Tangless

®

AND Tanged

INSERTS & TOOLS

The single best source for helical coil inserts, tools and thread repair kits in the industry.

BS EN ISO 9001: 2000, Amended May 2003.

Certificate No. FM 20982

All dimensions expressed in inches unless

otherwise specified. Specifications subject to

change without notice.

KATO

®

Tangless

®

and Tanged CoilThread

®

Inserts and Tools are covered by existing

U.S. and foreign patents.

Tangless

®

, KATO

®

, CoilThread

®

, and

CoiLock

®

are all Registered Trademarks of

Kato Fastening Systems, Inc., and the

Advanex Group.

KATO

®

Fastening Systems Mission Statement:

"We F.A.S.T.E.N."

• FUTURE: At KFS our goal is to assure that our products stay a step ahead of the

fastener needs of the future. "We think tomorrow… today!"

• ADVANCED

:

Our manufacturing and quality systems are the most advanced in the

industry, and we have licensed this technology to our largest competitors!

• SERVICE: Satisfaction- Plus™ is your guarantee that if you are not satisfied with any

of our products, for any reason — simply return the unused parts for replacement, or

a full refund. No other insert manufacturer can make that promise!

• TECHNOLOGY: Our technology is recognized as being the best in the industry. Using

our network of global resources, we developed the innovative line of Tangless®

Inserts & Tools!

• EXCELLENCE: Our goal is for the KFS name to be synonymous with an unsur-

passed level of excellence and distinction in the industry.

• NEXT: Complacency is not in our vocabulary. We are constantly working on the

next generation of fasteners and tools.

Copyright KFS 2003 15M

ISO Certification

1

Tangless or Tanged...it’s your choice. Your best

source for both is CoilThread

®

from KATO

®

!

Tangless Inserts:

FOD-Free Design: No tangs to break off, retrieve...or lose.

Approved for use on military programs by NASM8846 and NAS1130.

Cost Reduction: Significantly decreased installation and inspection time.

Bi-directional design eliminates insert orientation requirement.

Quick, non-destructive removal prevents damage to castings.

Tangless Inserts meet the requirements of NAS1130 and NASM8846, and were added to NASM8846, the

procurement standard for helical coil inserts to give you the option to use the Tangless design on military

programs. Paragraph 6.3.1 of NASM8846 states “The decision to select tanged inserts or tangless

inserts shall be made by the design activity.”

Tangless Inserts are designed to replace tanged helical coil inserts as specified

in NASM122076 and NASM124651 series (standard thread) and NASM21209

(locking thread); they install in standard STI tapped holes per NASM33537.

Installed inserts provide a finished thread meeting the requirements

of FED-STD-H28/2 and accept standard bolts or screws (MIL-S-7742)

or UNJ (MIL-S-8879).

Tanged Inserts:

Lower pricing than competitive inserts.

Complete range of locking and free-running sizes, bulk or strip-feed, including metric.

Full line of taps, gages, hand tools, air tools, and electric tools

available...interchangeable with and will install all major brands

of inserts.

Meet or exceed all applicable military, aerospace, and

commercial standards. Full traceability.

Design and Application Assistance: over 25 years of

manufacturing and engineering experience.

®

2

In either their tanged or Tangless configurations,

CoilThread Inserts are economical, helically-coiled fasten-

ing devices that provide permanent, wear-resistant screw

threads that exceed the strength of most parent materials.

They protect tapped threads against failures due to strip-

ping, seizing, corrosion and wear. They save time and

money because of their low initial cost and permit flexibili-

ty of installation when using Kato tools detailed in the tool-

ing section of the catalog.

CoilThread Inserts are made of cold-rolled Type 304 stain-

less steel wire (AS7245), work-hardened to a tensile

strength above 200,000 psi and a hardness of Rc43-50.

The finished surface (8-16 microinches) is exceedingly

smooth, virtually eliminating friction-induced thread ero-

sion.

When assembled in STI tapped holes, CoilThread Inserts

form Unified Coarse or Unified Fine threads that conform to

National Bureau of Standards Handbook H-28, Screw-

Thread Standards for Federal Services, Classes 2B and 3B.

Assembled CoilThread Inserts will also accommodate UNJ,

MIL-S-8879, male threaded fasteners.

Contents Pages

Tanged and Tangless

®

CoilThread

®

Helical Coil Inserts

–Inch and Metric Sizes

• Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

• Performance and Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

• Applicable Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

• Design Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

• Installation Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

• STI Taps and Gages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Tangless CoilThread Inserts and Tools

–Inch Sizes

• Insert Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

• Cross Reference Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

• Prewinder-Type Hand Inserting Tools . . . . . . . . . . . . . . . . . . . 22

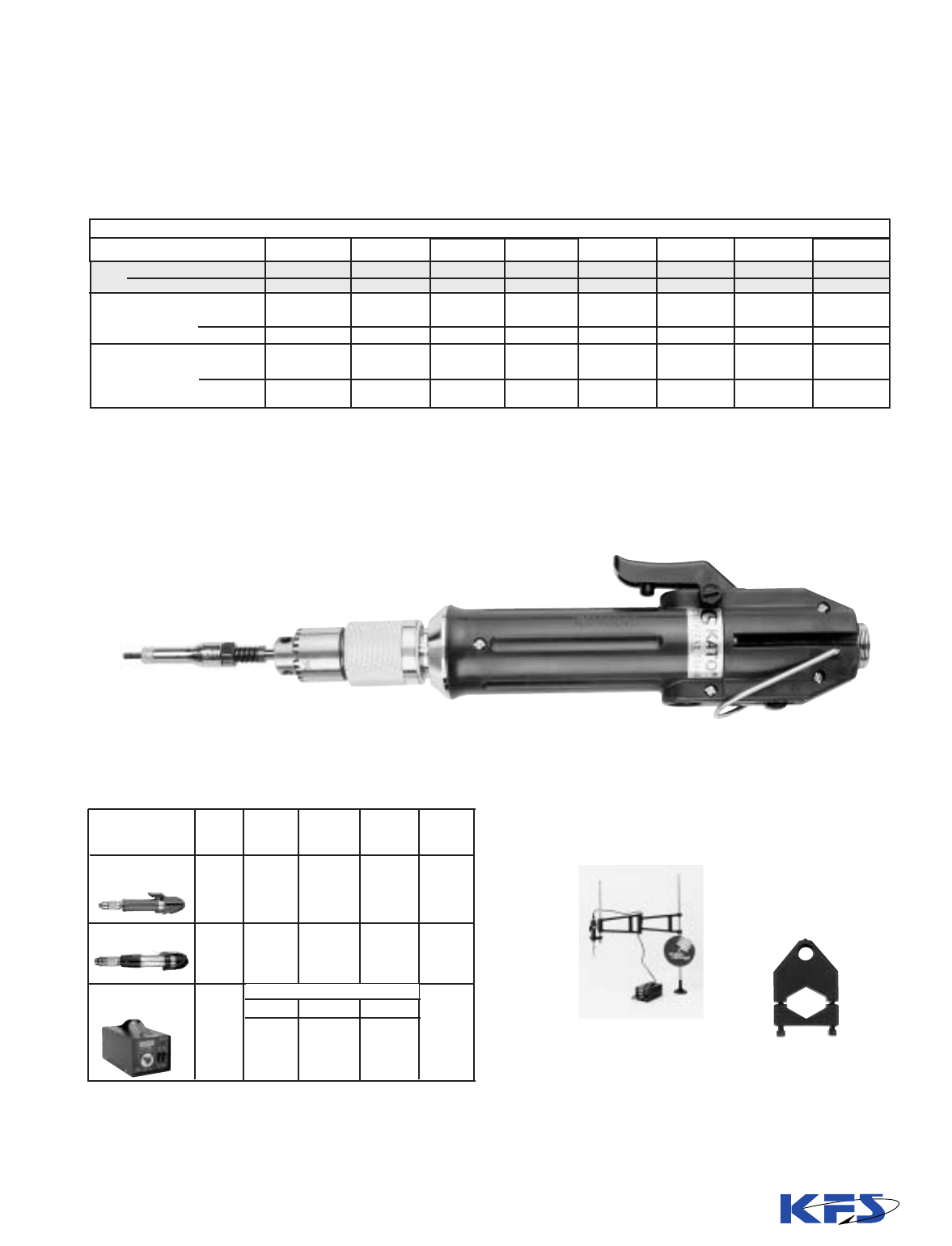

• Air Driven Inserting Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

• Keyless Chuck Electric Driver . . . . . . . . . . . . . . . . . . . . . . . . . 23

• Hex Shank Insertion Mandrels . . . . . . . . . . . . . . . . . . . . . . . . 24

• Mandrel-Type Inserting and Removal Tools. . . . . . . . . . . . . . . 24

Tangless CoilThread Inserts and Tools

–Metric sizes

• Insert Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

• Prewinder-Type Hand and Hex Shank Inserting Tools . . . . . . . 28

• Removal Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

• Air Driven Inserting Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Tanged CoilThread Inserts and Tools

–Inch Sizes

• Insert Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

• Cross Reference Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

• Hand Inserting Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

• Air Driven Inserting Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

• Electric Inserting Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

• Tang Break-Off & Extracting Tools . . . . . . . . . . . . . . . . . . . . . 42

Tanged CoilThread Inserts and Tools

–Metric sizes

• Insert Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

• Cross Reference Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

• Hand Inserting Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

• Air Driven Inserting Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

• Electric Inserting Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

• Tang Break-Off & Extracting Tools . . . . . . . . . . . . . . . . . . . . . 50

Kato-Kits

TM

- Thread Repair Kits

• Inch Size Kits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

• Metric Size Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

• Spark Plug & Pipe Thread Kits . . . . . . . . . . . . . . . . . . . . . . . . 53

