CONCRETE FIREPROOFINGCONCRETE FIREPROOFING

ANALYSIS, EVALUATION AND

REPAIR STRATEGIES

ANALYSIS, EVALUATION AND

REPAIR STRATEGIES

April 12

16 2010

April 12

16 2010

April

12

-

16

,

2010

League City, Texas, USA

April

12

-

16

,

2010

League City, Texas, USA

Picture Courtesy of Refinery Terminal Fire Company (RTFC)

Fireproofing PurposeFireproofing Purpose

Maintaining structural

stability and integrity of

steel members and

vessel/pipe supports for a

defined period of time

when exposed to a fire

Protection

Active

Passive

Active

Passive

Picture Courtesy of Refinery Terminal Fire Company (RTFC)

2

Fireproofing BasicsFireproofing Basics

Material

minimum

thickness

Restrict heat

transfer rate

Protected

element

Acceptable steel

core temperature at

the end of fire

exposure to avoid

collapse/buckling

3

Comparison of Typical ‘Hydrocarbon’ and

‘

Cellulose

’

Time

-

Temperature Curves

2500 1400

Hydrocarbon

Cellulose

Time

Temperature

Curves

2000

1000

1200

it (°F)

s

(°C)

Cellulose

Hydrocarbon

Within 4

1500

800

F

ahrenhe

e

s Celsiu

s

Within

4

minutes

1000

400

600

D

egrees

F

Degre

e

0

500

0

200

D

0

02040

60

80

100

120

0

Minutes

4

Effect Of Temperature On Strength Of

Structural Steel

100

Structural

Steel

80

rength

60

riginal St

50% reduction

@ 1000

°

F

40

c

ent of O

@

1000

F

20

Per

c

0

50 300 550 800 1050 1300 1550

Degrees Fahrenheit (°F)

5

Fire And Explosion Behavior

Resistance to thermal and erosive forces

Surface temperature of substrate

Non-combustible

Withstand effects of explosion and subsequent

drag pressures

Picture Courtesy of Refinery Terminal Fire Company (RTFC)

6

Pre-Fire Durability

Weather cycling and chemical tolerance

V

apor permeability and low porosity

Vibration resistance - compressive, tensile and

flexural strength

Hardness value and impact resistance

Abrasion and erosion resistance

Bonding strength

Bonding

strength

Wash-down resistance

7

Passive Fireproofing Materials

CEMENTITIOUS

Lightweight

D

¾ Heat absorbers

¾ Hard and durable

¾

Economic

D

ense

Epoxy

¾

Economic

¾ Easy to install and repair

¾ React under fire and emit

g

ases

INTUMESCENT

Epoxy

based

g

¾ Form a low density carbonaceous

char

FIBROUS

Boards

Blankets

¾ Can provide thermal insulation

¾ Absorb water

¾ Indoor applications

COMPOSITES

Blankets

Com

p

osite

¾ Sandwich of metallic cladding,

cementitious board and mineral

COMPOSITES

p

Panels

cementitious

board

,

and

mineral

or ceramic fibers

¾ Not economically feasible

8

Cementitious Concrete Materials

Made with Portland cement or modified fire-

resistant cements

Specific weights

y Dense concrete - 140 to 150 lb./ft

3

Li ht i ht t

25 t 80 lb /ft

3

y

Li

g

ht

we

i

g

ht

concre

t

e -

25

t

o

80

lb

.

/ft

3

Thermal conductivity tends to be inversely

proportional to specific weight

proportional

to

specific

weight

Capable of withstanding direct flame

impingement up to 2000

o

F (1100

o

C)

impingement

up

to

2000

F

(1100

C)

Alkaline passive film protects the embedded

steel

9

Intumescent Epoxy Coatings

Intumescent coatings react to flame or heat at

around 300

o

Fahrenheit (149

o

C) by expanding

i t thi k lti ll l i l ti bl k t Thi

i

n

t

o a

thi

c

k

mu

lti

ce

ll

u

l

ar

i

nsu

l

a

ti

ng

bl

an

k

e

t

.

Thi

s

intumescent carbonaceous foam sharply limits

the spread of flame and insulates the steel.

the

spread

of

flame

and

insulates

the

steel.

Washable, aesthetically pleasing, mark resistant

surface like traditional

p

aint

p

Provide protection from corrosion

Require expertise in application and controlled

Require

expertise

in

application

and

controlled

conditions

Com

p

arativel

y

hi

g

her cost to cementitious

pyg

materials

10

Fireproofing Rating

A function of:

Time and ease of evacuation

Fire hazard

p

osed b

y

substance

py

Fire suppression capabilities

2 inches (50 mm) of

cementitious products will

cementitious

products

will

provide a 2-hour rating

(

BS476 & ASTM E-119

)

(

)

