SHELL & TUBE GENERAL INSTALLATION & MAINTENANCE

3/8" NPT Thread

1.84"

1.00"

0.86"

0.50"ø

0.75"

1/2" NPT Thread

2.70"

1.15"

0.63"ø

1.00" 1.75"

3/8" NPT Zinc Anode

PN: 301-0004

AB-400 thru AB-1000

AA-400 thru AA-1000

CS-600 thru CS-1000

1/2" NPT Zinc Anode

PN: 301-0003

AB-1200 thru AB-2000

AA-1200 thru AA-1600

CS-1200 thru CS-1700

Return Line

Relief Valve

Return Line

Filter

Heat

Exchanger

Y Strainer

Water Modulating Valve

To Tower

Or Drain

TUBE SIDE PASSES

The number of passes (SP,TP &FP) refers to the number of runs

back and forth of the cooling fluid on the tube side of the heat

exchanger. Tube passes are normally determined by the rate (gpm)

of water available to be used for cooling purposes (see table E).

The purpose of multi-passes are to increase turbulence by increas-

ing the velocity. Normally tube side passes will not affect pricing.

TABLE E- Flow Rate for Tube Side

Shell Liquid Flow - Tube Side

dia . SP TP FP

Code Min. Max. Min. Max. Min. Max.

400 3.5 21 –– –– –– ––

600 7.5 48 3.5 24 2 12

700 9 61 4.5 30 2.2 15

800 10 50 4.5 38 3 21

1000 20 120 10 70 5.0 37

1200 30 250 15 112 7.5 56

1600 57 460 29 180 14 90

1700 57 300 29 180 14 90

2000 90 650 45 320 25 160

TYPICAL HYDRAULIC CIRCUIT

with water cooled heat exchanger

4

Copyright © 2001 American Industrial Heat Transfer, Inc.

SHELL & TUBE PIPING HOOK-UP

URCSR Series

UCSR Series

Vent Port

Condensate out

Steam In

Fluid Out

Fluid In

Mounting

Air Out

Water In

Water Out

Drain Port

Air In

Mounting

(Both Sides)

C

B

B

B

A

A

A

D

D

D

C

C

C

B

B

B

A

A

A

D

D

C

D

C

ONE PASS TWO PASS FOUR PASS

A .......... Hot fluid to be cooled

B ......................... Cooled fluid

C .................. Cooling water in

D ................ Cooling water out

SP ......................... Single Pass

TP .............................Two Pass

FP ............................ Four Pass

AB Series

SAE Series

EAB Series

STS Series

SRAB Series

UAB Series

URAB Series

AA Series

STA Series

CS Series

STC Series

CK Series

SRCS Series

URCS Series

ONE PASS TWO PASS FOUR PASS

ABR Series

5

Copyright © 2001 American Industrial Heat Transfer, Inc.

SHELL & TUBE ACCESSORIES

APPLICATIONS & SPECS. ("Y" Strainers)

These strainers are engineered for water or steam, and are adaptable for many other uses. Cleaning is accomplished by simply removing a pipe

plug without disconnecting any piping. Or, if it is desirable to clean without interrupting service, a blow-off valve can be connected to the

clean-out opening. Note: Pumps, control valves, traps, or other equipment controlling the flow of liquids or gases require proper protection

with strainers for trouble free operation.

18 - Y BRASS STRAINERS

The 18 - Y strainer body is a red brass casting. Standard units have 50 mesh brass wire screens. Brazing connections are available on special

order instead of pipe threads.

20 - Y STRAINERS

The 20 - Y strainer has a heavy cast iron body with machined pipe thread inlet and outlet (National Pipe Thread N.P.T.). It contains a strainer

screen of 0.02" thick brass with 100, 1/16" perforations per inch.

C

D

A

Pipe Thread

INLET

OUTLET

E

Clean-out

Opening

Pipe Threa

d

B

MODEL

SIZE

A

(NPT)

DIMENSIONS (Inches)

WT.

(lbs.)

BCD

E

(NPT)

18 - Y

0.38"

0.50"

0.75"

1.00"

2.50"

2.50"

3.50"

3.50"

2.63"

2.63"

3.75"

3.75"

2.00"

2.00"

2.75"

2.75"

0.25"

0.25"

0.50"

0.50"

0.75

0.75

1.75

1.75

20 - Y

0.50"

0.75"

1.00"

1.25"

1.50"

2.00"

4.00"

4.00"

4.75"

6.00"

6.00"

8.13"

3.25"

3.25"

4.38"

5.13"

5.13"

6.38"

2.50"

2.50"

3.38"

3.88"

3.88"

4.63"

0.38"

0.38"

0.75"

0.75"

0.75"

0.75"

1.75

1.75

4.00

4.75

4.75

13.00

PRESSURE RATINGS, ALL MODELS: 125lbs. per Sq.In.

"Y" STRAINER (for Shell & Tube Heat Exchangers And Air/Oil Coolers)

THERMOSTATIC MODULATING WATER VALVE WITH BULB WELL ASSEMBLY

(for Shell & Tube Heat Exchangers And Air/Oil Coolers)

SPECIFICATIONS

Sizes 0.375", 0.50", 0.75", 1.00", 1.25" FPT

Fluid Pressure 125psi (max.)

Standard Temperature 40° - 100° F., 60° - 140° F., 100° - 175° F., 125° - 200° F.,

140° - 240° F., 200° - 275°F.

Body Brass alloy casting

Valve Parts Brass alloy

Standard Capillary Length 6’ & 20’ foot

Standard Bulbs For 3/8" & 1/2" valve sizes: 5/8" x 6 with 3/4" union

connections. For 3/4" & 1" valve sizes: 5/8" x 8-1/4"

with 3/4" union connections.

Stainless steel construction available.

Standard Bulb Mounting 3/4" NPT

Seat Disk Buna-N-replaceable

Seat Bead Stainless Steel - replaceable

Water Valve

Durable Bronze

Two-ply Bellows

(inside)

Armor-plated

Double Braided

Copper Capillary

Body and

Valve Parts

Are Special

Brass Alloy

Adjusting Cap

For Better

Temperature

Control

Copper

Alloy Bulb

APPLICATION INFORMATION

• Built for machine tool and hydraulic applications.

• Adjustable temperature range.

• Response to temperature changes.

• Direct acting bellows for longer service.

Note: Please consult factory if a non-cataloged temperature is required.

The type 56-T valve gives smooth regulation of water and other fluids. It's designed for rugged application. For example: hydraulic power

packaging equipment, hydraulic presses, plastic molding equipment, and anywhere reliability in temperature control is demanded.

The type 56-T valve is a better designed product that won't leak or chatter. For dependability, every valve is factory tested three times in

different temperature baths. They are direct acting with sturdy walls, and the inner spring is zinc coated. The seat beads are stainless steel to

resist the erosive effects of wire drawing and provide durability for your needs. Additional features include mounting in any position, Buna-

N seat disc, and manual flushing.

6

Copyright © 2001 American Industrial Heat Transfer, Inc.

