updated March 2024 (Apply/Pay)

This study material is provided for free to the public. Page 1

FIRE DEPARTMENT ● CITY OF NEW YORK

CERTIFICATE OF FITNESS

STUDY MATERIAL

FOR

B-28 Supervision of Stationary Energy Storage Systems

(ESS)

W-28 Supervision of Mobile Energy Storage Systems

(ESS) (Citywide)

All applicants are required to apply and pay for an exam online before

arriving at the FDNY. It can take about 30 minutes to complete.

Simplified instructions for online application and payment can be found here:

http://www1.nyc.gov/assets/fdny/downloads/pdf/business/fdny-business-cof-

individuals-short.pdf

Create an Account and Log in to:

http://fires.fdnycloud.org/CitizenAccess

This book is provided to the public for free by the FDNY.

updated March 2024 (Apply/Pay)

This study material is provided for free to the public. Page 2

ALSO INCLUDED IN THIS BOOKLET YOU WILL FIND THE FOLLOWING:

NOTICE OF EXAMINATION (NOE)

© 1/2020 1

st

edition; 6/2022 2

nd

edition New York City Fire Department - All rights reserved ®

ATTENTION: The material presented in this booklet is highly comprehensive; it provides

information for applicants taking the above Certificate of Fitness examination. As the scope of

Energy Storage Systems is highly technical, FDNY recommends that applicants devote sufficient

amount of time and effort in preparation before taking the B-28/W-28 Certificate of Fitness

examination.

Specially designed Reference Material WILL BE provided to applicants during the exam. This

study material will NOT be provided to applicants during the exam. It is critical that applicant

understands the information presented in this booklet.

TO HELP YOU UNDERSTAND WHICH CERTIFICATE OF FITNESS YOU SHOULD APPLY FOR, PLEASE

NOTE THE FOLLOWING:

updated March 2024 (Apply/Pay)

This study material is provided for free to the public. Page 3

Contents

EXAM SPECIFIC INFORMATION FOR B-28/W-28 CERTIFICATE OF FITNESS .......................... 8

STUDY MATERIAL AND TEST DESCRIPTION .................................................................................................... 16

INTRODUCTION ................................................................................................................................................... 18

PURPOSE OF FIRE CODE Section 608 .......................................................................................................... 19

PURPOSE OF RULE 3 RCNY 608-01 ............................................................................................................ 19

PURPOSE OF THE STUDY MATERIAL ...................................................................................................... 19

DEFINITIONS ....................................................................................................................................................... 20

CHAPTER 1. CASE STUDIES .......................................................................................................................... 27

CHAPTER 2. STATIONARY ENERGY STORAGE SYSTEMS .......................................................................... 33

2.1 Five Types of Energy Storage Technologies ........................................................................................ 34

2.1.1 Lithium-ion (Li-ion) batteries ...................................................................................................... 35

2.1.2 Lithium Metal Polymer batteries ................................................................................................... 36

2.1.3 Flow batteries ................................................................................................................................ 36

2.1.4 Nickel cadmium batteries .............................................................................................................. 36

2.1.5 Nickel metal hydride (Ni-MH) batteries ....................................................................................... 37

2.1.6 Lead acid batteries ......................................................................................................................... 37

2.2 Multiple Layers of Stationary Energy storage Systems ........................................................................ 38

2.3 Different Battery Energy Storage Systems Benefits and Hazards ........................................................ 39

2.3.1 Benefits of different Battery Energy Storage Systems .................................................................. 39

2.3.2 Hazards of different Battery Energy Storage Systems .................................................................. 39

2.4 Battery Systems Size Thresholds (only applies to outdoor/rooftop stationary or mobile energy storage

systems) ............................................................................................................................................................. 41

2.5 Multiple Battery Systems ...................................................................................................................... 42

2.6 Mobile energy storage Systems............................................................................................................. 43

CHAPTER 3. PERMITS, ROLES AND RESPONSIBILITIES ........................................................................... 44

3.1 Permits................................................................................................................................................... 44

3.1.1 DOB work permit ........................................................................................................................... 44

3.1.2 FDNY permit .................................................................................................................................. 44

3.2 Obligations of Owner and Operator ...................................................................................................... 44

3.3 B-28/W-28 Certificate of Fitness Holder’s General Duties .................................................................. 45

3.3.1 Outdoor/mobile/rooftop systems ................................................................................................... 45

updated March 2024 (Apply/Pay)

This study material is provided for free to the public. Page 4

3.3.2 Indoor systems .............................................................................................................................. 45

3.4 Subject Matter Experts (SMEs)............................................................................................................. 46

3.5 ESMS monitoring facility staff ............................................................................................................. 48

3.6 Other possible related systems and the related license holders ............................................................. 48

CHAPTER 4. GENERAL DESIGN AND INSTALLATION REQUIREMENTS .................................................. 51

4.1 Listing and Full-scale testing standards ................................................................................................ 51

4.2 Equipment Approval (Certificate of Approval) .................................................................................... 51

4.3 Maximum Aggregate Rated Energy Capacity ....................................................................................... 51

4.3.1 Outdoor/rooftop/mobile systems ................................................................................................... 51

4.3.2 Indoor systems .............................................................................................................................. 51

4.3.3 Special requirements for Group R-3 occupancies: ........................................................................ 52

4.4 Installation Approval (Site Approval) ................................................................................................... 52

4.4.1 Outdoor/rooftop/mobile systems ................................................................................................... 52

4.4.2 Indoor systems .............................................................................................................................. 53

4.5 Location and Construction .................................................................................................................... 53

4.5.1 Outdoor/rooftop/mobile systems ................................................................................................... 53

1. Outdoor location (including rooftop when authorized) ......................................................................... 53

2. Fire Department access and Fire Protection System water supply........................................................ 53

3. Separation distances .............................................................................................................................. 53

4. Rooftop locations .................................................................................................................................. 54

5. Physical Protection ................................................................................................................................ 55

4.5.2 Indoor systems .............................................................................................................................. 56

4.6 Remote monitoring ................................................................................................................................ 56

4.7 Electrical components ........................................................................................................................... 56

4.7.1 Secondary stand-by power ............................................................................................................ 56

4.7.2 Disconnect switch and Lockout/Tagout Procedure ....................................................................... 56

4.7.3 Emergency shut down (e-stop) ...................................................................................................... 59

4.8 Special Requirements for the Battery Systems Installed in Group R-3 Occupancies ........................... 61

CHAPTER 5. ENCLOSURE DESIGN AND INSTALLATION REQUIREMENTS.............................................. 62

5.1 Enclosure designs for the outdoor systems ........................................................................................... 62

5.2 Fire Protection Systems ......................................................................................................................... 62

5.2.1 Outdoor/rooftop systems ............................................................................................................... 62

5.2.2 Indoor systems .............................................................................................................................. 65

updated March 2024 (Apply/Pay)

This study material is provided for free to the public. Page 5

5.3 Fire Detection Systems and Gas Detection Systems ............................................................................. 65

5.3.1 Outdoor/rooftop systems ............................................................................................................... 65

5.3.2 Indoor systems .............................................................................................................................. 66

5.3.3 Special requirements for the ESS systems in Group R-3 occupancies ......................................... 67

5.4 Exhaust ventilation system .................................................................................................................... 67

5.4.1 Outdoor/rooftop systems ............................................................................................................... 67

5.4.2 Indoor systems .............................................................................................................................. 68