HEXATORQ

TM

- Constant Torque Hinges. . . . . . . . 54

Tooling Guide - On Line. . . . . . . . . . . . . . . . . . . . . . . . . . 56

Technical Articles . . . . . . . . . . . . . . . . . . . . Inside back cover

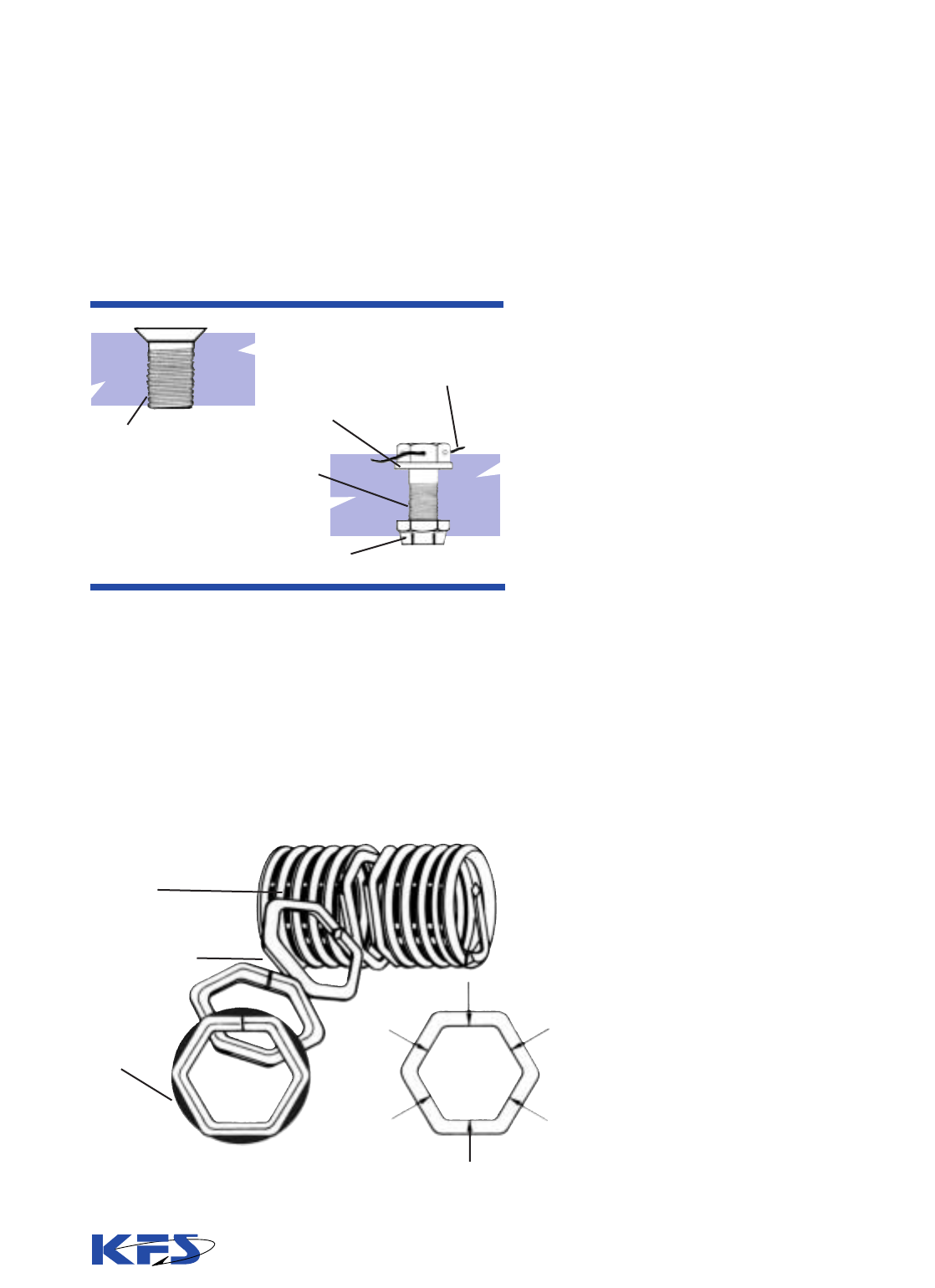

CoilThread Inserts

®

CoilThread Inserts are precision-formed continuous heli-

cal coils. With minimal wall thickness, they are the most

compact and lightweight inserts available.

Cross section view shows just how little extra hole diam-

eter is needed to provide the outstanding thread strength

that CoilThread inserts offer.

®

3

HIGH TENSION ANCHOR

The high tensile coils of a CoilThread Insert undergo a diam-

eter reduction during installation. The outward spring-like

force of the coils“locks” the insert into place.

Each coil can flex independently to contact the greatest

amount of parent material thread surface. Both static and

dynamic load bearing capabilities are improved.

PARENT

MATERIAL

Performance & Features

CoilThread inserts improve the reliability of fastening systems.

The resilient characteristics of each coil in the

CoilThread insert allows it to adjust independently to

secure the maximum surface contact with individual

threads in the parent material. As a result, loads are

distributed more evenly. Stress and fatigue concen-

trations are reduced to maximize thread strength and

increase the reliability and life of the fastening

system.

The stainless steel used resists corrosion under nor-

mal environmental conditions. Galvanic action with-

in the thread assembly is reduced, further adding to

the life of the fastening assembly. These inserts are

used with temperatures from –320° F. to +800° F.

TANG

Used to drive insert into

tapped hole. Can be left

attached or removed per

requirements of the

application.

PREFORMED NOTCH

Simplifies removal of tang

if required.

DIAMOND SHAPED

CROSS SECTION

Keeps insert weight to a

minimum and allows the

smallest possible hole

diameter.

HARD WEAR-RESISTANT THREADS

Work-hardened, stainless steel forms a smooth, hard surface

that reduces thread wear and resists corrosion. Result: A highly

reliable, long-life insert.

COILOCK THREAD

LOCKING ELEMENT

CoiLock Self-Locking

Inserts incorporate one

or more coils with

straight run segments

that apply pressure to

and lock the threads of

the male fastener.

Additional information on

these Self-Locking

Inserts can be found on

Pages 6 and 7.

CoilThread Inserts provide design and

manufacturing flexibility.

Design opportunities are provided by the structure of

these inserts. Because of the continuous helically-coiled

design, they need no thick wall structure to support the

internal and external threads: the diamond-shaped coil is

the thread!

The inserts can be installed in reduced-size bosses or

flanges and within constricted areas, thus saving space

and weight while providing high strength. A boss radius

equal to the nominal bolt diameter is usually sufficient.

KATO Tools provide a choice of installation methods best

suited to specific production techniques. Convenient

hand tools can be supplied for small runs, repairs and

prototyping: or high-speed electric or air-powered tools

may be selected for rapid, low-cost installation.

CoilThread Inserts are available in Bulk and on Strip Feed

Reels...providing flexibility for any production set-up.

INDEPENDENT THREAD COILS

4

Corrosion Protection:

Corrosion is the deterioration of a metal because of a reaction

with its environment. The products of corrosion vary widely

from the flaky red rust of iron to the relatively benign oxide over

aluminum. In general, corrosion should be avoided or mini-

mized where possible.

There are many types of corrosion, but a particular type called

galvanic corrosion is most important for inserts and fasteners.

Galvanic corrosion occurs when dissimilar metals are in con-

tact in the presence of an electrolytic solution. All metals exhib-

it different degrees of “activity” or “nobility” and can be

arranged in a galvanic series of increasing activity. Gold and

platinum are most noble while zinc and magnesium are most

active. The most common electrolytic solution encountered is

ordinary water. Seawater or salt spray is more damaging

because of high concentrations of dissolved salts.

The best way to preclude galvanic corrosion is to use similar

potential metals and eliminate the electrolyte conductor. The

active stainless steel CoilThread Inserts are not passivated. This

minimizes the possibility of galvanic corrosion occurring when

they are installed in aluminum or magnesium parent materials.

Some additional precautions for reducing galvanic corrosion

are:

1. Isolate the fasteners from the electrolyte. This can be done

through gasketing or sealing.

2. Specify cadmium plated inserts. The cadmium plate pro-

vides a sacrificial barrier against corrosion. In addition, the cad-

mium plate has lubricating properties that minimize galling

when stainless steel screws are used.

3. Apply corrosion inhibiting pastes or compounds to the

screw. These include zinc chromate primer (MIL-P-8585) and

strontium chromate primer (MIL-P-23377). Note: Pastes

applied to the CoilThread Insert can become trapped between

the wire and the hole and cause loss of proper tolerance. It is

therefore recommended to apply the paste only to the screw,

not the insert. If zinc chromate primer is applied to the tapped

hole it should be thinned and applied sparingly. The insert

should be installed while the primer is still wet.

4. Specify a dry film lubricant such as molybdenum disulphide

on the inserts. This provides a secondary barrier against cor-

rosion.

5. Where practical or where it will not interfere with the com-

pleted assembly, the external joint should be coated with a suit-

able paint.