11

Concrete Fireproofing In

Processing Units

Multilevel Equipment

Multilevel

Equipment

Structures

Pipe Racks

12

Fireproofing Deterioration

CorrosionCorrosion

Cracking

Risk Of Loss Of

Fi P t ti

Fi

re

P

ro

t

ec

ti

on

Efflorescence

Fire Damage

13

Embedded Structural Steel

Corrosion Exposed During

Fireproofing Inspection

Fireproofing

Inspection

Process

14

Rust Stains Emerging From

Fireproofing Indicating

Fireproofing

Indicating

Early Evidence Of Steel

Member Corrosion

Failed Fireproofing Due To

Embedded Structural Steel

Member Corrosion

15

Improperly Detailed

Improperly

Detailed

Cementitious

Fireproofing, Notice

No Mesh

Reinforcement

Reinforcement

16

Severely Corroded

Embedded Wire

Mesh And Corroding

Mesh

And

Corroding

Structural Steel

Member Flanges

Severel

y

y

Corroded

Embedded Wire

Mesh And

Corrodin

g

g

Structural Steel

Members &

Connections

17

Fireproofing Deterioration Fireproofing Deterioration

MechanismMechanism

Corrosion

Corrosion-

Induced

Corrosion

Products

Delamination

/

Spalling

Induced

Cracking

Structural Steel

Cementitious

Structural

Steel

Beam/Column

Fireproofing

Surface

Corrosion

Shrinkage

Crackin

g

Corrosion

Products

g

18

Fireproofing Deterioration

()

Fireproofing Deterioration

()

Mechanism

(

cont.

)

Mechanism

(

cont.

)

Structural Steel

Structural

Steel

Beam/Column

Preformed

Inor

g

anic Panel

g

Fireproofing

Open Areas Within The “Boxed”

St t l M b Fill With M i t

Corrosion

St

ruc

t

ura

l

M

em

b

er

Fill

s

With

M

o

i

s

t

ure

And Promotes Corrosion

Products

19

Prior Repair

Shrinkage Cracked

And Pipe Slide

And

Pipe

Slide

Shoe “Seized” By

Corrosion

20

Fireproofing Deterioration

()

Mechanism

(

cont.

)