5.5 Explosion mitigation ............................................................................................................................. 68

5.5.1 Outdoor/rooftop systems ............................................................................................................... 68

5.5.2 Indoor systems .............................................................................................................................. 69

5.6 Smoke/gas purge system ....................................................................................................................... 69

5.6.1 Outdoor/rooftop systems ............................................................................................................... 69

5.6.2 Indoor systems .............................................................................................................................. 70

CHAPTER 6. COMMISSIONING AND DECOMMISSIONING ......................................................................... 71

6.1 Commissioning ..................................................................................................................................... 71

6.2 Decommissioning .................................................................................................................................. 72

6.2.1 Decommissioning plan .................................................................................................................. 72

6.2.2 Decommissioning Process ............................................................................................................. 74

CHAPTER 7. OPERATION AND MAINTENANCE .................................................................................... 76

7.1 Remote Monitoring of Energy Storage Management System (ESMS) and Reporting ......................... 76

7.2 Central Station Monitoring of Fire Protection Systems ........................................................................ 78

7.3 Signage .................................................................................................................................................. 78

7.4 Maintenance .......................................................................................................................................... 80

7.4.1 Periodic inspection ........................................................................................................................ 81

7.4.2 Replacement components .............................................................................................................. 81

7.4.3 Combustible waste and vegetation ................................................................................................ 82

7.4.4 Storage of combustible materials .................................................................................................. 82

7.5 Requirements for Impairment Situation ................................................................................................ 82

7.5.1 ESMS does not transmit signal to the ESMS monitoring facility ................................................. 82

7.5.2 ESMS is out of service .................................................................................................................. 82

7.5.3 The required fire detection system (fire alarm system) or explosion mitigation is out of service 82

7.5.4 Any required fire protection system (e.g. standpipe system, sprinkler system) or manually-

operated purge system that serve the ESS is out of service .......................................................................... 83

updated March 2024 (Apply/Pay)

This study material is provided for free to the public. Page 6

CHAPTER 8. Fire Alarm System .................................................................................................................... 85

8.1 Introduction ........................................................................................................................................... 85

8.2 Fire Alarm Control Panel and Communication Systems ...................................................................... 86

8.2.1 Pre-signal systems with Event/Non-Event Mode (only applies to rooftop energy storage system

or indoor energy storage systems in assembly occupancies) ........................................................................ 86

8.2.2 Emergency voice/alarm communication systems (only applies to rooftop energy storage system

or indoor energy storage systems) ................................................................................................................. 87

8.2.3 Fire Command Center (only applies to rooftop energy storage system or indoor energy storage

systems) 87

8.3 Three Fire Alarm Control Panel Signals ............................................................................................... 88

8.4 Fire Alarm Signal is Generated ............................................................................................................. 89

8.4.1 Acknowledge switch or button ...................................................................................................... 89

8.4.2 Alarm silence switch or button ...................................................................................................... 89

8.4.3 System reset switch or button ........................................................................................................ 89

8.5 Initiating Devices .................................................................................................................................. 90

8.5.1 Smoke detectors ............................................................................................................................ 90

8.5.2 Heat detectors ................................................................................................................................ 91

8.5.3 Sprinkler waterflow alarm-initiating devices (only applies to the enclosure that protected by an

automatic sprinkler system) .......................................................................................................................... 92

8.5.4 Manually actuated alarm-initiating devices .................................................................................. 92

8.5.5 Flammable/combustible gas detectors ........................................................................................... 93

8.5.6 Types of devices and activations ................................................................................................... 93

8.6 Power Supplies for the Fire Alarm System ........................................................................................... 94

8.7 Audible and Visual Notification Devices .............................................................................................. 94

8.8 Central Station Contact Information, Central Station Transmitter and Fire Alarm System Off-Line .. 95

8.9 Periodic Inspection and Testing Requirements ..................................................................................... 96

8.9.1 Inspection frequencies ................................................................................................................... 96

8.9.2 Companies and individual certifications ....................................................................................... 96

8.10 Unnecessary and Unwarranted Alarms ................................................................................................. 97

CHAPTER 9. CAUSES OF BATTERY FAILURES AND EMERGENCY MANAGEMENT PLAN ......... 98

9.1 Root Causes of Energetic Cell and Battery Failures ............................................................................. 98

9.1.1 Thermal abuse ............................................................................................................................... 98

9.1.2 Mechanical abuse/damage ............................................................................................................. 98

9.1.3 Electrical abuse ............................................................................................................................. 99

updated March 2024 (Apply/Pay)

This study material is provided for free to the public. Page 7

9.1.4 Poor design and manufacturing defects......................................................................................... 99

9.1.5 Other possible causes for lead-acid batteries ................................................................................ 99

9.2 Emergency Management Plan ............................................................................................................. 100

CHAPTER 10. NOTIFICATIONS AND EMERGENCY RESPONSES .................................................... 102

10.1 Commissioning and Decommissioning Notification .......................................................................... 102

10.2 Remote monitoring and reporting ....................................................................................................... 103

10.3 Technical Assistance and Emergency Management ........................................................................... 103

10.3.1 Technical assistance .................................................................................................................... 103

10.3.2 Emergency Management ............................................................................................................. 103

10.4 Interaction with First Responders ....................................................................................................... 104

10.4.1 Incident Command System (ICS) ............................................................................................... 104

10.4.2 Information that may be required by the first responders ........................................................... 104

10.5 Post-Fire Consideration and Restoration to Service ............................................................................ 105

10.5.1 Site security ................................................................................................................................. 106

10.5.2 Emergency decommissioning ..................................................................................................... 106

10.5.3 Restoration to Service (re-commissioning) ................................................................................. 107

CHAPTER 11. RECORDKEEPING REQUIREMENTS ..................................................................................... 108

11.1 Recordkeeping ..................................................................................................................................... 108

11.2 Energy Storage System (ESS) Recordkeeping .................................................................................... 108

11.3 Fire Alarm Logbook ............................................................................................................................ 109

APPENDIX A: REFERENCE MATERIAL (This Part will be provided to you during the exam) ................... 113

Hazards of Different Battery Energy Storage Systems ............................................................................... 116

Benefits of different Battery Energy Storage Systems ................................................................................ 118

Stationary Energy storage system Size Thresholds ..................................................................................... 118

Ampere-Hour Conversion ........................................................................................................................... 118

Fire Alarm System Mandatory Visual Inspection Frequency ..................................................................... 119

APPENDIX B: Fire Code Section 608 ............................................................................................................... 120

APPENDIX C: Fire Department Rule Section 608-01 ....................................................................................... 130

APPENDIX D: INCIDENT COMMAND SYSTEM INCIDENT SEQUENCE................................................ 140

updated March 2024 (Apply/Pay)

This study material is provided for free to the public. Page 8

EXAM SPECIFIC INFORMATION FOR

B-28/W-28 CERTIFICATE OF FITNESS

Save time and submit application online!

Applicants who submitted and paid online for an exam before arriving at the

FDNY will not need to wait in line to enter the FDNY.

It can take about 30 minutes to complete. Completing application and paying

online will eliminate waiting outside in the long lines.