Military, Aerospace &

Commercial Standards

Performance & Features, continued

CoilThread Tanged and Tangless

®

Inserts are precision-

engineered and have been put through rigorous torque,

tension and vibration tests as well as comprehensive

dimensional inspections and metallurgical analysis in

attaining their MIL-Spec qualifications.

CoilThread Inserts have been thoroughly tested by an

independent testing laboratory and are certified to con-

form to NASM8846. Copies of these reports are available

upon request.

In addition, CoilThread Inserts and Tools are in confor-

mance with the following military standards and other

specifications:

Unified Inserts

NASM122076 series* – Insert, Corrosion Resistant

Helical Coil Coarse Thread

NASM124651 series* – Insert, Corrosion Resistant

Helical Coil Fine Thread

MS21208 – Insert-Screw Thread Free Running

(Superceded by MS122076 and

MS124651 series)

NASM21209* – Insert-Screw Thread Screw-Locking

NASM33537 – Assembly and Dimensions,

Helical Coil Inserts

NASM8846* – Inserts, Screw thread, Helical Coil

A-A-59158 – Tools for Inserting and Extracting

Helical Coil Inserts

AS7245 – Insert, Screw Thread, Helical Coil,

Corrosion Resistant Steel

QQ-P-416 – Cadmium Plating (Type II)

- Optional coating

AS5272 – Dry Film Lubricant (Type I)

- Optional coating

NAS1130 – Tangless Inserts, Free-running &

Locking

ASME B18.29.1 – Helical Coil, Screw Thread Inserts -

Free-Running & Locking

Metric Inserts

MA3279 – Inserts, Metric, Free-Running,

Helical Coil, Uncoated

MA3280 – Inserts, Metric, Free-Running,

Helical Coil, Lubricated

MA3281 – Inserts, Metric, Free-Running, Helical

Coil, Cadmium Plated

MA3329 – Inserts, Metric, Locking,

Helical Coil, Uncoated

MA3330 – Inserts, Metric, Locking,

Helical Coil, Lubricated

MA3331 – Inserts, Metric, Locking, Helical Coil,

Cadmium Plated.

MA1565 – Procurement Standard, Metric

Helical Coil Inserts

MA1567 – Assembly Dimensions,

Metric Helical Coil Inserts

* Note: In 1998 and 1999, the Military Specifications (MS) of the same

number were superceded by the NASM specifications.

2 2-1/2 3 3 ———— —

1-1/2 1-1/2 2 2-1/2 2-1/2 3 3 — —

1 1-1/2 1-1/2 2 2 2 2-1/2 3 3

111-1/2 1-1/2 1-1/2 2 2 2-1/2 2-1/2

1111-1/2 1-1/2 1-1/2 2 2 2-1/2

1 11111-1/2 1-1/2 1-1/2 2

1 1111111-1/2 1-1/2

Selection of Correct Insert Length

CoilThread Inserts are available in nominal thread sizes

from UNC #2 through 1-1/2,” and from UNF #3 through

1-1/2.” Metric sizes include M2.2 through M12. Five

insert lengths are available for each thread size.

It is important to select the correct insert length in order

to balance the bolt tensile strength against the shear

strength of the parent material.

These five insert lengths (recommended thread engage-

ment of the CoilThread Insert), 1, 1-1/2, 2, 2-1/2 and 3

are shown in the shaded area of the table below. These

are calculated numbers since the inserts cannot be

measured in the free state. The numbers are multiples of

the nominal thread size, or diameter, of the insert. The

actual insert lengths in the installed position are listed in

the insert selection tables. There they represent the

actual installed length plus 1/2 pitch.

Using the table below, an insert length can be selected

which will produce a thread system strong enough to

fracture a bolt before it will strip or damage either the

parent material or the insert.

Recommended Nominal Insert lengths Based on

Parent Material Versus Bolt Material Strengths

UNIFIED

Design Data

EXAMPLE: If parent material shear strength is 10KSI and the bolt tensile

strength is 54 KSI, the correct insert length is 2 diameters.

Shear Strength of

Parent Material

MPa(megapascals)

(Alum., Mag., Steel)

Bolt Ultimate Tensile Strength

MPa (megapascals)

300

1-1/2

1

1

1

1

1

1

70

100

150

200

250

300

350

400

2

1-1/2

1

1

1

1

1

500

2-1/2

1-1/2

1-1/2

1

1

1

1

600

2-1/2

2

1-1/2

1

1

1

1

800

–

2-1/2

2

1-1/2

1

1

1

1000

–

3

2

1-1/2

1-1/2

1-1/2

1

1200

–

–

2-1/2

2

1-1/2

1-1/2

1-1/2

1400

–

–

3

2-1/2

2

1-1/2

1-1/2

METRIC

Bolt Projection

Standard, readily available bolts and screws that require

no special hardware are used with CoilThread Inserts.

The bolt must engage the entire insert length to achieve

maximum assembly strength. To insure against partial

engagement, it is recommended that the tang always be

removed. This will also guarantee that the locking coil(s)

will be engaged by the full threads of the bolt. If design

parameters prevent this, contact the KATO Engineering

Department for assistance.

NOTES:

1. Bolt tensile strengths are specified minimums. When

choosing an insert length, consideration should be

given the maximum tensile strength allowed by the

bolt drawing or procurement

specification.

2. Service temperatures can cause significant variations

in strength values, therefore compensation should

be allowed.

3. The importance of shear values should be kept in

mind because the parent material is subject to shear

ing stress near the major diameter of the tapped

threads.

4. When the strength values fall between two values in

the table above, use next lower material shear value,

or the next higher bolt tensile strength value.

5. To achieve maximum strength, bolt length and thread

length as well as full tapped thread depth must be

sufficient to assure full thread engagement over the

entire length of the insert.

6. Specific charts detailing load values by thread size

are available: contact the KATO Engineering

Department.

Shear Strength

of Parent

Material (KSI)

Bolt Material Minimum

Ultimate Tensile Strength (KSI)

54 75 96 108 125 132 160 180 220

10

15

20

25

30

40

50

TANG

REMOVED

H DIM.

(MIN. TAP DEPTH

F DIM.

(MIN.

DRILLED

HOLE

DEPTH)

5

6

CoiLock Inserts exert a prevailing torque on male thread-

ed fasteners to prevent loosening due to vibration or

impact. They eliminate the need for other, less desirable

and costly locking mechanisms. They are excellent in

adjusting screw applications by preventing the male fas-

tener from creeping.

How CoiLock Inserts work

One or more of the coils in the insert have a series of

straight segments. Upon entry of the bolt these straight

segments are flexed outwardly, creating pressure on the

bolt. This pressure is applied between the flanks of the

bolt thread so that contact area is maximized and unit

pressure is minimized. It is often possible to realize cycle

life far in excess of specification requirements.

CoiLock Self-Locking Inserts – Tangless & Tanged

®

®

Location of Locking Coils

For 1, 1

1

/

2

, and 2 diameter lengths: The center of the lock-

ing coil (or coils) equals

1

/

2

the number of free coils. For

2

1

/

2

and 3 diameter lengths: The locking coil is located

the same distance from the tang as 2 diameter length

inserts. For Tangless inserts, the center of the locking

coil equals

1

/

2

the number of free coils.

Locking Torques

Unified size CoiLock Inserts conform to NASM21209

(Tanged) and NAS1130 (Tangless) and produce locking

torques in accordance with NASM8846 when used with

heat treated cadmium-plated bolts. When using heat

treated unplated or stainless steel bolts, an anti-seize

compound, e.g., molybdenum disulfide, must be used in

order to minimize galling and assure maximum cycle

life. Wear life of screw or bolt using CoiLock Inserts can

also be improved by specifying dry film lubrication or

cadmium plating.

KATO engineers are available for consultation on appli-

cations using brass or aluminum screws, low torque

adjusting screws and severe high torque requirements.

CoiLock inserts in Unified sizes are dyed red for easy

identification purposes only. It is alcohol soluble and can

be removed if desired. (Metric locking inserts are not

dyed red.)

COILOCK

SELF-LOCKING

INSERT

COILOCK

SELF-LOCKING

INSERT

POLYGONAL

COILTHREAD COIL

CIRCULAR,

STANDARD

COILTHREAD

COIL

CHEMICAL

COMPOUNDS

LOCK WASHER

SAFETY WIRE

CoiLock Self-Locking Inserts

eliminate the need for external

fastener locking components.

Locking coil segments exert prevailing

torque between the thread flanks of

the screw or bolt to resist loosening.

LOCK NUT

7

Min.

Locking Torque

15th Cycle

Max.

Locking

Torque

Nominal

Thread Size

Locking torque values for Metric CoilThread Inserts conform

to ISO2320, when tested in accordance with NASM8846.

For convenience these locking torque limits are shown above

in Newton-meters.

Locking torque values for Unified CoilThread Inserts conform

to NASM8846.