AIR COOLED GENERAL INSTALLATION & MAINTENANCE

Receiving:

a) Inspect unit for any shipping damage before uncrating. Indicate

all damages to the trucking firms' delivery person and mark it on

the receiving bill before accepting the freight. Make sure that the

core and fan are not damaged. Rotate the fan blade to make sure

that it moves freely. Since the warranty is based upon the unit date

code located on the model identification tag, removal or manipu-

lation of the identification tag will void the manufacturers war-

ranty.

b) When handling the heat exchanger, special care should be taken

to avoid damage to the core and fan. All units are shipped with

wood skids for easy forklift handling

c) Standard Enamel Coating: American Industrial provides its stan-

dard products with a normal base coat of oil base air cure enamel

paint. The enamel paint is applied as a temporary protective and

esthetic coating prior to shipment. While the standard enamel coat-

ing is durable, American Industrial does not warranty it as a long-

term finish coating. It is strongly suggested that a more durable

final coating be applied after installation or prior to long-term stor-

age in a corrosive environment to cover any accidental scratches,

enhance esthetics, and further prevent corrosion. It is the responsi-

bility of the customer to provide regular maintenance against chips,

scratches, etc... and regular touch up maintenance must be pro-

vided for long-term benefits and corrosion prevention.

d) Special Coatings: American Industrial offers as customer op-

tions, Air-Dry Epoxy, and Heresite (Air-Dry Phenolic) coatings at

additional cost. American Industrial offers special coatings upon

request, however American Industrial does not warranty coatings

to be a permanent solution for any equipment against corrosion. It

is the responsibility of the customer to provide regular maintenance

against chips, scratches, etc... and regular touch up maintenance

must be provided for long-term benefits and corrosion prevention.

Installation:

a) American Industrial recommends that the equipment supplied

should be installed by qualified personnel who have solid under-

standing of system design, pressure and temperature ratings, and

piping assembly. Verify the service conditions of the system prior

to applying any air cooled heat exchanger series cooler. If the sys-

tem pressure or temperature does not fall within the parameters on

model rating tag located on the heat exchanger, contact our factory

prior to installation or operation.

b) In order for the heat exchanger to properly function, installation

should be made with minimum airflow obstruction distance of not

less than twenty (20) inches on both fan intake and exiting side of

the heat exchanger.

c) Process piping should beinstalled as indicated on the model dia-

gram, with the process flow entering into the INLET port and exit-

ing out the OUTLET port (see illustrations pages 9-10). Flexible

hose or non rigid plumbing can be used to reduce the risk of failure

due to thermal expansion of the core or hydraulic vibration. We

suggest that preventative filtration should be located ahead of the

cooler to catch any scale or sludge for the system before it enters

the cooler.

For hydraulic oil coolers is it suggested that a three-way thermal

bypass valve or a direct acting low-pressure (30psi or 60psi) relief

valve be installed at the inlet to the cooler to protect it in cold weather

environments.

d) Flow line sizes should be sized to handle the appropriate flow to

meet the system pressure drop requirements. If the nozzle size of

the heat exchanger is smaller than the process line size an increased

pressure differential at the heat exchanger may occur.

e) A brazed construction coil does not allow internal tube access. A

serviceable core

®

will allow full accessibility to the internal tubes

for cleaning and maintenance.

g) Electric motors should be connected only to supply source of

the same characteristics as indicated on the electric motor infor-

mation plate. Prior to starting, verify that the motor and fan spin

freely without obstruction. Check carefully that the fan turns in the

correct rotation direction (normally counter clockwise) from the

motor side (fan direction arrow). Failure to operate the fan in the

proper direction could reduce performance or cause serious dam-

age to the heat exchanger or other components. Fan blades should

be rechecked for tightness after the first 100 hours of operation.

h) It is important to apply the catalog recommended flow rate for

the hydraulic motor that corresponds with the specific model be-

ing used. A case drain is required for hydraulic motor installation.

Failure to connect case drain can result in motor failure. The proper

flow rate and direction to the hydraulic motor are critical to ensure

fan direction and RPM. Exceeding the recommended RPM could

result in fan failure and cause severe damage to the heat exchanger.

See fan rotation (pages 9-10)

Maintenance

Regular maintenance intervals based upon the surrounding and op-

erational conditions should be maintained to verify equipment per-

formance and to prevent premature component failure. Since some

of the components such as, motors, fans, load adapters, etc... are

not manufactured by American Industrial, maintenance require-

ments provided by the manufacture must be followed.

a) Inspect the entire heat exchanger and motor/fan assembly for

loosened bolts, loose connections, broken components, rust spots,

corrosion, fin/coil clogging, or external leakage. Make immediate

repairs to all affected areas prior to restarting and operating the

heat exchanger or its components.

b) Heat exchangers operating in oily or dusty environments will

often need to have the coil cooling fins cleaned. Oily or clogged

fins should be cleaned by carefully brushing the fins and tubes

with water or a non-aggressive degreasing agent mixture (Note:

Cleaning agents that are not compatible with copper, brass, alumi-

num, steel or stainless steel should not be used). A compressed air

or a water stream can be used to dislodge dirt and clean the coil

further. Any external dirt or oil on the electric motor and fan as-

sembly should be removed. Caution: Be sure to disconnect the

electric motor from its power source prior to doing any mainte-

nance.

c) In most cases it is not necessary to internally flush the coil. In

circumstances where the coil has become plugged or has a sub-

stantial buildup of material, flushing the coil with water or a sol-

vent may be done. Flushing solvents should be non-aggressive suit-

7

Copyright © 2001 American Industrial Heat Transfer, Inc.

AIR COOLED GENERAL INSTALLATION & MAINTENANCE

able for the materials of construction. Serviceable Core® models

can be disassembled and inspected or cleaned if required.

d) Most low horsepower electric motors do not require any addi-

tional lubrication. However, larger motors must be lubricated with

good quality grease as specified by the manufacture at least once

every 6-9 months or as directed by the manufacture. T.E.F.C. air

ventilation slots should be inspected and cleaned regularly to pre-

vent clogging and starving the motor of cooling air. To maintain

the electric motor properly see the manufactures requirements and

specifications.

e) Fan blades should be cleaned and inspected for tightness during

the regular maintenance schedule when handling a fan blade care

must be given to avoid bending or striking any of the blades. Fan

blades are factory balanced and will not operate properly if dam-

aged or unbalanced. Damaged fan blades can cause excessive vi-

bration and severe damage to the heat exchanger or drive motor.

Replace any damaged fan with an American industrial suggested

replacement.

f) Air cooled exchanger cabinets are constructed using 7ga. through

18ga. steel that may be bent back into position if damaged. Parts

that are not repairable can be purchased through American Indus-

trial.

g) Coil fins that become flattened can be combed back into posi-

tion. This process may require removal of the coil from the cabi-

net.

Brazed Core Maintenance

It is not advisable to attempt repairs to brazed joints of a brazed

construction coil unless it will be done by an expert in silver solder

brazing. Brazed coils are heated uniformly during the original manu-

facturing process to prevent weak zones from occurring. Uncon-

trolled reheating of the coil may result in weakening of the tube

joints surrounding the repair area. In many instances brazed units

that are repaired will not hold up as well to the rigors of the system

as will a new coil. American Industrial will not warranty or be

responsible for any repairs done by unauthorized sources. Manipu-

lation in any way other than normal application will void the manu-

factures warranty.

Serviceable Core

®

Maintenance

Units containing a Serviceable Core

®

have bolted manifold covers

that can be removed for cleaning or repair purposes. Most AOCH

or AOCS cores manufactured after January 1, 1998 are Service-

able Cores

®

.

Servicing Sequence

American Industrial has gone to great lengths to provide compo-

nents that are repairable. If the heat exchanger core requires inter-

nal cleaning or attention the following steps will explain what must

be done to access the internal tubes. Be sure to order gasket kits or

repair parts prior to removal and disassembly to minimize down

time.

a) To clean the internal tubes first remove all connection plumbing

from the unit.

b) Be sure the unit is drained of all water etc...

c) Place the heat exchanger in an area that it can be accessed from

all sides. Remove the core from the cabinet if required (AOCH,

AOCS).

d) Mark the cover

➀ and tube-sheet ➂ for both covers so that

they can be replaced into the same position when finished.