PIPELINE

C i B ild

U

Structural Steel

Co

rr

os

i

o

n

C

orros

i

on

B

u

ild

-

U

p

Frozen Slide

Cementitious

Fireproofing

Co os o

Rotation

St t l St l

Fireproofing

St

ruc

t

ura

l

St

ee

l

Beam/Column

Rotation

21

Condition Survey And

Evaluation

Assess the condition of concrete

fireproofing

fireproofing

Evaluate causes of concrete/steel

distress

distress

Provide conceptual repair

recommendations

22

Need For Fireproofing

Safety

Possible structural collapse

Restoration

y

Possible

structural

collapse

y Reduced fire

protection/lower expected

performance

y Personnel at risk due to

falling debris

falling

debris

Insurance costs

Aesthetics of

Aesthetics

of

damaged/falling

fireproofing

fireproofing

23

Visual Inspection And Mapping

Note: Excavation at crack locationNote: Excavation at crack location

24

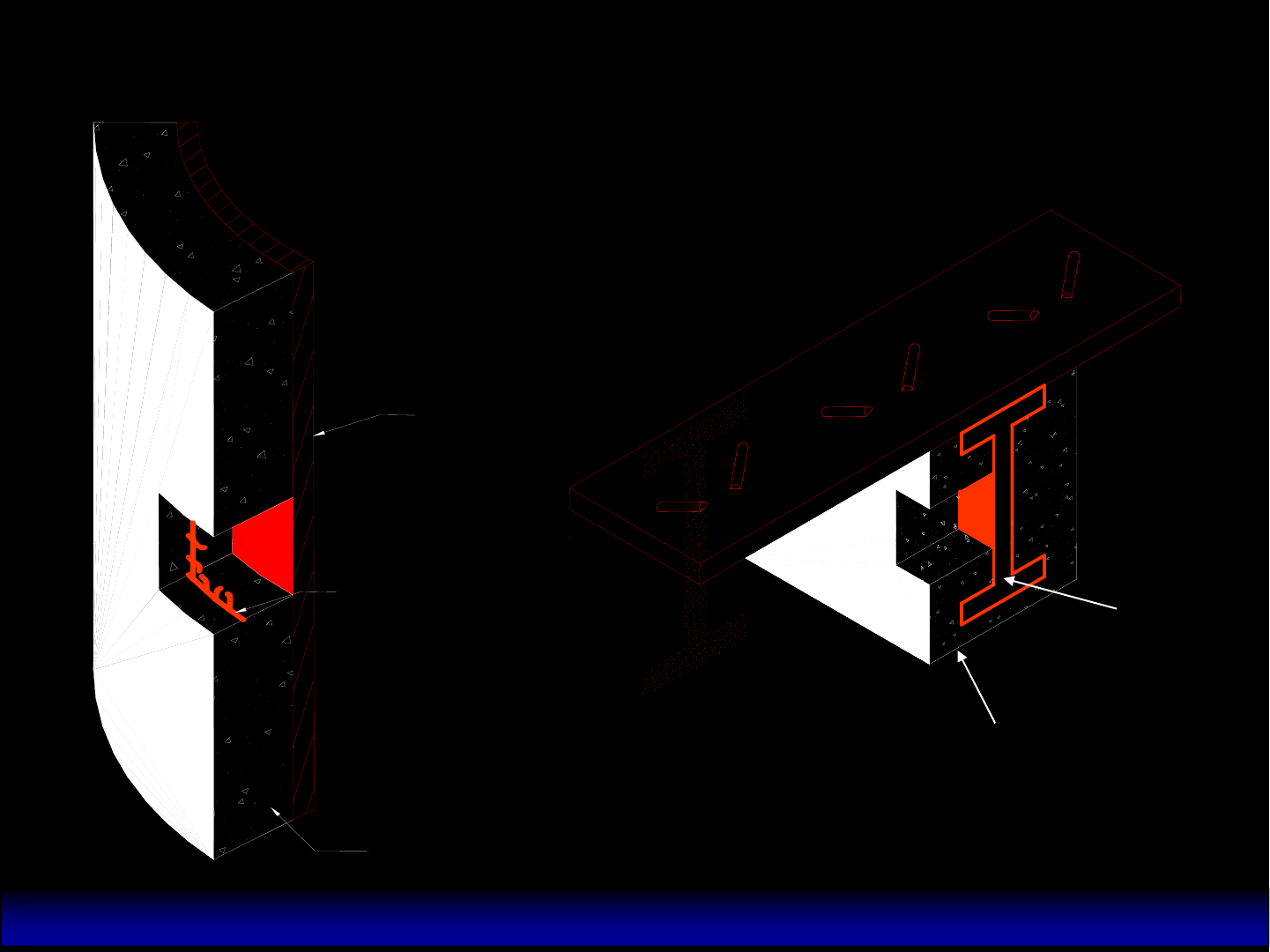

Excavation Geometry

St t l

St

ruc

t

ura

l

Steel

element

Reinforcing

wire mesh

Structural

Steel Beam

Fireproofing

Fireproofing

25

Ultrasonic Thickness

Measurements

Ultrasonic Thickness

Mt

Ultrasonic Thickness

Mt

M

e

t

er

Structural steel pipes,

bdb

M

e

t

er

Structural steel pipes,

bdb

we

b

s an

d

b

eams

flanges

Aidf

we

b

s an

d

b

eams

flanges

Aidf

A

ccess one s

id

e o

f

steel member

A

ccess one s

id

e o

f

steel member

26

Measurement Analysis

Wide Flange

Flange

Section

Wide

Flange

Shape

Flange

Thickness t

f

Section

Loss (%)

Theoretical

Measured

vs

If critical,

remedial actions

t

w

t

f

needed before...

27

Conceptual Fireproofing Repair

Assemble scaffolding for elevated regions

of distressed fireproofing

Assemble scaffolding for elevated regions

of distressed fireproofing

of

distressed

fireproofing

Remove deteriorated concrete fireproofing

and wire mesh avoiding damage to

of

distressed

fireproofing

Remove deteriorated concrete fireproofing

and wire mesh avoiding damage to

and

wire

mesh

avoiding

damage

to

structural steel members

Clean exposed embedded structural steel

and

wire

mesh

avoiding

damage

to

structural steel members

Clean exposed embedded structural steel

Clean

exposed

embedded

structural

steel

members of corrosion products

Inspect members and connections for

Clean

exposed

embedded

structural

steel

members of corrosion products

Inspect members and connections for

Inspect

members

and

connections

for

structural integrity

Coat exposed structural steel section

Inspect

members

and

connections

for

structural integrity

Coat exposed structural steel section

Coat

exposed

structural

steel

section

Coat

exposed

structural

steel

section

28

Fireproofing Repair (Cont.)

Install wire mesh

Abl t

ti ht it f k

Install wire mesh

Abl t

ti ht it f k

A

ssem

bl

e mor

t

ar-

ti

g

ht

cav

it

y

f

ormwor

k

Re-establish the cementitious fireproofing

ti b i “f d ” l t

A

ssem

bl

e mor

t

ar-

ti

g

ht

cav

it

y

f

ormwor

k

Re-establish the cementitious fireproofing

ti b i “f d ” l t

sec

ti

on

b

y us

i

ng

“f

orm an

d

pour

”

p

l

acemen

t

techniques

Rf kftiidd

sec

ti

on

b

y us

i

ng

“f

orm an

d

pour

”

p

l

acemen

t

techniques

Rf kftiidd

R

emove

f

ormwor

k

a

ft

er cur

i

ng per

i

o

d

an

d

surface grind cementitious repairs to match

original fireproofing surface contours

R

emove

f

ormwor

k

a

ft

er cur

i

ng per

i

o

d

an

d

surface grind cementitious repairs to match

original fireproofing surface contours

original

fireproofing

surface

contoursoriginal

fireproofing

surface

contours

29

Valuable Repair Aspects

Turnkey investigation

Attention to details

Bud

g

etin

g

ca

p

abilities

ggp

Corrosion protection to steel

Production rates

Production

rates

Adjustable crew size with qualified personnel

Hi h lit i t i l

Hi

g

h

qua

lit

y repa

i

r ma

t

er

i

a

l

s

Observe standard industry practices

30