M2.2x0.45

M2.5x0.45

M3x0.5

M3.5x0.6

M4x0.7

M5x0.8

M6x1

M7x1

M8x1.25

M10x1.5

M12x1.75

M14x2

M16x2

M18x2.5

M20x2.5

M22x2.5

M24x3

0.14 N.m.

0.23 N.m.

0.45 N.m.

0.68 N.m.

0.9 N.m.

1.6 N.m.

3 N.m.

4.5 N.m.

6 N.m.

10.5 N.m.

15.5 N.m.

23 N.m.

31.5 N.m.

42 N.m.

54 N.m.

67.5 N.m.

80 N.m.

0.02 N.m.

0.05 N.m.

0.1 N.m.

0.12 N.m.

0.15 N.m.

0.3 N.m.

0.4 N.m.

0.6 N.m.

0.8 N.m.

1.4 N.m.

2.1 N.m.

3 N.m.

4.2 N.m.

5.5 N.m.

7 N.m.

9 N.m.

10.5 N.m

M8x1

M10x1

M10x1.25

M12x1.25

M12x1.5

M14x1.5

M16x1.5

M18x1.5

M20x1.5

M22x1.5

M18x2

M20x2

M22x2

M24x2

6 N.m.

10.5 N.m.

10.5 N.m.

15.5 N.m.

15.5 N.m.

23.5 N.m.

31.5 N.m.

42 N.m.

54 N.m.

67.5 N.m.

42 N.m.

54 N.m.

67.5 N.m.

80 N.m.

0.8 N.m.

1.4 N.m.

1.4 N.m.

2.1 N.m.

2.1 N.m.

3 N.m.

4.2 N.m.

5.5 N.m.

7 N.m.

9 N.m.

5.5 N.m.

7 N.m.

9 N.m.

10.5 N.m

Nominal

Thread Size

2 (.086)-56

3 (.099)-48

4 (.112)-40

5 (.125)-40

6 (.138)-32

8 (.164)-32

10 (.190)-24

12 (.216)-24

1/4 (.250)-20

5/16 (.3125)-18

3/8 (.3750)-16

7/16 (.4375)-14

1/2 (5000)-13

9/16 (.5625)-12

5/8 (.6250)-11

3/4 (.7500)-10

7/8 (8750)- 9

1 (1.0000)- 8

1-1/8 (1.1250)- 7

1-1/4 (1.2500)- 7

1-3/8 (1.3750)- 6

1-1/2 (1.5000)- 6

3 (.099)-56

4 (.112)-48

6 (.138)-40

8 (.164)- 36

10 (190)- 32

1/4 (.250)- 28

5/16 (.3125)- 24

3/8 (.3750)- 24

7/16 (.4375)- 20

1/2 (.5000)- 20

9/16 (.5625)- 18

5/8 (.6250)- 18

3/4 (.7500)- 16

7/8 (.8750)- 14

1 (1.0000)- 12

1-1/8 (1.1250)- 12

1-1/4 (1.2500)- 12

1-3/8 (1.3750)- 12

1-1/2 (1.5000)- 12

Max.

Locking

Torque

20 oz-in

32 oz-in

48 oz-in

75 oz-in

6 lb-in

9 lb-in

13 lb-in

24 lb-in

30 lb-in

60 lb-in

80 lb-in

100 lb-in

150 lb-in

200 lb-in

300 lb-in

400 lb-in

600 lb-in

800 lb-in

900 lb-in

1000 lb-in

1150 lb-in

1350 lb-in

32 oz-in

48 oz-in

6 lb-in

9 lb-in

13 lb-in

30 lb-in

60 lb-in

80 lb-in

100 lb-in

150 lb-in

200 lb-in

300 lb-in

400 lb-in

600 lb-in

800 lb-in

900 lb-in

1000 lb-in

1150 lb-in

1350 lb-in

Min.

Locking Torque

15th Cycle

3 oz-in

7 oz-in

10 oz-in

13 oz-in

1.0 lb-in

1.5 lb-in

2.0 lb-in

3.0 lb-in

4.5 lb-in

7.5 lb-in

12.0 lb-in

16.5 lb-in

24.0 lb-in

30.0 lb-in

40.0 lb-in

60.0 lb-in

82.0 lb-in

110.0 lb-in

137.0 lb-in

165.0 lb-in

185.0 lb-in

210.0 lb-in

7 oz-in

10 oz-in

1.0 lb-in

1.5 lb-in

2.0 lb-in

3.5 lb-in

6.5 lb-in

9.5 lb-in

14.0 lb-in

18.0 lb-in

24.0 lb-in

32.0 lb-in

50.0 lb-in

70.0 lb-in

90.0 lb-in

117.0 lb-in

143.0 lb-in

165.0 lb-in

190.0 lb-in

Unified Fine

Unified Coarse

Fine

Coarse

Torque Limits, Inch Torque Limits, Metric

To Convert From To Multiply By

N.m. oz-in 141.6119

N.m. lb-in 8.850748

oz-in N.m. 0.0070615

lb-in N.m. 0.1129848

Torque Units -Conversion Factors

8

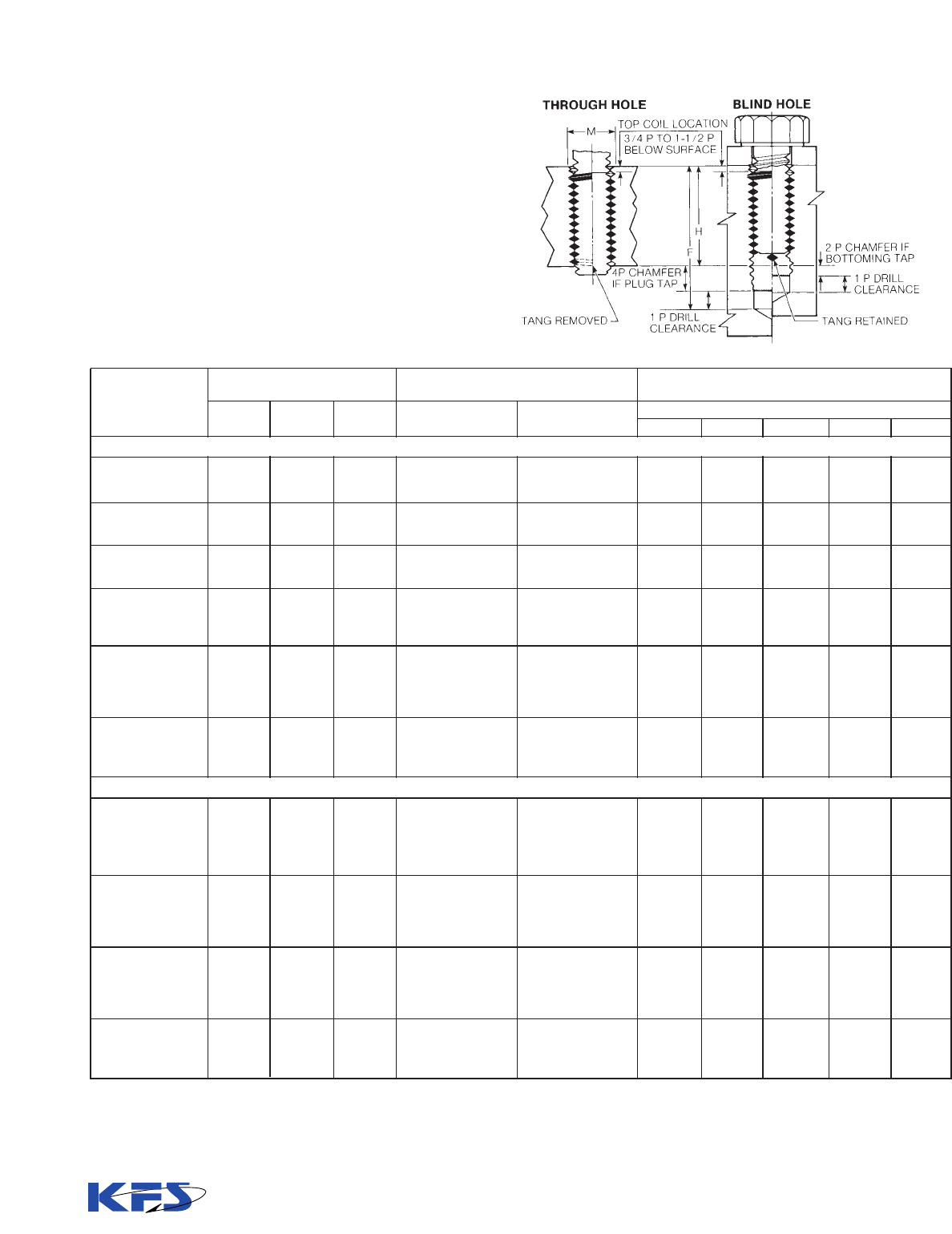

Drilling the Hole:

Drilled hole dimensions are tabulated on pages

10–13. The minor diameters tabulated conform to

NASM33537 (inch sizes), and MA1567 (metric sizes), and

must be met after tapping.

The drill sizes shown are recom-

mendations only, based on expected

material behavior and for increased

tap life in harder materials. Actual

individual conditions may require

varied drill sizes in order to produce

the correct minor diameter after

tapping.

The Minimum Drilled Hole Depth is designed to allow for:

1. The use of standard countersink as tabulated.

2. The use of standard Screw-Thread Insert (STI) plug or

bottoming tap for the maximum tool life.

3. The use of the standard installation set-down of 3/4 to 11/2

pitch below the work surface.

The “F” dimension minimum is based on installed insert

length, plus set-down, plus tap chamfer length, plus chip

clearance.

For plug taps with a nominal diameter of 5/16” or smaller the

“F” dimension minimum allows for a male center on the tap

equal in length to nominal tap diameter divided by 2.

Minimum Material Thickness for Through Holes:

The nominal insert length is the minimum through hole

length (material thickness) without counter-sinking and with

the insert located 1/4 to 1/2 pitch below the top surface. With

normal countersink and set-down, the minimum through

hole material thickness equals “H” dimension, the minimum

full thread depth...or minimum tapping depth shown tabulat-

ed on pages 10–13.