Re-

move the manifold cover bolts

➁

and hardware and place them

into a secure place.

e) The manifold covers are tightly compressed and may need some

prying to separate them from the gasket

≈

, physically remove the

cover assemblies

➀

from both sides.

f) The tubes

√

and turbulators

➄

are now accessible for cleaning.

Note: turbulators are installed on AOCH & AOCS cores only. If

you need to remove the turbulator that runs through the tubing, it

will be necessary to first squeeze the flattened end of the protrud-

ing turbulator

➄

, so that on end will fit through the tube. From the

opposite end pull the turbulator

➄

out. You may need to use pliers

to grip and pull the turbulators

➄

out, especially if there is debris

lodged inside. As the turbulators

➄

come out, most of the dirt will

too, so be prepared. It is suggested that gloves be worn when han-

dling the turbulators

➄

as they may be sharp.

We suggest a mild water-soluble degreaser be used with a brush.

Tubing I.D. is .325 a plastic bristle brush on a rod will work best

for cleaning the tubes

√

. Steel brushes should be avoided since the

steel is harder than the copper tubing and may heavily score the

tubes

√

if used.

g) If there are any leaking tubes

√

you may plug them by carefully

forcing a soft metal plug into the hole and tapping it tight. You may

in some cases weld the leaking tube shut however, care should be

taken since excessive heat may cause surrounding tube joints to

loosen and leak.

h) When finished cleaning or repairing, be sure to replace ALL of

the turbulators

➄

back into any open tubes

√

. When the turbulators

➄

protrude from the opposite end flatten them again so they are

tight and cannot be removed.

i) When finished reattach the manifold covers

➀

in the same posi-

tion they were removed, using new gaskets

≈

, bolts

➁

, and hard-

ware. We suggest using a torque wrench to final tighten the bolts

➁

. For 5/16" bolts 22-23 ft-lbs, for 3/8" bolts to 38-42 ft-lbs. Since

bolts and hardware can physically fatigue during application we

suggest new bolt kits be used when reassembling.

1

2

3

4

6

5

8

Copyright © 2001 American Industrial Heat Transfer, Inc.

UNION

FILTER

UNION

F

a

n

r

o

t

a

t

i

o

n

UNION

FILTER

CAPPED

F

a

n

r

o

t

a

t

i

o

n

AIR COOLED HEAT EXCHANGER PIPING HOOK-UP

AOCS - 1005

through

AOCS - 3015

AOCS - 201

through

AOCS - 603

ONE PASS TWO PASS

ONE PASS TWO PASS

UNION

CAPPED

FILTER

F

a

n

r

o

t

a

t

i

o

n

UNION

FILTER

UNION

F

a

n

r

o

t

a

t

i

o

n

Return Line

Relief Valve

Return Line

Filter

Heat

Exchanger

TYPICAL HYDRAULIC CIRCUIT

with air cooled heat exchanger

9

Copyright © 2001 American Industrial Heat Transfer, Inc.

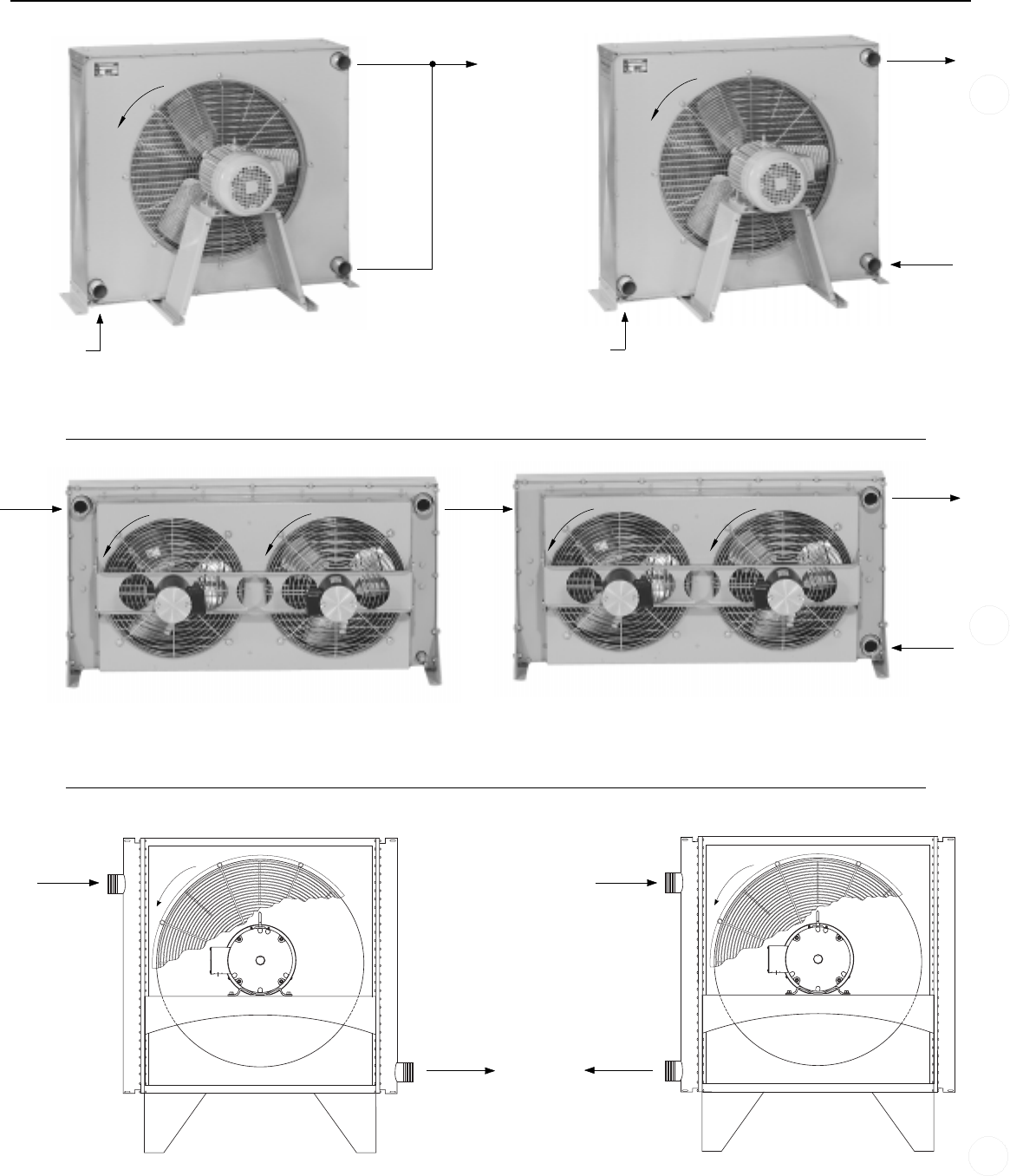

AIR COOLED HEAT EXCHANGERS PIPING HOOK-UP

AC, ACF & AOCH Series

ONE PASS

TWO PASS

ACA Series

EOC Series

ONE PASS TWO PASS

ONE PASS

F

a

n

r

o

t

a

t

i

o

n

TWO PASS

F

a

n

r

o

t

a

t

i

o

n

INLET

OUTLET

F

a

n

r

o

t

a

t

i

o

n

F

a

n

r

o

t

a

t

i

o

n

INLET

OUTLET

INLET

F

a

n

r

o

t

a

t

i

o

n

F

a

n

r

o

t

a

t

i

o

n

INLET

OUTLET

F

a

n

r

o

t

a

t

i

o

n

OUTLET

OUTLET

INLET

INLET

CAPPED

F

a

n

r

o

t

a

t

i

o

n

OUTLET

10

Copyright © 2001 American Industrial Heat Transfer, Inc.