Simplified instructions for online application and payment can be found here:

http://www1.nyc.gov/assets/fdny/downloads/pdf/business/fdny-business-cof-individuals-short.pdf

Create an Account and Log in to:

https://fires.fdnycloud.org/CitizenAccess/SAML/NYCIDLogin.aspx

REQUIREMENTS FOR CERTIFICATE OF FITNESS APPLICATION

General requirements:

Review the General Notice of Exam:

https://www1.nyc.gov/assets/fdny/downloads/pdf/business/general-notice-of-exam-cof.pdf

Special requirements for B-28/W-28 Certificate of Fitness:

(1) B-28/W-28 COF applicants need to submit the Battery System Training Verification Letter.

Applicant must present an affidavit from the battery system owner, manufacturer or the

installer of the battery system stating that this applicant has been trained and is knowledgeable

with the battery system he/she will supervise. The sample of this verification letter is provided

on the following pages or the following link:

https://www1.nyc.gov/assets/fdny/downloads/pdf/business/b28-w28-verification-letter.pdf

(2) B-28/W-28 COF applicants need to submit the Employer Recommendation Letter.

Sample recommendation letter is provided on the following pages or the following link:

https://www1.nyc.gov/assets/fdny/downloads/pdf/business/b28-w28-sample-letter.pdf

(3) W-28 and B-28 COF holders can obtain W-27 COF without taking the W-27 exam but only

pay the $25 application fee.

(4) W-28 COF holder is only authorized to supervise the mobile battery system. W-28 COF is

citywide.

(5) B-28 COF is premises related, the B-28 COF authorizes the holder to supervise any indoor and

outdoor stationary battery system that is NOT designated as a mobile system.

updated March 2024 (Apply/Pay)

This study material is provided for free to the public. Page 9

Application fee (Cash is NO LONGER ACCEPTED):

Pay the $25 application fee online or in person by one of the following methods:

• Credit card (American Express, Discover, MasterCard, or Visa)

• Debit card (MasterCard or Visa)

• In person: Personal or company check or money order (made payable to the New York City Fire

Department)

A convenience fee of 2% will be applied to all credit card payments.

For fee waivers submit: (Only government employees who will use their COF for their work- related

responsibilities are eligible for fee waivers.)

• A letter requesting fee waiver on the Agency’s official letterhead stating applicant full name,

exam type and address of premises; AND

• Copy of identification card issued by the agency

REQUIREMENTS FOR ALTERNATIVE ISSUANCE PROCEDURE (AIP)

No AIP available. This certificate of fitness can only be obtained by passing the computer

exam at the FDNY Headquarters.

EXAM INFORMATION

The B-28/W-28 exam will consist of 75 multiple-choice questions, administered on a “touch screen”

computer monitor. It is a time-limited exam. A passing score of at least 70% is required in order to secure

a Certificate of Fitness.

Special material provided during the test:

The reference material in Appendix A will be provided when you take the test at Metro Tech. However,

the booklet will not be provided to you during the test.

Call (718) 999-1988 for additional information and forms.

Please always check for the latest revised booklet at FDNY website before you take the exam.

http://www1.nyc.gov/assets/fdny/downloads/pdf/business/cof-b28-w28-study-material.pdf

updated March 2024 (Apply/Pay)

This study material is provided for free to the public. Page 10

Exam site: FDNY Headquarters, 9 MetroTech Center, Brooklyn, NY. Enter through the

Flatbush Avenue entrance (between Myrtle Avenue and Tech Place).

RENEWAL REQUIREMENTS

General renewal requirements:

Review the General Notice of Exam:

https://www1.nyc.gov/assets/fdny/downloads/pdf/business/general-notice-of-exam-cof.pdf

Special renewal requirements.

B-28/W-28 Certificate of Fitness must be renewed every 3 YEAR. The renewal fee is $15. FDNY also

reserves the right to require the applicants to take a re-examination upon submission of renewal

applications.

You will receive a courtesy notice of renewal 90 days before the expiration date. However, it is your

responsibility to renew your Certificate. It is very important to renew your COF before it expires.

Renewals submitted 90 days (up to one year) after the expiration date will incur a $25 penalty in

updated March 2024 (Apply/Pay)

This study material is provided for free to the public. Page 11

addition to the renewal fee. Certificates expired over one year past expiration date will not be renewed.

New exams will be required.

The FDNY strongly recommends the B-28/W-28 COF holders to renew the COF on-line. To

learn the simplified on-line renewal:

https://www1.nyc.gov/assets/fdny/downloads/pdf/business/cof-simplified-renewal-short.pdf

QUESTIONS?

FDNY Business Support Team: For questions, call 311 and ask for the FDNY Customer Service

Center or send an email to [email protected].

updated March 2024 (Apply/Pay)

This study material is provided for free to the public. Page 12

Energy Storage System (ESS) Training Verification Letter

Please print or type the information below. This form must be NOTARIZED.

This verification letter is to verify that _________________ (Name of Applicant) has been trained in the

energy storage system that the applicant will supervise.

the owner of the battery system

I am

the manufacturer of the battery system

the installer of the battery system

I affirm that I have the comprehensive knowledge and required material to administer the training for

the applicant that listed in this letter.

The size of the energy storage system (ESS) is ______________ kWh and the type of the energy storage

system (ESS) is

(check the one that applies)

Lithium-ion

Flow

Nickel cadmium

Nickel metal hydride

Flooded (Vented) Lead acid

Valve-Regulated Lead Acid (VRLA)

Other: ____________________________________ (please specify)

The remote monitoring company of this energy storage system’s Energy Storage Management System

(ESMS) is ________________________ (company name) and its contact phone number is:

______________.

Section A

- Premises Verification

This system is a mobile energy storage system, list the addresses of all locations that are approved

by the FDNY (add another sheet if needed):

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

This system is a stationary storage battery system, the energy storage system located at:

______________________________________________________________________________

(address of the energy storage system, if it is on rooftop, it should also be specified)

updated March 2024 (Apply/Pay)