Edge Distance Minimum:

For most materials, a minimum edge distance equal to the

nominal bolt diameter may be used when measured from the

centerline of the hole.

Countersinking:

Countersinking dimensions are also tab-

ulated on Pages 11 and13. These con-

form to NASM33537 and MA1567.

Before tapping, it is good practice to

countersink 120° ± 5° to “M” diameter in

order to prevent a feather edge at the

start of the hole. The 60° per side coun-

tersink angle is used because it is the

same as the angles of the tapped thread, insert cross section

and inserting tool prewinder tip. This combination provides

for smooth and rapid production installation.

The “F” and “H” values are calculated with a

countersink depth of 1/2 pitch.

Tapping:

The pitch diameter limits shown tabulated

on pages 11 and 13 conform to

NASM33537 and MA1567 and must be

met in order to assure proper thread fit

after installation of the CoilThread Insert.

Installation Data –

Unified and Metric Sizes, Tanged & Tangless Inserts

Countersink with a

standard countersink.

Tap with KATO taps.

Drill with a standard

drill

CoilThread Inserts are normally installed

3/4 to 1-1/2 pitch below the surface of the

parent material in counter-sunk holes.

Modification of this set-down depth may

be made to suit certain limitations. Without

a countersink the inserts are typically

installed 1/4 to 1/2 pitch below the surface.

®

9

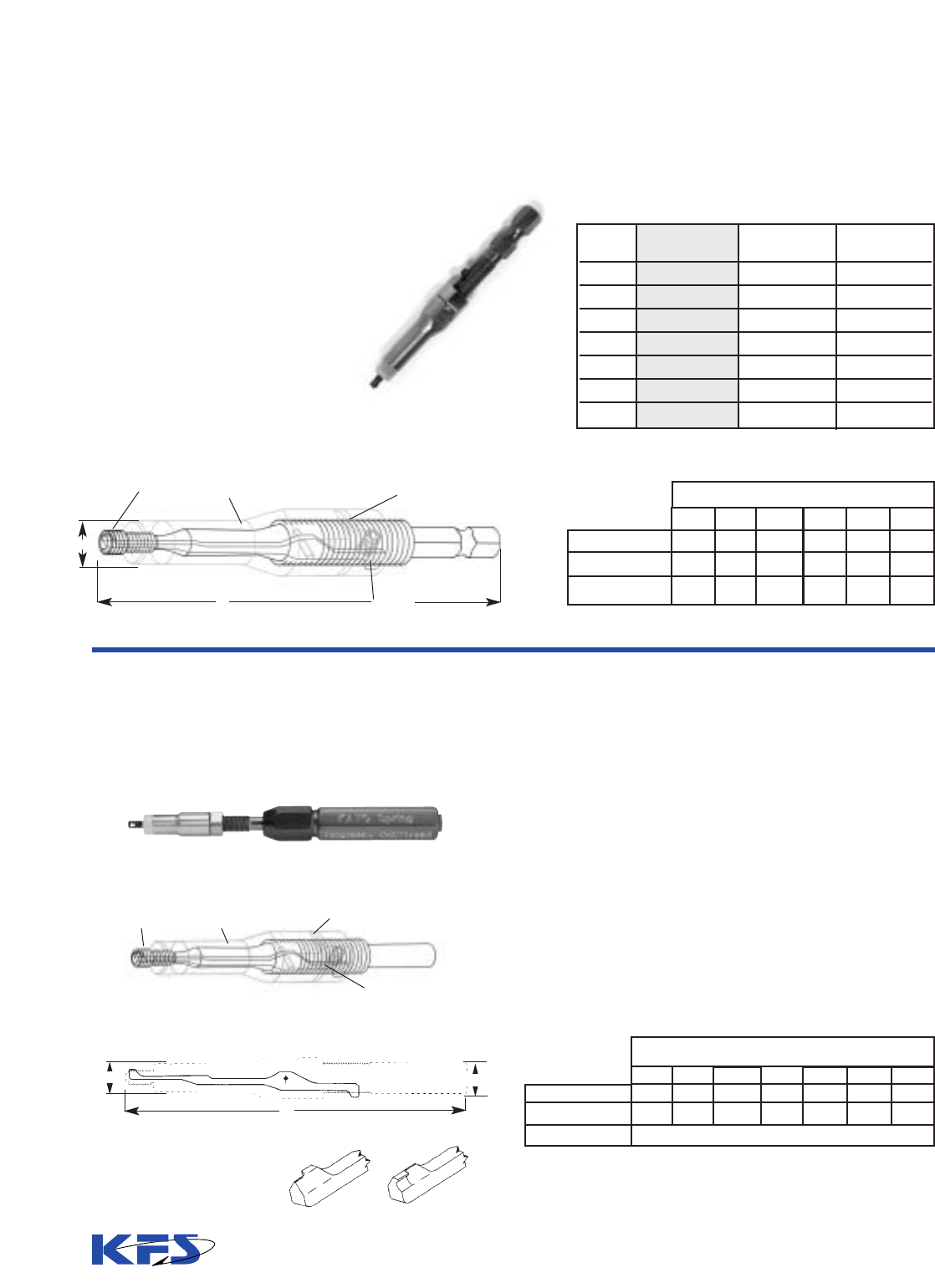

KATO STI Taps are for free machining materials. Four

styles are included see pages 14, 15, and 17):

1. Plug Style: Provides easy starting for through holes

and blind holes.

2. Bottoming Style: Ideal for blind holes that are drilled

to a minimum depth. Also for blind holes that require

threads to be close to the bottom of the hole.

3. Spiral Pointed Style (Plug): Free-cutting suited for

use in long through holes and in blind holes with

ample chip clearance.

4. Spiral Flute Style (Bottoming): Pulls chips out of

deep or blind holes in soft materials.

Roughing Taps are also available for use where tapping

operations are difficult. These reduce the load on the fin-

ishing tap. Contact KATO for availability.

As in drilling the tap “H” dimension limits are recommen-

dations only and may be varied where necessary to pro-

duce the required class of fit. CoilThread Inserts are iden-

tical for the various classes of fit. The class of fit is con-

trolled by the tapped hole tolerance.

The class of fit specifies the pitch diameter tolerance,

with 3B (inch) and 4H (metric) being the tighter ranges

and usually specified for military/aerospace applica-

tions. The tighter classes of fit are recommended when

using locking-type inserts for more consistent locking

torque. Class 2B (inch) and 5H (metric) tapped holes

provide a broader tolerance range, and are frequently

specified for commercial/industrial and thread repair

applications.

The minimum tap depth “H” dimension is calculated for use

of a standard countersink and standard insert set-down

depth. Modification of set-down or elimination of counter-

sink will permit a corresponding reduction in thread depth.

All tapped hole dimensions must be met after application of

any desired surface finish such as anodize.

Gaging:

KATO STI Plug Gages used to check the tapped holes are

described on pages 16 and 18.

Working gages are recommended for production use

since their greater tolerance allows for more wear.

Reference gages have pitch diameters at or very close to

basic size and are to be used as master gages.

Installation of the Tanged CoilThread Inserts:

CoilThread Inserts may be installed with tools conforming

to A-A-59158.

KATO tools for inserting, tang breakoff and insert extrac-

tion are also included on Pages 37-42 and 48-50.

The accuracy of the finished thread with the CoilThread

Insert installed depends upon the accuracy of the tapped

hole. If the tapped hole gages correctly, the installed

CoilThread Insert will be within the thread tolerance. No

further gaging is necessary. If gaging is attempted after

the CoilThread is installed, the GO thread plug gage may

not enter freely...however, the insert will seat itself when

the bolt or screw is installed and tightened. (Reference

NASM33537 and MA1567)

Tang Removal:

It is recommended that the tang always be removed to

insure that the full threads of the bolt fully engage the

locking coils when using CoiLock Inserts. To achieve max-

imum assembly strength the bolt must engage the entire

insert length.

Note: If necessary, CoilThread inserts can be removed

from their tapped holes even after tangs have been

removed. Removal tools are listed on pages 42 and 50.

Power Tools:

For rapid installation, KATO Power Tools are available.

These are detailed on Pages 38-41 and 49.