LP Series

OUT

IN

IN or OUT

IN or OUT

AOMF

BM Series

Adjustable

brackets

OUT

IN

IN or OUT

IN or OUT

F

a

n

r

o

t

a

t

i

o

n

IN or OUT

IN or OUT

OUT

IN

AOM & AOMR Series

T

WO

P

ASS

S

INGLE

P

ASS

Adjustable

brackets

OUT

IN

IN or OUT

IN or OUT

AIR COOLED HEAT EXCHANGER PIPING HOOK-UP

OUT

IN

IN

OUT

IN

IN

OUT

OUT

11

Copyright © 2001 American Industrial Heat Transfer, Inc.

Insulation of boiler

or storage tank

Capillary

tubing

Tube Clip &

rubber gromet

1/2"-14 external

threads on spud

Wall or boiler or

storage tank

Immersion

Wall

Sensing Bulb

Spud screws into tapping

(reducer fitting may be

necessary to adapt spud

to tapping)

Sensing Bulb

Composition Disc

(slotted)

Packing Nut

Screws into tapping

in boiler or tank

Slotted brass washers

assembled in pairs

1/2" Capillary

compression

fitting

1/2"-14 External

threads on spud

Capillary

Tubing

ELECTRICAL TEMPERATURE CONTROLLER WITH BULB WELL ASSEMBLY (for Air/Oil Coolers)

SPECIFICATIONS:

A) Material: Copper

B) Power Limits:

1)

For three phase motor operation, use only with a magnetic starter, 125 VA

max. (VA =volts x amps)

2)For pilot duty, 125 VA max.

3)For direct connection to motor:

120v AC/8.0 amps max 230v AC/5.1 amps max

277v AC/4.2 amps max 460v AC/2.0 amps max

4)Temperature operating range: 55°F to 175°F.

APPLICATIONS (Temperature Controller)

The TC511 temperature controllers are designed to control the tempera-

ture of air or liquids in ducts, pipes, tanks, and boilers. Typical uses include

control of dampers and valves in heating, cooling, or heating-cooling sys-

tems. The TC511 has 1 spdt switch. It makes or breaks a circuit on a change

in temperature at the sensing bulb. Fast response models with adjustable

differential are available for duct installation. They respond approximately 4

times faster than standard models.

INSTALLATION

When installing this product:

1. Read instructions carefully. Failure to follow the instructions could

damage the product or cause a hazardous condition.

2. Check the ratings given in the instructions and on the product to make

sure the product is suitable for your application.

3. Installer must be a trained, experienced service technician.

4. After installation is complete, check out product operation as provided

in the instructions.

LOCATION AND MOUNTING.

The controller may be installed in any convenient position. Mount it

with 3 screws through the slotted holes in the back of the case. Be sure to

consider the length of the capillary before mounting the controller.

Install the sensing element where it is exposed to the average tempera-

ture of the controlled medium. The sensing bulb may be directly im-

mersed or mounted in a well. Fast response models must use the capillary

holder furnished with the device. The remote sensing bulb of standard

models should be held in place with a capillary holder, immersion well, or

compression fitting. Sharp bends or kinks in the capillary tubing affect the

efficiency of the controller and must be avoided. Excess capillary should

be carefully coiled and left directly beneath the controller.

NOTE: When pressure fittings are used in areas of vibration (such

as pipe lines) the bulb must be adequately supported.

OPERATION

As the temperature of the controlled medium falls below

the set point less differential, the TC511 switch makes

terminal R to B and energizes a normally close

solenoid valve to provide heat. In cooling applica-

tions, the TC511 makes terminal R to W as

the temperature rises above the set point,

energizing cooling equipment.

0.20

2.13

2.25

2.44

2.63

1.22

0.38

0.94

ø0.88 Knockout

Both ends

2.00

ø0.22 (3x)

ø0.37 (3x)

4.19

0.69

5.63

1.75

1.94

ELECTRICAL RATINGS:

TC511 models with adjustable differential:

TC511 models with fixed differential -125 VA at 120/208/240/

277 Vac.

MAXIMUM BULB PRESSURE: 50 psi (344.7 kPa) for direct

immersions.

AIR COOLED ACCESSORIES

12

Copyright © 2001 American Industrial Heat Transfer, Inc.

STANDARD TERMS AND CONDITIONS OF SALE (1/3)

All sales by American Industrial Heat Transfer Inc. ("Seller") to the party to whom a

Seller's Acknowledgment is addressed ("Purchaser") are subject to the following terms

and conditions in addition to the terms and conditions contained in any

acknowledgement or sales order confirming your order (“Seller’s Acknowledgement”).

Where terms of any such Seller’s Acknowledgement conflict with the following terms

and conditions, the terms and conditions of Seller’s Acknowledgement shall control.

These Terms and Conditions shall apply to all transactions between Seller and

Purchaser unless superseded by new Terms and Conditions delivered by Seller or by

the express terms and conditions contained in Seller's Acknowledgment.

Acceptance. All purchase orders are accepted by Seller at its General Offices in Zion,

Illinois. Seller's acceptance of any purchase order it receives is expressly limited to the

exact terms contained here and in this Seller's Acknowledgment. Additional or

different terms contained in Purchaser's offer or any attempt by Purchaser to vary any

of the terms here and in Seller's Acknowledgment shall be rejected but such proposal

shall not operate as a rejection of Purchaser's offer unless such variances are in the

terms of the description, quantity, price or delivery schedule of the goods or services to

be provided hereunder, in which case such additional or different terms shall be

deemed material and such offer shall be deemed accepted without said additional or

different terms or attempted variations. Acceptance by Seller of any purchase order

containing terms additional to or different from the terms contained in this Seller's

Acknowledgment or containing modifications of the terms contained here and in

Seller’s Acknowledgment shall not be deemed as assent to those additional, different or

modified terms. Purchaser's receipt of Seller's Acknowledgment without prompt

written objection thereto, or Purchaser's acceptance of all or any part of the goods or

services ordered from Seller, shall constitute assent by Purchaser to the terms

contained here and in Seller's Acknowledgment. If this Seller's Acknowledgment shall

be deemed an offer by Seller to sell goods or services to Purchaser, such offer is

expressly limited to the exact terms contained herein. The dispatch of a purchase order

by Purchaser shall then constitute Purchaser's acceptance of these Standard Terms and

Conditions of Sale and Seller's Acknowledgment. If this Seller's Acknowledgment is

deemed an offer as aforesaid, any proposal by Purchaser for additional or different

terms or any attempt by Purchaser to vary any of the terms of this Seller's Acknowledg-

ment in Purchaser's purchase order is hereby objected to and rejected; provided,

however, that any such proposal by Purchaser shall not operate as a rejection of Seller's

offer unless it contains variances in the terms of the description, quantity, price or

delivery of the goods or services to be provided hereunder, in which case any such

proposal shall be deemed material, and this Seller's Acknowledgment shall be deemed

accepted without said additional or different terms or attempted variations.