This study material is provided for free to the public. Page 13

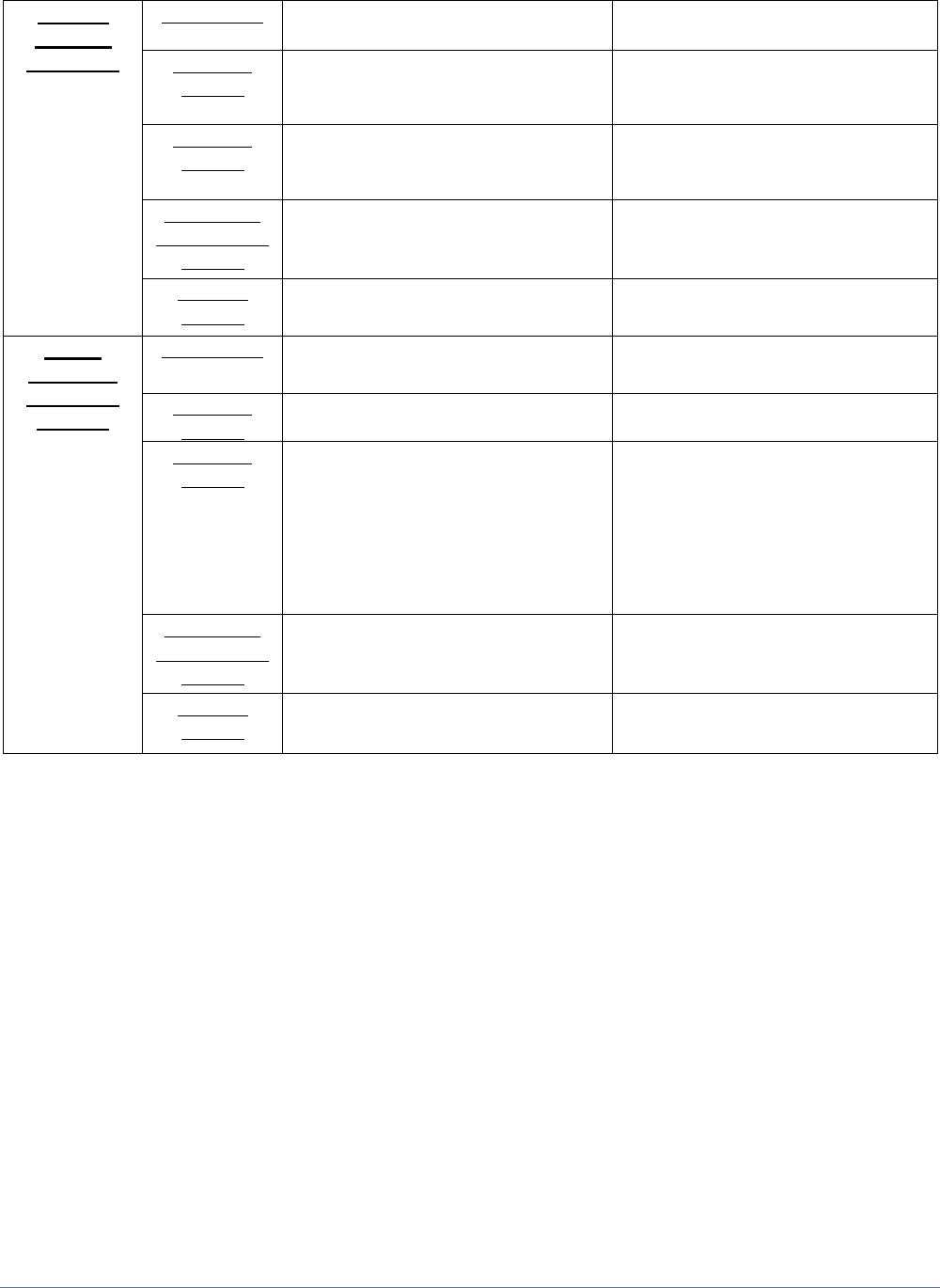

Section B - Energy Storage System (ESS) Training Verification

I, __________________________, hereby certify that the applicant has been trained and obtained the

following information related to the energy storage system that he/she will supervise. (All items below

must be marked “Yes” or “N/A” to proceed)

Information

The type, size of the battery systems

Yes

The possible hazards of the energy storage system

Yes

The area that the energy storage system serves and the

impact of shutting down the entire system

Yes

Safety Data Sheets (SDS) of the energy storage system

Yes

The Emergency Management Plan

Yes

Commissioning plan

Yes

Decommissioning plan (end-of-life decommissioning

plan and emergency decommissioning plan)

Yes

The type of fire extinguishing systems will be installed

and designed hold time (if applicable, refer to the section

5.1 of this booklet)

Yes

N/A, there is no fire extinguishing systems.

Procedures for safe shutdown, de-energizing, or isolation

of equipment and systems under emergency conditions

Yes

Procedure for notification in need of maintenance or

service

Yes

Procedure for notifications in case of fire, explosion,

release of liquids or vapors, damage to critical moving

parts, or other potentially dangerous conditions

Yes

Contact information of the ESMS monitoring facility and

the SMEs

Yes

The general function of the ESMS including how this

system monitors or manages the energy storage

performance and status of health, safe operation,

notifications, etc.

Yes

Standoff distances for electrical hazards and explosion

hazards

Yes

Procedures for annual inspection

Yes

The planned/actual location of:

Required signs

Yes

E-stops

Yes

Disconnect switches (i.e. “lock-out, tag-out”)

Yes

The vent and the manual activation

switch of the smoke/gas purge system

Yes

N/A, there is no smoke/gas purge system.

The deflagration vents and/or exhaust outlets

Yes

N/A, there is no deflagration

venting/explosion prevention system.

updated March 2024 (Apply/Pay)

This study material is provided for free to the public. Page 14

On this _________ day of __________________________, in the year __________, I have hereunto

affixed my signature and I affirm that all statements made on this application are true under the

penalties of perjury. I understand that:

• any intentional falsification of this letter can be grounds for the denial, non-renewal, suspension

or revocation of the Certificate of Fitness as applies to the applicant;

• all statements made in connection with the application are subject to investigation and

verification;

• the FDNY representative may ask the B-28/W-28 Certificate of Fitness holder without prior

notice to demonstrate the required knowledge listed in this verification letter to verify his/her

proficiency in supervising the energy storage system upon inspection.

____________________________________________ ____________________

Printed Name of owner, manufacturer or installer Job Title

____________________

Signature of owner, manufacture or

installer

(Sign only before a Notary)

___________________

Signature of Notary

NOTARY PUBLIC: [Notary Seal]

My commission expires: ___/___/____

updated March 2024 (Apply/Pay)

This study material is provided for free to the public. Page 15

B-28/W-28 Sample Recommendation Letter

COMPANY NAME

BUSINESS ADDRESS

Fire Department Date: ____________

Bureau of Fire Prevention

9 Metro Tech Center

Brooklyn, NY 11201-3857

Dear Sir/Madam:

I am pleased to recommend ______________________________ (Name of Applicant) to apply for the:

B-28 Certificate of Fitness to supervise the stationary energy storage system (ESS) located at:

_____________________________________________________________________________

W-28 Certificate of Fitness to supervise the mobile energy storage system (approved locations are

listed in the Energy Storage System Training Verification Letter)

He/she has _____________ (Years/Months) of relevant experience and has obtained all required training

regarding the energy storage system mentioned in the Training Verification Letter from the qualified personnel. I

confirm that this candidate has been trained and is capable in supervising the energy storage system and providing

required information to the first responders during a fire or non-fire emergency incident. This candidate is of good

character and is physically able to perform the functions required by this Certificate of Fitness.

I affirm that the candidate has also been trained and is knowledgeable about the

the operational purpose of this system and the area(s) served by this system

and the locations of

the Fire Department Connection N/A; the manual pull stations N/A

the hydrants N/A; the standpipe systems N/A

This energy storage system (ESS) is an indoor system. N/A

I affirm that the candidate has also been trained and is knowledgeable about the

the location(s) and types of the portable fire extinguishers (the candidate knows whether or not the

portable fire extinguishers can be used on the energy storage system)

Building Information Card (BIC) N/A

Fire and Emergency Preparedness Plans N/A

On this _________ day of ___________________, in the year __________, I have hereunto affixed my signature

and I affirm that all statements made on this form are true under the penalties of perjury. I understand that

• all statements made in connection with the application are subject to investigation and verification

• any intentional falsification of this letter can be grounds for the denial, non-renewal, suspension or

revocation of the B-28/W-28 Certificate of Fitness as applies to the candidate

• FDNY representative may question the B-28/W-28 Certificate of Fitness holder as to the required building

or site information listed above to verify their knowledge during inspection.