“No Go” (Hi) “Go”

With needle nose pliers With automatic tool

10

Installation Data -

Unified Sizes

Drilled Hole Dimensions

2 (.086)-56 .0899 .0961 .0961 3/32 (.0938) #41 (.0960) .236 .279 .322 .365 .408

3 (.099)-48 .1036 .1104 .1104 #36 (.1065) 7/64 (.1094) .273 .323 .372 .422 .471

4 (.112)-40 .1175 .1252 .1252 #31 (.1200) #31 (.1200) .318 .374 .430 .486 .542

5 (.125)-40 .1305 .1373 .1373 3.4mm (.1339) #29 (.1360) .338 .400 .462 .525 .588

6 (.138)-32 .1448 .1527 .1527 #26 (.1470) #25 (.1495) .394 .464 .532 .602 .670

8 (.164)-32 .1708 .1781 .1781 #17 (.1730) #16 (.1770) .434 .516 .598 .680 .762

10 (.190)-24 .1990 .2080 .2087 13/64 (.2031) #5 (.2055) .535 .630 .725 .820 .915

12 (.216)-24 .2250 .2340 .2347 #1 (.2280) #1 (.2280) .574 .682 .790 .898 1.006

1/ 4(.250)-20 .2608 .2704 .2723 H (.2660) H (.2660) .675 .800 .925 1.050 1.175

5/16 (.3125)-18 .3245 .3342 .3372 Q (.3320) Q (.3320) .801 .957 1.113 1.269 1.425

3/8 (.3750)-16 .3885 .3987 .4026 X (.3970) X (.3970) .750 .938 1.125 1.312 1.500

7/16 (.4375)-14 .4530 .4639 .4688 29/64 (.4531) 29/64 (.4531) .867 1.086 1.305 1.524 1.743

1/2 (.5000)-13* .5166 .5273 .5335 33/64 (.5156) 17/32 (.5312) .962 1.212 1.462 1.712 1.962

9/16 (.5625)-12* .5806 .5918 .5986 37/64 (.5781) 19/32 (.5938) 1.062 1.343 1.624 1.905 2.186

5/8 (.6250)-11 .6447 .6564 .6641 21/32 (.6562) 21/32 (.6562) 1.170 1.483 1.795 2.108 2.420

3/4 (.7500)-10 .7716 .7838 .7926 25/32 (.7812) 25/32 (.7812) 1.350 1.725 2.100 2.475 2.850

7/8 (.8750)- 9 .8990 .9119 .9213 29/32 (.9062) 29/32 (.9062) 1.542 1.979 2.417 2.854 3.292

1 (1.0000)- 8 1.0271 1.0421 1.0521 1-1/32 (1.0312) 1-1/32 (1.0312) 1.750 2.250 2.750 3.250 3.750

1- 1/8 (1.1250)- 7 1.1559 1.1730 1.1834 1-11/64 (1.1719) 1-11/64 (1.1719) 1.982 2.545 3.107 3.670 4.232

1- 1/4 (1.2500)- 7 1.2809 1.2980 1.3084 1-19/64 (1.2969) 1-19/64 (1.2969) 2.107 2.732 3.357 3.982 4.607

1- 3/8 (1.3750)- 6 1.4110 1.4310 1.4416 1-27/64 (1.4219) 1-27/64 (1.4219) 2.375 3.062 3.750 4.437 5.125

1- 1/2 (1.5000)- 6 1.5360 1.5560 1.5665 1-35/64 (1.5469) 1-35/64 (1.5469) 2.500 3.250 4.000 4.750 5.500

3 (.099)-56 .1029 .1086 .1086 #37 (.1040) #36 (.1065) .256 .305 .355 .404 .454

4 (.112)-48 .1166 .1229 .1229 3mm (.1181) #31 (.1200) .293 .349 .405 .461 .517

6 (.138)-40 .1435 .1503 .1503 #26 (.1470) #25 (.1495) .357 .426 .495 .564 .633

8 (.164)-36 .1701 .1771 .1771 #17 (.1730) #16 (.1770) .413 .495 .577 .659 .741

10 (.190)-32 .1968 .2041 .2041 #7 (.2010) 13/64 (.2031) .472 .568 .662 .758 .852

1/4 (.2500)-28 .2577 .2646 .2661 G (.2610) 6.7mm (.2638) .589 .714 .839 .964 1.089

5/16 (.3125)-24 .3215 .3288 .3312 21/64 (.3281) 21/64 (.3281) .718 .874 1.030 1.186 1.342

3/8 (.3750)-24 .3840 .3910 .3937 25/64 (.3906) 25/64 (.3906) .625 .812 1.000 1.187 1.375

7/16 (.4375)-20 .4483 .4561 .4593 29/64 (.4531) 29/64 (.4531) .738 .957 1.176 1.395 1.614

1/2 (.5000)-20 .5108 .5186 .5223 33/64 (.5156) 33/64 (.5156) .800 1.050 1.300 1.550 1.800

9/16 (.5625)-18 .5745 .5826 .5872 37/64 (.5781) 37/64 (.5781) .895 1.176 1.457 1.738 2.019

5/8 (.6250)-18 .6370 .6451 .6497 41/64 (.6406) 41/64 (.6406) .958 1.271 1.583 1.896 2.208

3/4 (.7500)-16 .7635 .7720 .7776 49/64 (.7656) 49/64 (.7655) 1.125 1.500 1.875 2.250 2.625

7/8 (.8750)-14 .8905 .8994 .9063 57/64 (.8906) 57/64 (.8906) 1.304 1.741 2.179 2.616 3.054

1 (1.0000)-12

1

1.0181 1.0281 1.0361 1-1/64 (1.0156) 1-1/32 (1.0312) 1.500 2.000 2.500 3.000 3.500

1-1/8 (1.1250)-12

1

1.1431 1.1531 1.1611 1-9/64 (1.1406) 1-5/32 (1.1562) 1.625 2.187 2.750 3.312 3.875

1-1/4 (1.2500)-12

1

1.2681 1.2781 1.2861 1-17/64 (1.2656) 1-9/32 (1.2812) 1.750 2.375 3.000 3.625 4.250

1-3/8 (1.3750)-12

1

1.3931 1.4031 1.4111 1-25/64 (1.3906) 1-13/32 (1.4062) 1.875 2.562 3.250 3.937 4.625

1-1/2 (1.5000)-12

1

1.5181 1.5281 1.5361 1-33/64 (1.5156) 1-17/32 (1.5312) 2.000 2.750 3.500 4.250 5.000

Unified Coarse

Unified Fine

Nominal

Thread Size

Minor Diameter

(After Tapping)

Suggested Drill Size

1

F Dim.

2

Minimum Drilling Depth for Taps

Min. All

Classes

Max Class

3B

Max Class

2B

Aluminum

Steel Magnesium

Plastic

11

1

/2 2

1

/2

32

Plug Taps

1

Standard size drills are suggested even though in these sizes they vary slightly from minor diameter specifications in NASM33537.

2

For plug taps with a nominal diameter of 5/16” or smaller, (F) minimum allows for a male center on the tap equal in length to nominal tap diameter divided by 2.