Payment Terms. The full amount billed or contracted for is due and payable thirty (30)

days from delivery of the goods or performance of services. A finance charge

computed at the periodic rate of one and one-half percent (1.5%) per month (which is

an annual rate of eighteen percent (18%)) on the unpaid balance will be made on

accounts not paid when due, and Purchaser agrees to pay such charges and pay

attorneys' fees if action is brought to collect from Purchaser. Unless otherwise

specified, 100% of the price quoted for any tooling is to be paid with the placement of

the order to Seller. Samples submitted shall be deemed approved and accepted if

written notice of rejection is not received within thirty (30) days after date of

submittal. Purchaser agrees that Seller shall have a possessory lien on all tools and

other property of Purchaser which is in Seller's possession for the total amount owing

by Purchaser to Seller for all tooling and other work and for all parts, materials and

services of all kinds supplied or rendered by Seller to Purchaser, which lien shall be

enforceable in the manner provided in the Uniform Commercial Code.

Taxes. Any tax which the Seller may be required to pay or collect through assessment

or otherwise, under any existing or future law upon or with respect to the sale,

purchase, delivery, transportation, storage, processing, use or consumption of any

goods or services described herein, including, without limitation, taxes upon or

measured by receipt from sales or services (but excluding taxes based upon the income

of Seller), shall be for the account of Purchaser and be added to the price of such goods

or services. Purchaser shall promptly pay the amount thereof to Seller upon demand

but may in lieu of such payment, furnish to Seller evidence of the issuance of tax

exemption certificates acceptable to the appropriate taxing authorities.

Prices. Except as otherwise provided, all price quotations are valid for thirty (30) days.

Prices are based on costs prevailing on the date of quotation and, therefore, are subject

to change at any time to reflect increased costs. Prices are quoted on samples,

blueprints, or drawings on hand, and any modification thereof subjects this quotation to

adjustment. Quotations are is based on the continuous production of the quantity

specified, smaller runs subject to increase in price. If higher quantity level is desired

by Purchaser, Seller will render a quotation based upon the revised requirements set

forth by Purchaser.

Credit. All orders are subject to the approval of Seller's Credit Department, and Seller

may at any time refuse to make shipment or delivery if Purchaser fails to fulfill the

terms and conditions of payment or fails to provide security satisfactory to Seller's

Credit Department. Seller reserves right to refuse or cancel credit and require full

payment prior to shipment. If in Seller's opinion the financial condition of Purchaser

at any time does not justify continuation of production or shipment on the terms of

payment specified, Seller may require full or partial payment in advance or such

further assurance as Seller shall require to justify such continued production or

shipment.

Default in Payment and Bankruptcy of Purchaser. If Purchaser fails to make payments

on any agreement between Purchaser and Seller in accordance with Seller's terms,

Seller, in addition to any other remedies available to it, may, at its option, (a) defer

further shipments until such payments are made and satisfactory credit arrangements

are reestablished, (b) cancel the unshipped balance of any order or (c) take any other

action available under applicable law. In the event of any proceedings, voluntary or

involuntary, in bankruptcy or insolvency by or against Purchaser, the inability of

Purchaser to pay its debts as they become due, or in the event of the appointment, with

or without Purchaser's consent, of an assignee for the benefit of creditors or of a

receiver, then Seller shall be entitled, in its sole discretion, to cancel the unshipped

balance of any order without any liability.

Transportation Charges. All prices, quotations, shipments and deliveries by Seller are

F.O.B. Seller's plant and risk of loss passes to Purchaser once goods are tendered for

such delivery. All transportation and other charges including handling fees are for the

account of Purchaser, including any increase or decrease in such charges prior to

shipment.

Method of Shipment. Method and route of shipment is at Seller's discretion, unless

Purchaser supplies explicit instructions, which are subsequently accepted by Seller in

writing. Seller does not assume responsibility for any damage directly or indirectly

resulting from delays in delivery. When parts are broken or damaged in transit from

Seller to Purchaser, it is considered the responsibility of Purchaser to file a claim with

the carrier for said breakage or damage. If the method of shipment specified by

Purchaser is deemed by Seller to be unavailable or otherwise unsatisfactory, Seller

reserves right to use an alternate method or route or both whether or not at a higher

cost to Purchaser. Seller shall promptly notify Purchaser of any such change. The risk

of loss or damage to the goods shipped shall pass to the Purchaser when the goods are

delivered to the carrier for shipment and Purchaser shall be responsible for insuring

such goods thereafter.

Producing or Shipping Point. Seller reserves right to produce and ship all or any part

of the goods specified in any order from any of its plants or facilities.

Force Majeure. Seller shall not be liable for any delay in the performance of orders, or

in the delivery or shipment of goods, or for any damages suffered by Purchaser as a

result of such delay when such delay is occasioned by causes beyond Seller's control.

Such causes shall include but are not limited to an act of God or the public enemy, fire,

explosion, flood, unusually severe weather, drought, war, riots, sabotage, vandalism,

accident, embargo, government priority, government action or failure of the govern-

ment to act when action is required, requisition or allocation or other action of any

governmental authority, interruption of or delay in transportation, inadequacy or

shortage or failure of supply of materials or equipment, breakdowns, non-scheduled

shutdowns for repairs, plant accidents, labor shortage, strikes, labor trouble, or by

compliance with any order or request of the United States Government or any officer,

department, agency, instrumentality or committee thereof. It is understood and agreed

that economic conditions affecting the ability or desirability of the performance of this

agreement by either party shall not be deemed to constitute "force majeure" circum-

stances as contemplated by this paragraph. The Seller shall have the right to cancel the

entire agreement with Purchaser or any part thereof in the event of the happening of

any such cause beyond the Seller's control without any resulting liability.

Good Delivery. Shipments made by Seller within a reasonable time after the specified

date of delivery shall constitute a good delivery. No right of cancellation shall accrue

to Purchaser based on such a delivery.

Permissible Variations. Goods shipped by Seller shall be within the limits and sizes

published by Seller, subject, however, to Seller's right to ship overages or underages in

accordance with Seller's standard practices and goods shipped by Seller will be subject

to standard variations provided such variations are non-functional or are not material in

nature.

LIMITED WARRANTY. SELLER MAKES NO WARRANTIES EXPRESSED OR

STANDARD TERMS AND CONDITIONS OF SALE

April 1, 2000 Supersedes all prior "Standard Terms And Conditions Of Sale"

13

Copyright © 2001 American Industrial Heat Transfer, Inc.

STANDARD TERMS AND CONDITIONS OF SALE (2/3)

IMPLIED, INCLUDING BUT NOT BY WAY OF LIMITATION, ANY IMPLIED

WARRANTY OF MERCHANTABILITY AND ANY IMPLIED WARRANTY OF

FITNESS FOR A PARTICULAR PURPOSE, ON ANY ORDER EXCEPT THAT

SELLER WARRANTS TITLE TO ALL GOODS FURNISHED BY SELLER AND

EXCEPT THAT SELLER WARRANTS FOR A PERIOD OF ONE YEAR FROM THE

DATE MARK LOCATED ON THE SELLER'S IDENTIFICATION TAG THAT ALL

GOODS DESCRIBED ON SELLER'S ACKNOWLEDGMENT OF PURCHASER'S

PURCHASE ORDER WILL BE MANUFACTURED IN ACCORDANCE WITH THE

SPECIFICATIONS, IF ANY, SET FORTH IN SAID PURCHASE ORDER AND

EXPRESSLY ACCEPTED IN SELLER'S ACKNOWLEDGMENT SUBJECT TO

SELLER'S STANDARD MANUFACTURING VARIATIONS AND PRACTICES. IN

THE CASE OF COMPONENTS OR ACCESSORIES FURNISHED BY SUPPLIERS

TO SELLER, PURCHASER'S WARRANTY FROM SELLER SHALL BE LIMITED

TO THE WARRANTY OF THE COMPONENT OR ACCESSORY SUPPLIER. THE

FOREGOING WARRANTIES ARE THE SOLE AND EXCLUSIVE WARRANTIES

APPLICABLE TO THE GOODS DELIVERED, AND ALL OTHER WARRANTIES,

EXPRESS OR IMPLIED, INCLUDING WITHOUT LIMITATION ANY WAR-

RANTY OF MERCHANTABILITY, ARE HEREBY EXPRESSLY DISCLAIMED

AND NEGATED. WITHOUT LIMITING THE GENERALITY OF THE FOREGO-

ING, PURCHASER ACKNOWLEDGES THAT SELLER'S PRODUCTS ARE NOT

PACKAGED OR PROTECTED FOR LONG PERIODS OF STORAGE AND THUS

MAY CORRODE OR RUST OVER TIME.