________________________ _________________________ _________________________

(Printed name of Employer) (Employer’s title) (Signature of Employer)

NOTE: The recommendation letter should be on employer’s letterhead. If not on employer’s letterhead, signature must be notarized.

updated March 2024 (Apply/Pay)

This study material is provided for free to the public. Page 16

STUDY MATERIAL AND TEST DESCRIPTION

About the Study Material

This material will help you prepare for the examination for the Certificate of Fitness for Supervision of

Stationary Energy Storage System. The exam covers this entire booklet, but not the appendix. It will not

be provided to you during the test. It is critical that you read and understand this booklet to help

increase your chance of passing this exam. The reference material will be provided to you during

exam. The study material does not contain all of the information you need to know to supervise the

energy storage system (ESS). It is your responsibility to become familiar with all applicable rules and

regulations of the City of New York, even if they are not covered in this study material. In order to

properly prepare for this exam, you need to be familiar with the 2022 New York City Fire Code sections

FC608, FC901.6, and FC907, Fire Department Rules 3RCNY 608-01 and 3RCNY 907-01, and NFPA

855 (2022 Ed.).

About the Test

The B-28/W-28 exam will consist of 75 multiple choice questions, administered on a “touch screen”

computer monitor. It is a time-limited test. Only one answer is correct for each question. If you DO NOT

answer a question or mark more than one alternative, your answer will be scored as incorrect. A score

of 70% correct is required on the examination in order to secure a Certificate of Fitness. Read each

question carefully before marking your answer. There is no penalty for guessing.

Sample Questions

The following questions represent the “format” of the exam questions,

not the content of the real exam.

1. Which of the following are allowed to be used/displayed while taking a Certificate of Fitness

examination at 9 Metro Tech Center?

I. cellular phone

II. Study material booklet

III. Reference material provided by the FDNY

IV. Mp3 player

A. III only

B. I, II, and III

C. II and IV

D. I only

Only reference material provided by the FDNY is allowed to be used during Certificate of Fitness

examinations. Therefore, the correct answer would be A. You would touch “A” on the computer

terminal screen.

updated March 2024 (Apply/Pay)

This study material is provided for free to the public. Page 17

2. If you do not know the answer to a question while taking an examination, whom should you

ask for help?

A. the person next to you

B. the firefighters

C. the examiner in the testing room

D. you should not ask about test questions since FDNY staff cannot assist applicants

You should not ask about examination questions or answers since FDNY staff cannot assist applicants

with their tests. Therefore, the correct answer would be D. You would touch "D" on the computer

terminal screen.

3. If the screen on your computer terminal freezes during your examination, whom should you

ask for help?

A. the person next to you

B. the firefighters

C. the examiner in the testing room

D. the computer help desk

If you have a computer related question, you should ask the examiner in the testing room. Therefore,

the correct answer would be C. You would touch C. You would touch "C" on the computer terminal

screen.

updated March 2024 (Apply/Pay)

This study material is provided for free to the public. Page 18

INTRODUCTION

This study material will help you prepare for the written examination for the B-28/W-28 Certificate of

Fitness (COF) for Supervision of Energy Storage Systems (ESS).

B-28/W-28 Certificate of Fitness holders should be aware that they may be required to demonstrate

their knowledge and proficiency in their duties related to their Certificate at the time of original and

renewal applications, and at any time Fire Department representatives are conducting an inspection of

a premises. The Fire Department (FDNY) can deny, not renew, suspend or revoke a Certificate of

Fitness for misconduct, which would include the failure of the Certificate of Fitness holder to properly

fulfill their duty for any reason.

The Certificate of Fitness holder must keep the Certificate of Fitness readily available for inspection by

any representative of the Fire Department and at all times while operating or supervising an energy

storage system (ESS) facility for which the Certificate of Fitness is required.

In addition to any other penalties provided by law, misconduct on the part of an applicant or holder of

a Certificate of Fitness shall be grounds for denial, non-renewal, suspension or revocation of a

certificate, and denial of an application for a certificate or the opportunity to take a certificate

examination. Such misconduct includes, but is not limited to:

• The failure of Certificate of Fitness holders to properly fulfill their duties

o i.e. COF holders will be held accountable when they fail to report a spill, fire, excessive

smoking/vaporizing or smoldering, or any other hazardous condition, and they may

have their Certificate of Fitness revoked for such failure.

• Any false and fraudulent conduct in connection with an application for a certificate or the

duties of a certificate holder, including:

o False or fraudulent statements or submissions

o Unauthorized changes or use of a Certificate of Fitness or possession of a fraudulent

Certificate of Fitness

o Cheating on Certificate of Fitness examination

o Impersonating another person or allowing oneself to be impersonated

• The failure of Certificate of Fitness holders to promptly notify the Fire Department of any

change in the applicant’s or Certificate of Fitness holder’s residence address, or work location

• Any other conduct that decreases the integrity or reliability of an applicant or Certificate of

Fitness holder

• Compromising the integrity or confidentiality of a Fire Department examination

updated March 2024 (Apply/Pay)

This study material is provided for free to the public. Page 19

PURPOSE OF FIRE CODE Section 608

The Fire Code Section 608 govern all energy storage systems, including emergency power, standby

power, uninterruptible power and mobile systems.

PURPOSE OF RULE 3 RCNY 608-01

The rule 3 RCNY 608-01 was adopted to establish standards, requirements and procedures for the

design, installation, operation, inspection, maintenance, and decommissioning of outdoor/rooftop

stationary storage energy storage systems and mobile energy storage systems. All outdoor/rooftop

stationary energy storage systems or mobile energy storage systems shall additionally comply with this

Rule requirements.

PURPOSE OF THE STUDY MATERIAL

The study material includes information taken from the 2022 NYC Fire Code, NYC Fire Department

Rules, and various NFPA standards.

Unless otherwise specified, all requirements apply to the outdoor stationary energy storage

system should also apply to the rooftop stationary energy storage system or mobile energy

storage system.

This study material covers:

(1) Indoor/outdoor/rooftop stationary storage systems that use various types of new energy storage

technologies, including lithium-ion, flow, lead acid, nickel-cadmium and nickel metal hydride

batteries.

(2) All energy storage uses, including stationary energy storage systems installed on a mobile trailer

(or other form of mobile installation).

This study material does NOT cover:

Outdoor stationary energy storage systems with an aggregate rated energy capacity of not more than

250 kWh that are a component of individual electric motor vehicle (EV) charging stations and used for

the purpose of EV charging.

updated March 2024 (Apply/Pay)

This study material is provided for free to the public. Page 20

DEFINITIONS

Abnormal Conditions. When one or more parameters that govern the operation of a system are

outside their control limits.

Alarm Signal. A signal indicating an emergency requiring immediate action, such as a signal

indicative of fire.

Ampere-Hour (Ah). Ah is an abbreviation for ampere-hour, or amp-hour. This describes the charge

capacity of a battery, or how much current can be delivered at a constant rate as the battery is depleted

over the course of one hour.

Approved. Acceptable to the Fire Commissioner. In reference to construction documents, the

determination by the Fire Department after full examination that submitted construction documents

comply with NYC Fire Code and other applicable laws and rules. In reference to materials, the

determination by the commissioner that material is acceptable for its intended use.

Authority Having Jurisdiction (AHJ). An organization, office, or individual responsible for

enforcing the requirements of a code or standard, or for approving equipment, materials, an

installation, or a procedure.

Automatic. As applied to fire protection devices, any device, equipment or system that initiates system

function as a result of a predetermined temperature rise, rate of temperature rise, or combustion

products, without the necessity for human intervention.

Battery Module. A module consists of number of cells generally connected in either series or parallel.

Battery String. A battery string or bank comprises a number of cells/batteries connected in. series to

produce a battery or battery string with the required usable voltage/potential e.g. 6V, 12V, 24V, 48V,

110V. Ah.