11

.157

.182

.212

.225

.263

.289

.357

.383

.450

.534

.625

.724

.808

.895

.989

1.150

1.319

1.500

1.696

1.821

2.042

2.167

.200

.232

.268

.288

.332

.371

.452

.491

.575

.690

.812

.943

1.058

1.176

1.301

1.525

1.757

2.000

2.259

2.446

2.729

2.917

.243

.281

.324

.350

.401

.453

.547

.599

.700

.846

1.000

1.162

1.308

1.457

1.614

1.900

2.194

2.500

2.821

3.071

3.417

3.667

.286

.331

.380

.412

.470

.535

.642

.707

.825

1.002

1.188

1.381

1.558

1.738

1.926

2.275

2.632

3.000

3.384

3.696

4.104

4.417

.329

.380

.436

.475

.539

.617

.737

.815

.950

1.158

1.375

1.600

1.808

2.019

2.239

2.650

3.069

3.500

3.946

4.321

4.792

5.167

.09

.11

.14

.16

.18

.20

.24

.26

.31

.38

.45

.52

.59

.66

.73

.87

1.00

1.14

1.29

1.41

1.56

1.69

.11

.14

.17

.19

.21

.23

.27

.29

.34

.41

.48

.55

.62

.69

.76

.90

1.03

1.17

1.32

1.44

1.59

1.72

.0976

.1126

.1283

.1413

.1583

.1843

.2170

.2430

.2825

.3486

.4156

.4839

.5499

.6167

.6841

.8149

.9471

1.0812

1.2178

1.3428

1.4832

1.6082

.0989

.1140

.1299

.1430

.1601

.1862

.2192

.2453

.2851

.3515

.4189

.4875

.5537

.6208

.6885

.8196

.9522

1.0890

1.2239

1.3490

1.4900

1.6151

.0996

.1148

.1306

.1438

.1611

.1872

.2203

.2464

.2863

.3529

.4203

.4890

.5554

.6225

.6903

.8216

.9543

1.0868

1.2262

1.3514

1.4926

1.6177

.10

.12

.14

.15

.17

.20

.23

.26

.30

.37

.44

.51

.58

.65

.72

.85

.99

1.13

1.27

1.39

1.54

1.67

.15

.17

.19

.21

.24

.28

.33

.37

.43

.53

.63

.73

.83

.93

1.03

1.23

1.42

1.63

1.83

2.02

2.23

2.42

.19

.22

.25

.28

.31

.36

.42

.47

.55

.68

.81

.95

1.08

1.21

1.34

1.60

1.86

2.13

2.39

2.64

2.92

3.17

.23

.27

.31

.34

.38

.44

.52

.58

.68

.84

1.00

1.17

1.33

1.49

1.65

1.98

2.30

2.63

2.96

3.27

3.60

3.92

.28

.32

.36

.40

.45

.52

.61

.69

.80

.99

1.19

1.38

1.58

1.77

1.97

2.35

2.74

3.13

3.52

3.89

4.29

4.67

.1117

.1289

.1473

.1603

.1817

.2077

.2475

.2735

.3187

.3884

.4602

.5343

.6042

.6751

.7477

.8850

1.0247

1.1681

1.3171

1.4421

1.5982

1.7232

.01786

.02083

.02500

.02500

.03125

.03125

.04167

.04167

.05000

.05556

.06250

.07143

.07692

.08333

.09091

.10000

.11111

.12500

.14286

.14286

.16667

.16667

.170

.195

.238

.275

.315

.393

.479

.542

.638

.700

.784

.847

1.000

1.161

1.333

1.458

1.583

1.708

1.833

.220

.251

.307

.357

.410

.518

.635

.729

.857

.950

1.065

1.160

1.375

1.598

1.833

2.021

2.208

2.396

2.583

.269

.307

.376

.439

.505

.643

.791

.917

1.076

1.200

1.346

1.472

1.750

2.036

2.333

2.583

2.833

3.083

3.333

.319

.363

.445

.521

.600

.768

.947

1.104

1.295

1.450

1.627

1.785

2.125

2.473

2.833

3.146

3.458

3.771

4.083

.368

.419

.514

.603

.695

.893

1.103

1.292

1.514

1.700

1.908

2.097

2.500

2.911

3.333

3.708

4.083

4.458

4.833

.11

.13

.17

.20

.23

.29

.36

.42

.50

.56

.63

.69

.82

.96

1.10

1.22

1.35

1.47

1.60

.14

.16

.20

.23

.26

.32

.39

.45

.53

.59

.66

.72

.85

.99

1.13

1.25

1.38

1.50

1.63

.1106

.1256

.1543

.1821

.2103

.2732

.3395

.4020

.4700

.5325

.5986

.6611

.7906

.9214

1.0542

1.1792

1.3042

1.4292

1.5542

.1119

.1271

.1560

.1840

.2123

.2754

.3421

.4047

.4731

.5357

.6020

.6646

.7945

.9257

1.0589

1.1841

1.3092

1.4343

1.5595

.1126

.1279

.1569

.1849

.2133

.2765

.3433

.4059

.4744

.5371

.6035

.6661

.7961

.9274

1.0608

1.1860

1.3112

1.4364

1.5615

.12

.13

.16

.19

.22

.29

.35

.42

.49

.55

.62

.68

.81

.95

1.08

1.21

1.33

1.46

1.58

.17

.19

.23

.27

.32

.41

.51

.60

.71

.80

.90

.99

1.19

1.38

1.58

1.77

1.96

2.15

2.33

.22

.24

.30

.36

.41

.54

.67

.79

.93

1.05

1.18

1.31

1.56

1.82

2.08

2.33

2.58

2.83

3.08

.27

.30

.37

.44

.51

.66

.82

.98

1.14

1.30

1.46

1.62

1.94

2.26

2.58

2.90

3.21

3.52

3.83

.31

.36

.44

.52

.60

.79

.98

1.17

1.36

1.55

1.74

1.93

2.31

2.70

3.08

3.46

3.83

4.21

4.58

.1247

.1419

.1733

.2032

.2337

.2995

.3700

.4325

.5062

.5687

.6384

.7009

.8352

.9718

1.1126

1.2376

1.3626

1.4876

1.6126

.01786

.02083

.02500

.02778

.03125

.03751

.04167

.04167

.05000

.05000

.05556

.05556

.06250

.07143

.08333

.08333

.08333

.08333

.08333

Unified Coarse

Unified Fine

F Dim

Minimum Drilling Depth for Taps

H Dim

Minimum Tapping Depth

Bottoming Taps

Countersink M

Diameter

(120°± 5° included angle)

Pitch Diameter

Diameter

11

1

/2

2

1

/2

3 Min.

Min.

3B

Max.

2B

Max.

Tap

Major

Dia.

Max.

Thread

Pitch

P

Max.211

1

/2

2

1

/2

32

Tapped Hole Dimensions-

Unified Sizes

M8x1 8.217 8.407 21/64 ( .3281) 21/64 ( .3281)

M10x1 10.217 10.407 Y ( .4040) 13/32 ( .4062)

M10x1.25

1

10.271 10.483 Y ( .4040) 13/32 ( .4062)

M12x1.25

1

12.271 12.483 31/64 ( .4844) 31/64 ( .4844)

M12x1.5

1

12.324 12.560 31/64 ( .4844) 1/2 ( .5000)

M14x1.5

1

14.324 14.560 9/16 ( .5625) 37/64 ( .5781)

M16x1.5

1

16.324 16.560 41/64 ( .6406) 21/32 ( .6562)

M18x1.5

1

18.324 18.560 23/32 ( .7188) 47/64 ( .7344)

M20x1.5

1

20.324 20.560 51/64 ( .7969) 13/16 ( .8125)

M22x1.5

1

22.324 22.560 7/8 ( .8750) 57/64 ( .8906)

M18x2 18.433 18.733 47/64 ( .7344) 47/64 ( .7344)

M20x2 20.433 20.733 13/16 ( .8125) 13/16 ( .8125)

M22x2 22.433 22.733 57/64 ( .8906) 57/64 ( .8906)

M24x2 24.433 24.733 31/32 ( .9688) 31/32 ( .9688)

12

Installation Data -

Metric Sizes

M2.2x0.45 2.297 2.397 #42 ( .0935) #42 ( .0935)

M2.5x0.45 2.597 2.697 #37 ( .1040) #37 ( .1040)

M3x0.5 3.108 3.220 1/8 ( .1250) 1/8 ( .1250)

M3.5x0.6 3.630 3.755 #27 ( .1440) #26 ( .1470)

M4x0.7 4.152 4.292 #19 ( .1660) #19 ( .1660)

M5x0.8 5.174 5.344 # 5 ( .2055) # 4 ( .2090)

M6x1 6.217 6.407 D ( .2460) 1/4 ( .2500)

M7x1 7.217 7.407 L ( .2900) L ( .2900)

M8x1.25 8.271 8.483 21/64 ( .3281) Q ( .3320)

M10x1.5 10.324 10.560 Z ( .4130) Z ( .4130)

M12x1.75

1

12.379 12.644 31/64 ( .4844) 1/2 ( .5000)

M14x2 14.433 14.733 37/64 ( .5781) 37/64 ( .5781)

M16x2 16.433 16.733 21/32 ( .6562) 21/32 ( .6562)

M18x2.5 18.541 18.896 47/64 ( .7344) 47/64 ( .7344)

M20x2.5 20.541 20.896 13/16 ( .8125) 13/16 ( .8125)

M22x2.5 22.541 22.896 57/64 ( .8906) 57/64 ( .8906)

M24x3 24.649 25.049 63/64 ( .9844) 63/64 ( .9844)

Nominal Thread

Size

Minor Diameter

Suggested Drill Size (Inch)

1, 2

Steel Magnesium

Plastic

Minimum

Maximum

Aluminum

Notes:

1

Standard size drills are suggested even though some sizes may vary slightly from the specified minor diameter limits.

2

Metric size drills may be substituted, provided they fall within the minor diameter limits.

3

For plug taps with a nominal diameter of M8 or smaller, (F) minimum allows for a male center on the tap equal in length to

nominal tap diameter divided by 2.

4

Dimensions shown are in millimeters (mm).

Plug Taps

6.00 7.10 8.20 9.30 10.40

6.45 7.70 8.95 10.20 11.45

7.50 9.00 10.50 12.00 13.50

8.85 10.60 12.35 14.10 15.85

10.20 12.20 14.20 16.20 18.20

12.30 14.80 17.30 19.80 22.30

15.00 18.00 21.00 24.00 27.00

16.50 20.00 23.50 27.00 30.50

19.50 23.50 27.50 31.50 35.50

19.00 24.00 29.00 34.00 39.00

22.50 28.50 34.50 40.50 46.50

26.00 33.00 40.00 47.00 54.00

28.00 36.00 44.00 52.00 60.00

33.00 42.00 51.00 60.00 69.00

35.00 45.00 55.00 65.00 75.00

37.00 48.00 59.00 70.00 81.00

42.00 54.00 66.00 78.00 90.00

18.00 22.00 26.00 30.00 34.00

16.00 21.00 26.00 31.00 36.00

17.50 22.50 27.50 32.50 37.50

19.50 25.50 31.50 37.50 43.50

21.00 27.00 33.00 39.00 45.00

23.00 30.00 37.00 44.00 51.00

25.00 33.00 41.00 49.00 57.00

27.00 36.00 45.00 54.00 63.00

29.00 39.00 49.00 59.00 69.00

31.00 42.00 53.00 64.00 75.00

30.00 39.00 48.00 57.00 66.00

32.00 42.00 52.00 62.00 72.00

34.00 45.00 56.00 67.00 78.00

36.00 48.00 60.00 72.00 84.00

1

1

1

/

2 2 2

1

/

2 3

F Dim.