Damaged Goods. If any goods should arrive at Purchaser's destination in a damaged

condition or should a shortage occur, Purchaser shall immediately report the damage or

shortage to the delivering carrier and to Seller. Any loss or shortage occasioned by

damage or otherwise occurring in transit will be for account of Purchaser. Allegedly

defective goods or parts are to be returned by Purchaser to a destination specified by

Seller, freight charges prepaid by Purchaser. All repairs and replacements are subject

to verification and inspection by Seller. Seller shall not be responsible for costs of de-

installation and re-installation of goods or parts returned.

Claims. Claims respecting the condition of goods, compliance with specifications or

any other matter affecting goods shipped to Purchaser must be made promptly and,

unless otherwise agreed to in writing by Seller, in no event later than twenty-one (21)

days after receipt of the goods by Purchaser. Purchaser shall set aside, protect and

hold such goods without further processing until Seller has an opportunity to inspect

and advise of the disposition, if any, to be made of such goods. In no event shall any

goods be returned, reworked or scrapped by Purchaser without the express written

authorization of Seller. If field service is rendered by the Seller at Purchaser's request

and the alleged defect is found not to be with the Seller's product, component or

accessory, the Purchaser shall pay for the time and expenses of the field representative.

Bills for service, labor or other expenses that have been incurred by the Purchaser,

their customer or agent, without approval or authorization by the Seller, will not be

accepted. Changes or repairs attempted or made in the field without Seller's written

authorization automatically void all warranties.

LIMITATION OF PURCHASER'S REMEDIES. PURCHASER'S REMEDIES WITH

RESPECT TO ANY CLAIM ARISING OUT OF ANY ORDER, ANY GOODS

DELIVERED PURSUANT TO ANY ORDER AND EXPRESSLY ACCEPTED IN

SELLER'S ACKNOWLEDGMENT, OR SELLER'S PERFORMANCE IN CONNEC-

TION WITH ANY ORDER, INCLUDING, WITHOUT LIMITATION, ANY CLAIM

ARISING OUT OF ANY RECALL, DEFECT OR ALLEGED DEFECT IN ANY

GOODS OR SERVICES FURNISHED BY SELLER, SHALL BE LIMITED

EXCLUSIVELY TO THE RIGHT OF REPAIR OR REPLACEMENT OF SUCH

GOODS OR SERVICES, AT SELLER'S OPTION. WITHOUT IN ANY WAY

LIMITING THE GENERALITY OF THE FOREGOING, IN NO EVENT SHALL

SELLER BE LIABLE FOR ANY CONSEQUENTIAL OR INCIDENTAL DAM-

AGES, INCLUDING, WITHOUT LIMITATION, ANY LOSS OF ANTICIPATED

PROFITS INCURRED BY PURCHASER WITH RESPECT TO ANY GOODS OR

SERVICES FURNISHED BY SELLER, OR ANY DAMAGES ARISING FROM

INJURIES TO PERSONS AS A RESULT OF PURCHASER'S OR A THIRD PARTY'S

NEGLIGENCE. SELLER'S WARRANTY DOES NOT COVER FAILURES

RESULTING FROM THE IMPROPER INSTALLATION, MOUNTING DESIGN OR

APPLICATION OR FROM CORROSION. THE PROVISIONS OF THIS PARA-

GRAPH ARE A MATERIAL TERM OF THIS TRANSACTION.

Warranty Procedures. If Purchaser experiences a problem with Sellers goods and

believes that it is covered by Seller's warranty, or Purchaser has equipment that needs

to be repaired or replaced, contact Seller through Purchaser's local distributor. The

basic information that Purchaser will need to begin the process is the complete

nameplate data. Products will not be accepted for return unless an RGA (Return Goods

Authorization) number has been assigned by Seller and the product for return or repair

is shipped prepaid. Products returned for warranty evaluation must be complete

(without missing components), and unaltered (not disassembled, manipulated cleaned

or the like). The product(s) must have the original model tag fully intact. Products

returned for warranty consideration are subject to a $100 minimum fee plus any

additional handling charges in the event that the reason for the return is not covered by

Seller's warranty. Additional handling fees are to cover the cost of failure analysis,

testing and the like. All handling charges will be waived for products that are subject

to a valid warranty claim. Products to be returned for warranty are to be shipped

prepaid via Seller assigned carrier.

Returns and Returns Procedures. In order to return a product for credit, test, or repair,

Purchaser must follow the procedures outlined in this paragraph and, in the case of

repairs, the immediately following paragraph. Failure to follow return procedures

could result in lost items, delays, additional service charges, warranty denial or refusal

of shipment. All items being returned to Seller must be accompanied with an RGA

(Return Goods Authorization) number for identification purposes. Products returned

without a clearly marked RGA number will not be processed. RGA numbers can be

obtained only through Seller. Products being returned for restock and credit must be

complete (without missing components), unused, and within one year of original

factory purchase. The products must have the original model tag fully intact. Returned

products must be free of dents, customer applied paint, rust, or any permanent

alterations of any type. Products shipped for restock are to be shipped prepaid. Heat

exchangers being returned for credit are subject to a 30% restocking charge. Other

items such as, without limitation, valves and temperature controls are subject to a 15%-

50% restocking charge to be determined by the products’ usage or salability.

Restocking charges are applied to cover the cost or the retest and refitting equipment to

new condition. Seller will issue credit only after a thorough inspection has been

performed. NO DEBITS WILL BE HONORED UNTIL AFTER RETURN INSPEC-

TION APPROVAL.

Repairs. Products being returned for repair, refit, test or similar matters must be

drained completely prior to shipment. Purchaser must clearly label the product with

information to identify the Purchaser and Seller's RGA number. Purchaser should also

include a note with instructions for service, failure, nature of problem and the fluids

that are used inside of the product. A base handling charge of $100 will be applied for

each product regardless of condition that it is in when returned for evaluation.

Products being returned for evaluation must be shipped prepaid. Quotations for repair,

test, cleaning, and similar matters will be issued shortly after return to Seller. All

products returned shall be considered abandoned by Purchaser and may be scrapped if

the Purchaser or shipper renders no disposition instructions after 45 days from

notification by written quotation. Seller does not warranty any repaired products under

any circumstances. Products repaired and the repairs are the sole responsibility of the

owner of the products. Products sent to Seller for evaluation will be returned, upon

request and at the owner’s expense.