ESMS (Energy Storage Management System). A system that monitors, controls, and optimizes

performance of an individual or multiple battery modules in an energy storage system and has the

ability to control the disconnection of the module(s) from the system in the event of abnormal

conditions. This system can be completely independent of the Energy Storage Management System.

Battery Rack. A device used to vertically store battery modules.

Cell. A single connection between the plates and electrolyte which produces a specific voltage (i.e. one

AA battery has one cell). In battery systems there are multiple cells in order to provide enough voltage

and energy for the entire load.

Central Station. A facility that receives alarm signals from a protected premises and re-transmits or

otherwise reports such alarm signals to the Fire Department.

Certificate of Approval. A written statement issued by the FDNY commissioner, certifying that an

article, device or equipment, or type, class or kind thereof, has been examined, tested and approved for

a specific purpose or use in conformity with the requirements of the construction codes, the Fire Code

or the Fire Department Rules.

updated March 2024 (Apply/Pay)

This study material is provided for free to the public. Page 21

Commissioning of the System. A systematic process that provides documented confirmation that the

stationary energy storage system and all associated fire protection systems function according to the

intended design criteria set forth in the project documents and satisfy the operator and/or owner’s

operational needs, including compliance with applicable laws, regulations, codes, and standards. This

process should also include verification that the energy storage system has been installed and activated

in accordance with manufacturer’s specifications.

Converters. Convert the voltage of an electric device, usually alternating current (AC) to direct

current (DC).

Decommissioning of the System. A process that verifies and documents that the energy storage

system has been completely and safely removed from service and the hazardous components properly

disposed of in accordance with minimum code requirements, applicable regulations and

manufacturer’s instructions. Decommissioning can be Emergency Decommissioning; required when

the ESS suffers a thermal runaway or other failure or Planned Decommissioning; which occurs at the

expected termination of the ESS when it reaches the end of its useful life.

Dedicated Use Building. A building housing a stationary energy storage system that 44 allows human

entry (walk-in) but is not designed or used for human occupancy.

Deflagration. Propagation of a rapid combustion zone creating over-pressure at a velocity that is less

than the speed of sound in the unreacted medium, which may be caused by a thermal runaway

condition. (NFPA 68-2018: Standard on explosion Protection by Deflagration Venting.)

Disconnect Switch. The purpose of this switch is to electrically isolate the ESS from the utility grid

and provide a physical break in the electrical circuit. (See e-stop).

Direct Current. As opposed to alternating current or AC which is commonly found in homes and

business batteries produce direct current or DC. Note: Non-contact voltage testers will NOT detect

direct current. These devices were designed to detect alternating current as the devices can see the

alternating wave form of AC.

E-Stop. An emergency device used to stop an energy storage system from charging. Note: It will NOT

deplete the energy already stored within the batteries associated with the system. (See disconnect

switch).

Energy Storage Systems (ESS), Stationary.

A rechargeable system for the storage of electrochemical energy, designed as a stationary installation

(including mobile systems) and consisting of one or more interconnected storage batteries, capacitors,

inverters and other electrical equipment. A stationary energy storage system is typically used to

provide electrical power and includes associated fire protection, explosion mitigation, ventilation

and/or exhaust systems. Stationary energy storage systems include the following types of systems:

• Indoor System. A stationary energy storage system installed inside a building.

• Mobile System. A stationary energy storage system mounted on a trailer or otherwise installed

for mobile use.

updated March 2024 (Apply/Pay)

This study material is provided for free to the public. Page 22

• Outdoor System. A stationary energy storage system installed outdoors, including mobile

systems and systems installed on a rooftop.

One or more devices, assembled together, capable of storing energy in order to supply electrical energy

at a future time to the local power loads, to the utility grid, or for grid support.

Fire Alarm Control Panel. FACP is a system component that monitors inputs and control outputs

through various circuits. The primary purpose of the fire alarm control panel is to process signals

received from initiating devices and to activate appropriate signals and outputs.

Fire Alarm Box, Manual. A manually operated device used to initiate an alarm signal.

Fire Alarm Signal. A signal initiated by a fire alarm-initiating device such as a manual fire alarm box,

automatic fire detector, water-flow switch, or other device whose activation is indicative of the

presence of a fire or fire signature.

Fire Alarm System. Any system, including any interconnected fire alarm sub-system, of components

and circuits arranged to monitor and annunciate the status of fire alarm or supervisory signal-initiating

devices.

Fire Apparatus Access Road. A road that serves to provide access for fire apparatus from a public

street to the frontage space of one or more buildings not directly fronting on a public street. A fire

apparatus access road includes any road that serves such purpose whether denominated as a driveway,

parking lot lane, private road or private street.

Fire Department Connections (FDC). A connection, normally on the exterior of the building,

through which the Fire Department can pump supplemental water into the sprinkler system, standpipe,

or other system furnishing water for fire extinguishment to supplement existing water supplies

(formerly known as a Siamese connection).

Fire Detector, Automatic. A device designed to detect the presence of a fire signature and to initiate

action.

Fire Extinguishing System. An approved system of devices and equipment which detects a fire and

discharges an approved fire extinguishing agent onto or in the area of a fire. Such term includes

automatic systems and, where such systems are authorized by this code or the Building Code,

manually activated systems.

Fire Protection System. Approved devices, equipment and systems or combinations of systems used

to detect a fire, activate an alarm, extinguish or control a fire, control or manage smoke and products of

a fire or any combination thereof, including fire extinguishing systems, fire alarm systems, sprinkler

systems and standpipe systems.

Gas Detection System. A system or portion of a combination system that utilizes one or more

stationary sensors to detect the presence of a specified gas at a specified concentration and initiate one

or more responses required by this code, such as notifying a responsible person, activating an alarm

signal, or activating or deactivating equipment. A self-contained gas detection and alarm device is not

classified as a gas detection system.

updated March 2024 (Apply/Pay)

This study material is provided for free to the public. Page 23

Initiating Device. A system component that originates transmission of a change-of-state condition,

such as in a smoke detector, manual fire alarm box, or supervisory switch.

Inverters. Convert direct current (DC) to alternating current (AC).

Immediately. Without any delay, but up to a maximum of 15 minutes.

Kilowatt-Hour (kWh). A measurement of electrical energy. KWh is an abbreviation for kilowatt hour.

If energy is transmitted or used at a constant rate (power) over a period of time, the total energy in

kilowatt hours is equal to the power in kilowatts multiplied by the time in hours. The kilowatt hour is

commonly used as a billing unit for energy delivered to consumers by electric utilities.

Listed. A material, device, equipment or system included on a list published by a nationally

recognized testing laboratory or other approved organization performing product evaluations that

maintains periodic inspection of production of such listed material, device, equipment or system, and

whose listing indicates compliance with nationally recognized standards and designates suitable usage.

Megawatt Hours (MWh). A measurement of electrical energy.

Out-of-Service System. A fire protection system that is not fully functional; or whose operation is

impaired or is otherwise not in good working order.

One-Way Emergency Communications System. One-way emergency communications systems are

intended to broadcast information, in an emergency, to people in one or more specified indoor or

outdoor areas. It is intended that emergency messages be conveyed either by audible, visible, or textual

means, or by any combination thereof.