Quality Assurance. Seller shall have no obligation to ensure that any goods or services

purchased from Seller meet any special quality assurance specifications and/or other

requirements unless such specifications and/or other requirements are set forth in

Purchaser's purchase order or separately provided in writing to Seller and, in either

case, expressly accepted in this Seller's Acknowledgment and Purchaser represents that

goods which it purchases from Seller will not be applied by Purchaser or resold by

Purchaser for application to, any critical end use, including, without limitation, use in

connection with or in any way related to the construction or operation of a nuclear

facility unless the appropriate specification and/or other requirement for such end use

is set forth in Purchaser's purchase order and is expressly accepted in a separate writing

by Seller. In the event that any such goods or any services supplied by Seller in

connection therewith are applied to a critical end use without the appropriate

specification and/or other requirement therefor having been set forth in Purchaser's

purchase order and expressly accepted in a separate writing by Seller, Purchaser shall

indemnify and hold Seller harmless against any and all damages or claims for damages

made by any person for any injury, fatal or nonfatal, to any person or for any damage

to the property of any person incident to or arising out of such application, including,

without limitation, any loss resulting from radioactive, toxic, explosive, or other

hazardous properties of source material, special nuclear material, or by-product

material as such terms are defined in the Atomic Energy Act of 1954 or any law

amendatory thereof or regulations adopted pursuant thereto. The Seller reserves the

right to improve its products through changes in design or material, as it may deem

desirable without being obligated to incorporate such changes in products of prior

manufacture.

Cancellation. Purchaser Orders cannot be cancelled without cause by Purchaser

without the express written consent of the Seller. Should Purchaser attempt to cancel

an order without cause, Purchaser shall reimburse Seller against all loss occasioned by

such cancellation, including loss of anticipatory profits and liability for commitments

made by Seller relating to the Purchase Order and shall purchase any existing

inventory and work in process which Seller has in its possession to fulfill Seller's

existing orders for Purchaser at the time of cancellation. As used herein, "cause" shall

mean a material breach of Seller's duties and obligations hereunder and the failure to

cure such breach after Purchaser notifies Seller of such breach and affords Seller a

reasonable time to cure same.

14

Copyright © 2001 American Industrial Heat Transfer, Inc.

Confidentiality and Publicity. Purchaser shall consider all information furnished by

Seller to be confidential and shall not disclose any such information to any person, firm

or corporation, other than Purchaser's or Seller's employees, subcontractors or

government inspectors, unless authorized to do so by Seller in writing. Purchaser shall

not disclose in any manner to third parties, including, without limitation to, advertis-

ing, or publishing concerns, Seller's identity or the identity of any subsidiaries or

affiliates of Seller. Unless otherwise agreed to in writing, no commercial, financial or

technical information disclosed in any manner or at any time by Purchaser to Seller

shall be deemed secret or confidential and Purchaser shall have no rights against Seller

with respect thereto except such rights as may exist under patent laws.

Tooling. If and to the extent any Purchase Order relates to the purchase of tools, jigs,

die fixtures, equipment, drawings and specifications (collectively, "tooling") or

specifically requires tooling for completion by Seller, then Seller shall at all times be

and remain the owner of such tooling and shall bear the risk of loss and be responsible

for insuring same. If any Purchase Order requires the development of such tooling,

then the price quoted by Seller is based on a minimum production of a specified

quantity of parts from such tooling and, in the event Purchaser does not ultimately

purchase such quantity of parts, an equitable adjustment in the purchase price for

products shall be made to reflect such lower quantity and Seller's unamortized cost of

the tooling so produced. Seller's price quotation is based upon estimated usage of

tooling but no representations or warranties are made by Seller that the tooling so built

will ultimately be capable of producing product in accordance with such anticipated

usage. Purchaser agrees to pay for changes in tooling made necessary by changes in

specifications accepted by Seller, such changes to be made at Purchaser's risk. Parts

produced from Purchaser's supplied tooling cannot be guarantied by Seller. Purchaser

provided tooling is not insured and Seller shall not be responsible or liable for any loss

or damage thereto or for any materials or equipment owned or furnished by Purchaser.

Purchaser shall be solely responsible for insuring such tooling and Purchaser waives

any claim or right of subrogation it may have against Seller arising out of Seller's

failure to insure such tooling. Seller reserves the right to charge Purchaser the

reasonable costs and expenses of refurbishing any tooling if so required by Seller to

fulfill any Purchase Order. When for a period of one (1) year no orders are received

for parts to be produced from tooling, Seller may notify Purchaser in writing at

Purchaser's last known address in Seller's files that tooling is no longer proprietary to

Purchaser and, with respect to Purchaser supplied tooling, such tooling shall become

Seller’s property or, at Seller’s option, Seller man return such tooling to Purchaser at

Purchaser’s expense.

Prototypes. If this Purchase Order relates to the production of a prototype by Seller for

or on behalf of Purchaser, (a) such prototypes will be manufactured in accordance with

Purchaser's specifications including material selection and (b) actual product produced

by Seller may vary from such prototype in a non-material and non-functional manner.

Seller's sole liability in the event it is unsuccessful in producing a prototype in

accordance with Purchaser's specifications shall be limited to the purchase price paid

by Purchaser with respect thereto. Purchaser shall be responsible for the cost of all

tooling necessary for the development of the prototype as provided in the paragraph

Captioned “Tooling” above.

Technical Assistance and Advice. Seller's warranty shall not be enlarged and no

obligation or liability shall arise out of Seller's rendering of technical assistance,

technical advice facilities, service or recommendations made by Seller in connection

with Purchaser's purchases of the goods hereunder. Said technical services, advice,

assistance or recommendations made by Seller or any representative of Seller

concerning any use or application of any goods furnished hereunder is believed to be

reliable, but SELLER MAKES NO WARRANTY, EXPRESS OR IMPLIED, AND

THE SAME ARE HEREBY EXPRESSLY DISCLAIMED as to the same and the

results to be obtained. Purchaser assumes all responsibility for loss or damage

resulting from the use of any such goods.

Indemnification. Purchaser agrees to indemnify, save harmless and defend Seller from

and against any and all liability for loss, damage or injury to person or property in any

manner arising out of or incident to the performance of any Seller's Acknowledgment

or other sale by Seller or its servants, employees, agents or representatives. Without

limiting the generality of the foregoing, Purchaser will indemnify and hold harmless

Seller, its officers, employees, agents, successors, assigns, customers and users of its

products from and against any and all losses, expenses, claims, suits and liabilities

(including incidental and consequential damages and court costs and attorneys fees)

arising as a result of any claim that the manufacture, use, sale or resale of goods

delivered by Seller in accordance with Purchaser's specifications or designs infringes

on any patent, utility model, industry design, copyright or other intellectual property

rights in any country. Without limiting the generality of the paragraph captioned

“LIMITATION OF PURCHASER’S REMEDIES” above, in the case of any claim of

infringement or the sale of products is enjoined, Seller shall have no obligation to

procure for Purchaser the right to continue using such products or to replace same with

equivalent non-infringing products or to modify the products so they become non-

STANDARD TERMS AND CONDITIONS OF SALE (3/3)

infringing.

Setoffs. Purchaser shall make no deduction or setoff for any claim arising out of or from

any transaction with Seller nor shall Purchaser take any discount, credit or allowance

without Seller's written consent.

Assignment. Purchaser shall not assign any order or any interest therein without the written

consent of Seller. Any such actual or attempted assignment without Seller's prior written

consent shall entitle Seller to cancel such order upon written notice to Purchaser.

Termination. Seller may terminate any order or any part thereof for any reason at Seller's

convenience upon written notice to Purchaser. Upon such termination, Purchaser agrees to

waive all claims for damages including, without limitation, any loss of anticipated profits,

and to accept as its sole remedy for termination the reasonable additional costs of obtaining

substitute goods of the same quantity and quality, provided that in no event shall such costs

exceed the price of the order or part thereof so terminated as stated on Seller's Acknowledg-

ment. Any claim for adjustment not asserted within sixty (60) days from the date of such

termination shall be deemed to have been waived by Purchaser.