Pre-Signal System. A fire alarm system having a feature that allows initial fire alarm signals to sound

in a constantly attended central location and for which a human action is subsequently required to

achieve a general alarm, or a feature that allows the control equipment to delay the general alarm by

more than one minute (but not more than 3 minutes) after the start of the alarm processing.

Recommissioning of an Existing System. A process that verifies and documents that a repaired or

reconditioned energy storage system functions in accordance with its initial commissioning and

according to minimum code requirements, listing requirements and manufacturer’s published

instructions.

Residential Group R Occupancies.

Group R-1 occupancies containing sleeping units where the occupants are primarily transient in

nature, including:

Boarding houses (transient) with more than 10 occupants

Congregate living facilities (transient) with more than 10 occupants

Hotels/Motels (transient)

Group R-2 occupancies containing sleeping units or more than two dwelling units where the

occupants are primarily permanent in nature, including:

Apartment houses

updated March 2024 (Apply/Pay)

This study material is provided for free to the public. Page 24

Congregate living facilities (non-transient) with more than 16 occupants, including boarding

houses (non-transient), convents, dormitories, fraternities and sororities, monasteries

Hotels/Motels (non-transient)

Vacation timeshare properties

Group R-3 occupancies where the occupants are primarily permanent in nature and not classified as

R-1, R-2, R-4 or I, including:

Buildings that do not contain more than two dwelling units

Care facilities that provide accommodations for five or fewer persons receiving care

Congregate living facilities (non-transient) with 16 or fewer occupants, including boarding

houses (non-transient), convents, dormitories, fraternities and sororities, monasteries.

Lodging houses (transient) with 5 or fewer guest rooms and 10 or fewer occupants

Safety Data Sheet (SDS). A document prepared in accordance with the regulations of the United

States Department of Labor, as set forth in 29 CFR Part 1910.1200 or a federally approved state

OSHA plan which sets forth information concerning a hazardous material. An SDS is a standardized

document that contains important occupational safety and health hazard data for workers and

emergency first responders.

Smoke Detector. A listed device that senses visible or invisible particles of combustion.

Standpipe System. Piping installed in a building or structure that serves to transfer water from a

water supply to hose connections at one or more locations in a building or structure for fire-fighting

purposes.

Storage Battery. An electrochemical device, equipment or system designed to store and generate

electrical energy.

Storage Battery Types

Flow battery. A storage battery that stores and generates an electrical current by ion exchange

through a membrane separating liquid electrolytes.

Lead acid battery. A storage battery that is comprised of lead electrodes immersed in sulfuric

acid electrolyte, including vented (flooded) or valve regulated lead acid (VRLA) batteries.

Valve-regulated lead-acid (VRLA) battery. A lead-acid battery consisting of sealed cells

furnished with a valve that opens to vent the battery whenever the internal pressure of the

battery exceeds the ambient pressure by a set amount. In VRLA batteries, the liquid

electrolyte in the cells is immobilized in an absorptive glass mat (AGM cells or batteries) or

by the addition of a gelling agent (gel cells or gelled batteries).

Vented (flooded) lead-acid battery. A lead-acid battery consisting of cells that have

electrodes immersed in liquid electrolyte. Flooded lead-acid batteries have a provision for the

user to add water to the cell and are equipped with a flame-arresting vent that permits the

escape of hydrogen and oxygen gas from the cell in a diffused manner such that a spark, or

updated March 2024 (Apply/Pay)

This study material is provided for free to the public. Page 25

other ignition source, outside the cell will not ignite the gases inside the cell.

Lithium-ion (Li-ion) battery. A storage battery in which an electrical current is generated by

lithium ions embedded in a carbon graphite or nickel metal-oxide substrate placed in a high-

viscosity carbonate mixture or gelled polymer electrolyte.

Lithium Metal Polymer Battery. A storage battery in which an electrical current is generated by

the interaction between lithiated positive active material electrically separated from metallic

lithium or lithiated negative active material, and nonaqueous liquid or polymerized electrolytes.

Nickel Cadmium (Ni-Cd) Battery. An alkaline storage battery in which the positive active

material is nickel oxide, the negative active material contains cadmium, and the electrolyte is

potassium hydroxide.

Nickel Metal Hydride (NiMH) Battery. An alkaline storage battery in which the positive active

material is nickel oxide, the negative active material is a hydrogen- absorbing alloy, and the

electrolyte is potassium hydroxide.

Nonrecombinant Battery. A storage battery in which, under conditions of normal use, 26

hydrogen and oxygen gases created by electrolysis are vented into the air outside of the battery.

Recombinant Battery. A storage battery in which, under conditions of normal use, hydrogen 29

and oxygen gases created by electrolysis are converted into water inside the battery instead of 30

venting into the air outside of the battery.

Stationary storage battery. A storage battery designed for use in a stationary installation, in

which electrochemical cells are interconnected to supply a nominal voltage of direct current power.

The nominal voltage rating of a stationary storage battery is a function of the number of cells

connected in a series, and the discharge capacity is a function of the size of the cells. Stationary

storage batteries are characterized by their ability to be restored to a fully charged condition by

reversing the flow of the electric current after discharge.

Storage Battery Unit. A storage battery system in the configuration in which it was tested and listed

to Underwriters Laboratories Standard 9540 (UL Standard 9540), including any cabinet or other

enclosure.

Shall. Indicates a mandatory requirement.

Should. Indicates a recommendation or that which is advised but not required.

Supervisory Signal. A signal indicating the need for action in connection with the supervision of

guard tours, fire extinguishing systems or equipment, fire alarm systems or the maintenance features of

related systems.

Thermal Imaging Camera. (TIC) is a thermographic camera that converts infrared light emitted from

surfaces to visible light, displayed by the camera’s viewing screen. Such cameras allow firefighters to

see areas of heat or thermal energy through smoke, darkness, or heat-permeable barriers. Thermal

imagers also enable the inspection of equipment for abnormal operation (e.g., loose connections,

overloaded components, loss of coolant, moisture intrusion, etc.)

Thermal runway. The condition when an electrochemical battery cell increases its temperature

updated March 2024 (Apply/Pay)

This study material is provided for free to the public. Page 26

through self-heating in an uncontrollable fashion. The thermal runaway progresses when the cells

generation of heat is at a higher rate than the heat it can dissipate. Thermal runaway may lead to off-

gassing, fire and deflagration.

Trouble Signal. A signal initiated by the fire alarm system or device indicative of a fault in a

monitored circuit or component.

Two-Way Emergency Communications System. Two-way emergency communications systems are

divided into two categories, those systems that are anticipated to be used by building occupants and

those systems that are to be used by fire fighters, police, and other emergency services personnel.

Two-way emergency communications systems are used to both exchange information and to

communicate information such as, but not limited to, instructions, acknowledgement of receipt of

messages, condition of local environment, and condition of persons, and to give assurance that help is

on the way.

Unnecessary Alarm. An alarm signal transmitted by a fire alarm system which functioned as

designed, but for which a Fire Department response proved unnecessary. An example of an

unnecessary alarm is an alarm triggered by smoke from a lit cigarette in a non-smoking area, when the

presence of such smoke does not implicate fire safety concerns.

Unwarranted Alarm. An alarm signal transmitted by a fire alarm system which failed to function as

designed because of improper installation, improper maintenance, malfunction, or other factor.

Examples of unwarranted alarms are alarms resulting from improper smoke detector placement,

improper detector setting for installed location, lack of system maintenance, and control panel

malfunction.

updated March 2024 (Apply/Pay)

This study material is provided for free to the public. Page 27

CHAPTER 1. CASE STUDIES

The case studies mentioned below are for illustrative purposes to address some issues that may

be involved in energy storage system accidents. The case studies do not necessarily reflect the

overall incidents.

Sodium-Sulfur Battery Fire (Japan, 2011)

A 2 MW (i.e. 2000 KW) NAS (sodium-sulfur) energy storage system caught fire at the Mitsubishi

Materials Corporation plant in Tsukuba, Japan. It took firefighters more than eight hours to control the

blaze, and more than 2 weeks to extinguish it.

One faulty cell leaked electrolyte, which created an electrical short path that subsequently destroyed

other cells and lead to further heating. Heating was sufficient to cause a release of molten material,

which developed into a spreading fire.

Lesson learned:

The manufacturer identified the need for rapid detection of abnormal conditions in the monitoring

systems and physical barriers within the product design that limit fire spread and heat transfer during

failure events (compartmentalization).

Lead Acid Battery Fire (Oahu, Hawaii, USA, 2012)

The 10 MWh (i.e. 10000 kWh) lead acid battery system was used to buffer electricity smoothing out

spikes and low spots in wind power production. The blaze sparked in a metal warehouse with 12,000

lead acid batteries mounted in racks towering more than 6 feet high. An alarm sensor showed a buildup

of heat, and video cameras recorded a fire starting in the battery banks. Capacitors in the power

electronics are reported to be associated with the failure.

updated March 2024 (Apply/Pay)

This study material is provided for free to the public. Page 28

The risks from scalding heat, poisonous fumes, a collapsing structure and the potential for battery

explosions kept firefighters outside the warehouse.

The on-site supervisors from the facility suggested the firefighters to wait the fire extinguish itself.

However, the stubborn blaze burned for more than 13 hours and continued to smolder after 36 hours.

The response team decided to use a defensive fire attack by focusing on keeping the blaze from

spreading to other buildings at the site.

The team used water to cool parts of the building but avoided using it to extinguish the fire out of

concerns for electric shock and risks of creating toxic chemical runoff. Instead, they waited for a

carbon dioxide extinguishing system to arrive on the scene, but that proved ineffective at quenching

the inferno.

Lesson learned:

There should be representative(s) who is/are knowledgeable to provide the information of the battery

system and suggest the effective extinguishing methods. So that the firefighters will not have to

extinguish a blaze without knowing what chemicals are in play, where the electrical shutoffs are or

what kind of fire retardant to use.

Developers and responders need to take proactive steps to ensure they know what they are dealing with

when an accident occurs.

Lithium-ion batteries fire (PORT ANGELES, WA, USA, 2013)

The 50kWh batteries system caught fire at The Landing mall, triggering an evacuation of between 50

and 100 people from the waterfront landmark and closures of surrounding streets and City Pier. The

batteries are part of a “green energy” system that stores excess power to the building during low power

usage, and feeds it back into the system during times of high usage. An electrical fault in the battery

system was thought to have caused the fire.

The fire was announced to be extinguished after 2.5 hours.

updated March 2024 (Apply/Pay)

This study material is provided for free to the public. Page 29

After the incident, the system was isolated from rest of The Landing mall. However, few days later, the

batteries caught fire again. The Fire Department found a single battery that had survived the first fire

holding enough to ignite and melt plastic around it.

Lesson learned:

The post-fire battery may re-ignite. The isolation and monitoring of the damaged battery system is

critical. There should be at least one watchperson to supervise the site 24/7. If the watchperson

becomes aware of a fire or other emergency at the site, he could immediately call 911 and report the

emergency. This watchperson should also ensure all entries and exits on the ground level to the site are

properly secured. It can reduce the chance of entry by unauthorized persons.

Lithium-ion batteries fire (Franklin, WI, USA, 2016)

The fire began in a utility-scale energy storage system that was still under construction. These batteries

were not being charged or discharged and were not connected to a power source or load. The fire

started in one of that battery manufacturer’s DC power and control compartments of a battery rack

within the energy storage system, and once the fire was started in the battery rack DC Power and

control compartment it spread to the adjacent batteries.

The fire departments found that the fire was still contained to the single container, but the batteries

were indeed releasing their stored energy, which resulted in a lot of smoke and a lot of heat. The reality

is that lithium-ion batteries are very energy dense, and once they start releasing their energy, the

priority is controlling the pace at which they release that energy. After reading the SDS, the first step

the fire department took was to use foam as a precautionary measure. Once the foam was applied, the

local fire departments used 500 gallons per minute of water to cool the batteries. Water was

appropriately used on these lithium-ion batteries, as listed on the SDS. The water didn’t put out the

fire, but it did control the spread of heat from the fire.

After few hours, there was no fuel remaining and the fire extinguished.

Lesson learned:

The facility staff is on-site to provide advice to the first responders. Water is considered the best

possible extinguishment for lithium ion battery fires to keep the batteries cool in order to keep the fire

localized to the container.

updated March 2024 (Apply/Pay)

This study material is provided for free to the public. Page 30

Compartmentalization (limiting the amount of material in a space and providing physical barriers

between equipment areas) was critical in limiting the extent of the fire spread. Safety data sheets do not

contain sufficient information for emergency response to battery system fires. Manufacturers,

installers, and fire protection professionals must provide fire mitigation strategies (e.g., containment

and suppression) and collaborate with the fire department to develop a thorough emergency response

plan.

Lithium Ion Battery Fire (Belgium, 2017)

The fire occurred during the commissioning phase at the battery container at the utility company’s test

site. The 6MW project was the first time an ESS was to be used for grid Frequency Containment

Reserve services in Belgium.

The firefighters arrived rapidly at the site and took several hours for firefighters to control the fire. The

fire did not extend to the other containers or other parts of the site. The firefighters have continued to

water the containers in order to cool them down.

Lesson learned:

Compartmentalization is critical. Water is considered the best possible extinguishment for lithium ion

battery fires to keep the batteries cool.

Twenty-three Fires at different Lithium-ion stationary storage battery systems (South Korea,

2017-2018)

updated March 2024 (Apply/Pay)

This study material is provided for free to the public. Page 31

Twenty-three energy storage system fires that have occurred in South Korea since August of 2017. The

lithium-ion battery fires resulted in system losses valued at over $32M USD. In January, the

government requested to stop operation of existing systems, which resulted the shutdown of 522 ESS

units – approximately 35% of the budding market.

Lesson learned:

The government formed an investigation committee of academics, research institutions, laboratories

and ESS industry experts to investigate the causes of the fires. Their report was released in 2019 and

included four causes for the fires:

1. Insufficient battery protection systems against electric shock.

Systems were not able to properly protect against electrical hazards due to ground faults or short

circuits.

2. Inadequate management of operating environment.

Of the 23 fire incidents that occurred, 18 were installed in the mountains or coastal areas. It was

concluded that these environments resulted in harsh conditions including large temperature swings,

high humidity and elevated levels of dust and particulates which ultimately led to failure modes

resulting in fires.

3. Faulty Installations.

It was determined that human error during installations can also lead to system faults resulting in ESS

fires. There are some cases include faulty wiring or mechanical damage to the batteries during

installation were cited.

4. ESS System Integration.

The integrated protection and management systems were found to be insufficient with the ESS. It was

confirmed by the committee that gaps in the integration of the energy storage management system

(ESMS), energy management system (EMS), and power management system (PMS) can result in

conditions that lead to fire.