Allocation of Risk. Purchaser acknowledges that these Standard Terms and Conditions of

Sale and Seller's Acknowledgment allocates risks with respect to goods and/or services sold

to Purchaser and this risk allocation is reflected in the prices to be paid by Purchaser for

said goods and/or services purchased hereunder. Purchaser warrants that it has read this

provision, understands it and is bound by its terms.

Packaging. Seller will use all reasonable means to comply with any packaging, loading or

bracing requirements specified in any order. Seller will charge for compliance with

Purchaser's special requirements in accordance with Seller's price list for extras in effect at

time of shipment. If no packaging, loading or bracing requirements are specified by

Purchaser, Seller shall comply with the minimum requirements customarily applied by

Seller to the method of transportation used for such goods.

Entire Agreement. These Standard Terms and Conditions of Sale and Seller’s Acknowledg-

ment and any other documents referred to on the face thereof constitute the entire

agreement between Seller and Purchaser.

Modification. No addition or modification of the terms and conditions of these Standard

Terms and Conditions of Sale and Seller’s Acknowledgment shall be binding on Seller

unless specifically agreed to by Seller in writing.

Waiver. Seller's failure to insist on performance of any of these Standard Terms and

Conditions of Sale and Seller's Acknowledgment or to exercise any right or privilege or

Seller's waiver of any breach hereunder shall not thereafter waive any other terms,

conditions, or privileges, whether of the same or similar type.

Governing Law. Seller and Purchaser's agreement shall be governed by and interpreted in

accordance with the laws of the State of Illinois of the United States of America.

Manufacture, shipment and delivery are subject to any prohibition, restriction, priority,

allocation, regulation or condition imposed by or on behalf of the United States of America

or any other governmental body with appropriate jurisdiction which may prevent or

interfere with fulfillment of any order.

Re-orders. Re-orders, if accepted by Seller, are considered as placed under the same terms

and conditions as Purchaser's previous order, when such orders are not placed pursuant to a

formal written proposal and acceptance.

Disclosure. Seller shall have the right to disclosure of the identity of Purchaser and the

nature of the work Seller is performing on Purchaser's behalf to Seller's customers and

prospective customers and in any promotional materials provided such disclosure does not

contain any confidential and proprietary information concerning Purchaser.

DISPUTES. SELLER AND PURCHASER AGREE TO SUBMIT ANY DISPUTES

REGARDING ANY ORDER, ANY GOODS DELIVERED PURSUANT TO ANY ORDER

AND EXPRESSLY ACCEPTED IN SELLER'S ACKNOWLEDGMENT, OR SELLER'S

PERFORMANCE IN CONNECTION WITH ANY ORDER, INCLUDING WITHOUT

LIMITATION SELLER'S LIMITED WARRANTY OBLIGATION, TO MEDIATION BY

AN INDEPENDENT MEDIATOR TO BE MUTUALLY AGREED UPON BY SELLER

AND PURCHASER. THE COST OF SUCH MEDIATION SHALL BE BORNE

EQUALLY BY SELLER AND PURCHASER. IN THE EVENT SUCH MEDIATION

DOES NOT RESOLVE THEIR DISPUTE, SELLER AND PURCHASER AGREE TO

SUBMIT SUCH DISPUTE TO AN INDEPENDENT ARBITRATOR, TO BE MUTUALLY

AGREED UPON BY SELLER AND PURCHASER OR, OTHERWISE, CHOSEN BY THE

MEDIATOR. SELLER AND PURCHASER AGREE THAT ALL MEDIATION AND

ARBITRATION SHALL BE CONDUCTED IN ZION, ILLINOIS. THE NON-PREVAIL-

ING PARTY AT THE ARBITRATION SHALL PAY THE PREVAILING PARTY'S

ATTORNEYS' FEES AND COSTS INCURRED IN PARTICIPATING IN THE ARBITRA-

TION.

15

Copyright © 2001 American Industrial Heat Transfer, Inc.

AOCH Series with screen & Serviceable Core

®

• Industrial high capacity air/oil heat exchanger available in 8

standard sizes with electric or hydraulic drive.

AC,ACHM & ACF Series

• Industrial air/oil heat exchanger available in 8 standard sizes with

electric or hydraulic drive.

ACA Series

• Heavy-duty Serviceable Core

®

air cooled air after-coolers for

compressor sizes up to 500 HP.

AVAILABLE PRODUCTS

URCS Series

• U-tube heat exchangers for steam services with removable tubes

bundle in copper, 316L SS, or 90/10 Cu Ni.

CS Series

• Heat exchangers in copper, 316L SS, or 90/10 Cu Ni.

EOC Series with electric motor & filter as an option

.

• Versatile industrial/mobile grade heat exchanger available with

optional filter, AC, DC, and hydraulic drives.

American Industrial Heat Transfer, Inc. 3905 Route 173 - Zion, IL 60099 Tel: (847) 731-1000

16

20

Copyright © 2004 American Industrial Heat Transfer, Inc.

tel: 1 (847) 731-10003905 Route 173 Zion, IL 60099 www.aihti.comfax: 1 (847) 731-1010

note: AIHTI reserves the right to make reasonable design changes without notice.

21

Copyright © 2004 American Industrial Heat Transfer, Inc.

tel: 1 (847) 731-10003905 Route 173 Zion, IL 60099 www.aihti.comfax: 1 (847) 731-1010

note: AIHTI reserves the right to make reasonable design changes without notice.

ACCESSORIES shell & tube heat exchangers

56T THERMOSTATIC MODULATING WATER VALVE WITH BULB WELL ASSEMBLY

(for Shell & Tube Heat Exchangers And Air/Oil Coolers)

SPECIFICATIONS

Sizes 0.375", 0.50", 0.75", 1.00", 1.25" FPT

Fluid Pressure 125psi (max.)

Standard Temperature 40° - 100° F., 60° - 140° F., 100° - 175° F., 125° - 200° F.,

140° - 240° F., 200° - 275°F.

Body Brass alloy casting

Valve Parts Brass alloy

Standard Capillary Length 6’ & 20’ foot

Standard Bulbs For 3/8" & 1/2" valve sizes: 5/8" x 6 with 3/4" union

connections. For 3/4" & 1" valve sizes: 5/8" x 8-1/4"

with 3/4" union connections.

Stainless steel construction available.

Standard Bulb Mounting 3/4" NPT

Seat Disk Buna-N-replaceable

Seat Bead Stainless Steel - replaceable

Length for 3/4" - 1 1/4"

9.5"

Length for 1/2" - 3/8"

5.5"

APPLICATION INFORMATION

• Built for rugged machine tool and hydraulic applications.

• Adjustable temperature range to meet your requirements.

• Quick response to temperature changes.

• Extra heavy-duty direct acting bellows for longer service.

Note: Please consult factory if a non-cataloged temperature is required.

Part Number

Description

Size NPT Temp. Range

310-1001 3/8” 60

O

F - 140

O

F

310-1004 1/2” 60

O

F - 140

O

F

310-1008 3/4” 60

O

F - 140

O

F

310-1014 1” 60

O

F - 140

O

F

310-1020 1-1/4” 60

O

F - 140

O

F

310-1046 1-1/2” 60

O

F - 140

O

F

310-1047 2” 60

O

F - 140

O

F

310-1025 3/8” 100

O

F - 175

O

F

310-1005 1/2” 100

O

F - 175

O

F

310-1010 3/4” 100

O

F - 175

O

F

310-1015 1” 100

O

F - 175

O

F

310-1026 1-1/4” 100

O

F - 175

O

F

Bulb Well

Part Number

Brass

Part Number