3

Minimum Drilling Depth for Taps

Coarse Series

Fine Series

13

Tapped Hole Dimensions -

Metric Sizes

F Dim

Minimum Drilling Depth for Taps

Bottoming Taps

11

1

/2

22

1

/2

3

4.00 5.10 6.20 7.30 8.40

4.30 5.55 6.80 8.05 9.30

5.00 6.50 8.00 9.50 11.00

5.90 7.65 9.40 11.15 12.90

6.80 8.80 10.80 12.80 14.80

8.20 10.70 13.20 15.70 18.20

10.00 13.00 16.00 19.00 22.00

11.00 14.50 18.00 21.50 25.00

13.00 17.00 21.00 25.00 29.00

16.00 21.00 26.00 31.00 36.00

19.00 25.00 31.00 37.00 43.00

22.00 29.00 36.00 43.00 50.00

24.00 32.00 40.00 48.00 56.00

28.00 37.00 46.00 55.00 64.00

30.00 40.00 50.00 60.00 70.00

32.00 43.00 54.00 65.00 76.00

36.00 48.00 60.00 72.00 84.00

12.00 16.00 20.00 24.00 28.00

14.00 19.00 24.00 29.00 34.00

15.00 20.00 25.00 30.00 35.00

17.00 23.00 29.00 35.00 41.00

18.00 24.00 30.00 36.00 42.00

20.00 27.00 34.00 41.00 48.00

22.00 30.00 38.00 46.00 54.00

24.00 33.00 42.00 51.00 60.00

26.00 36.00 46.00 56.00 66.00

28.00 39.00 50.00 61.00 72.00

26.00 35.00 44.00 53.00 62.00

28.00 38.00 48.00 58.00 68.00

30.00 41.00 52.00 63.00 74.00

32.00 44.00 56.00 68.00 80.00

2.90 2.40 2.492 2.532 2.547 2.7 3.8 4.9 6.0 7.1 2.845

3.40 2.90 2.792 2.832 2.847 3.0 4.2 5.5 6.7 8.0 3.145

4.00 3.40 3.325 3.367 3.384 3.5 5.0 6.5 8.0 9.5 3.716

4.70 4.10 3.890 3.940 3.959 4.1 5.9 7.6 9.4 11.1 4.354

5.30 4.70 4.455 4.509 4.529 4.7 6.7 8.7 10.7 12.7 5.007

6.40 5.80 5.520 5.577 5.597 5.8 8.3 10.8 13.3 15.8 6.145

7.70 7.10 6.650 6.719 6.742 7.0 10.0 13.0 16.0 19.0 7.422

8.70 8.10 7.650 7.719 7.742 8.0 11.5 15.0 18.5 22.0 8.422

10.10 9.50 8.812 8.886 8.911 9.3 13.3 17.3 21.3 25.3 9.787

12.40 11.80 10.974 11.061 11.089 11.5 16.5 21.5 26.5 31.5 12.131

14.80 14.20 13.137 13.236 13.271 13.8 19.8 25.8 31.8 37.8 14.478

17.10 16.50 15.299 15.406 15.444 16.0 23.0 30.0 37.0 44.0 16.822

19.10 18.50 17.299 17.406 17.444 18.0 26.0 34.0 42.0 50.0 18.822

21.80 21.20 19.624 19.738 19.778 20.5 29.5 38.5 47.5 56.5 21.513

23.80 23.20 21.624 21.738 21.778 22.5 32.5 42.5 52.5 62.5 23.513

25.80 25.20 23.624 23.738 23.778 24.5 35.5 46.5 57.5 68.5 25.513

28.50 27.90 25.948 26.093 26.135 27.0 39.0 51.0 63.0 75.0 28.238

Countersink M

Diameter

(120°± 5° included

angle)

Pitch Diameter

H Dim

Minimum Tapping Depth

Diameter (mm)

Tap

Major

Dia.

Max.

Max.

2

1

1

/2

1

5H

Max.

4H

Max.

Min.

Min.

3

2

1

/2

9.70 9.10 8.650 8.719 8.742 9.0 13.0 17.0 21.0 25.0 9.422

11.70 11.10 10.650 10.719 10.742 11.0 16.0 21.0 26.0 31.0 11.422

12.10 11.50 10.812 10.886 10.911 11.3 16.3 21.3 26.3 31.3 11.787

14.10 13.50 12.812 12.898 12.926 13.3 19.3 25.3 31.3 37.3 13.787

14.40 13.80 12.974 13.067 13.099 13.5 19.5 25.5 31.5 37.5 14.131

16.40 15.80 14.974 15.067 15.099 15.5 22.5 29.5 36.5 43.5 16.131

18.40 17.80 16.974 17.067 17.099 17.5 25.5 33.5 41.5 49.5 18.131

20.40 19.80 18.974 19.067 19.099 19.5 28.5 37.5 46.5 55.5 20.131

22.40 21.80 20.974 21.067 21.099 21.5 31.5 41.5 51.5 61.5 22.131

24.40 23.80 22.974 23.067 23.099 23.5 34.5 45.5 56.5 67.5 24.131

21.10 20.50 19.299 19.406 19.444 20.0 29.0 38.0 47.0 56.0 20.822

23.10 22.50 21.299 21.406 21.444 22.0 32.0 42.0 52.0 62.0 22.822

25.10 24.50 23.299 23.406 23.444 24.0 35.0 46.0 57.0 68.0 24.822

27.10 26.50 25.299 25.414 25.454 26.0 38.0 50.0 62.0 74.0 26.822

Fine Series

Coarse Series

2 (.086)-56

3 (.099)-48

4 (.112)-40

5 (.125)-40

6 (.138)-32

8 (.164)-32

10 (.190)-24

12 (.216)-24

1/4 (.250)-20

5/16 (.3125)-18

3/8 (.3750)-16

7/16 (.4375)-14

1/2 (.5000)-13

9/16 (.5625)-12

5/8 (.6250)-11

3/4 (.7500)-10

7/8 (.8750)- 9

1 (1.000)- 8

02SRP-H1

03SRP-H1

04SRP-H1

3SFB-H3

1SFB-H3

4SFB-H3

3SFB-H2

1SFB-H2

4SFB-H2

3SPP-H3

1SPP-H3

4SPP-H3

3SPP-H2

1SPP-H2

4SPP-H2

3SRB-H3

1SRB-H3

4SRB-H3

3SRB-H2

1SRB-H2

4SRB-H2

3SRP-H3

1SRP-H3

4SRP-H3

5SRP-H3

6SRP-H3

7SRP-H3

8SRP-H3

3SRP-H2

1SRP-H2

4SRP-H2

05SRP-H1

06SRP-H2

2SRP-H2

05SFB-H2

06SFB-H3

2SFB-H3

05SFB-H1

06SFB-H2

2SFB-H2

02SFB-H2

03SFB-H2

04SFB-H2

02SFB-H1

03SFB-H1

04SFB-H1

05SPP-H2

06SPP-H3

2SPP-H3

02SPP-H2

03SPP-H2

04SPP-H2

05SPP-H1

06SPP-H2

2SPP-H2

02SPP-H1

03SPP-H1

04SPP-H1

05SRB-H2

06SRB-H3

2SRB-H3

02SRB-H2

03SRB-H2

04SRB-H2

02SRB-H1

03SRB-H1

04SRB-H1

02SRP-H2

03SRP-H2

04SRP-H2

05SRB-H1

06SRB-H2

2SRB-H2

05SRP-H2

06SRP-H3

2SRP-H3

5SPP-H3

6SPP-H3

7SPP-H3

8SPP-H3

5SRB-H4

6SRB-H4

7SRB-H4

8SRB-H4

5SPP-H4

6SPP-H4

7SPP-H4

8SPP-H4

5SFB-H3

6SFB-H3

7SFB-H3

8SFB-H3

5SFB-H4

6SFB-H4

7SFB-H4

8SFB-H4

5SRB-H3

6SRB-H3

7SRB-H3

8SRB-H3

5SRP-H4

6SRP-H4

7SRP-H4

8SRP-H4

9SRP-H3

10SRP-H3

12SRP-H3

14SRP-H3

16SRP-H4

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

9SRB-H4

10SRB-H4

12SRB-H5

14SRB-H5

16SRB-H6

9SRB-H3

10SRB-H3

12SRB-H3

14SRB-H3

16SRB-H4

9SRP-H4

10SRP-H4

12SRP-H5

14SRP-H5

16SRP-H6

Nominal

Thread

Size

Standard Regular Finishing

Plug

Bottoming Plug Bottoming

Spiral Pointed

Spiral Flute

3B

3B

3B

3B

2B 2B

2B

2B

Unified Coarse

Unified Fine

3 (.099)-56

4 (.112)-48

6 (.138)-40

8 (.164)-36

10 (.190)-32

1/4 (.2500)-28

5/16 (.3125)-24

3/8 (.3750)-24

7/16 (.4375)-20

1/2 (.5000)-20

9/16 (.5625)-18

5/8 (.6250)-18

3/4 (.7500)-16

7/8 (.8750)-14

1 (1.000)-12

03SRP-H1

04SRP-H1

06SRP-H1

2SRP-H1

3SRP-H2

03SRP-H2

04SRP-H2

06SRP-H2

2SRP-H2

3SRP-H3

03SRB-H1

04SRB-H1

06SRB-H1

2SRB-H1

3SRB-H2

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

9SRB-H4

10SRB-H4

12SRB-H4

14SRB-H4

161SRB-H6

9SRB-H3

10SRB-H3

12SRB-H3

14SRB-H3

161SRB-H4

9SRP-H4

10SRP-H4

12SRP-H4

14SRP-H4

161SRP-H6

9SRP-H3

10SRP-H3

12SRP-H3

14SRP-H3

161SRP-H4

03SFB-H2

04SFB-H2

06SFB-H2

2SFB-H2

3SFB-H2

4SFB-H3

5SFB-H3

6SFB-H3

7SFB-H4

8SFB-H4

4SFB-H2

5SFB-H2

6SFB-H2

7SFB-H3

8SFB-H3

4SPP-H3

5SPP-H3

6SPP-H3

7SPP-H4

8SPP-H4

4SPP-H2

5SPP-H2

6SPP-H2

7SPP-H3

8SPP-H3

4SRB-H3

5SRB-H3

6SRB-H3

7SRB-H4

8SRB-H4

4SRB-H2

5SRB-H2

6SRB-H2

7SRB-H3

8SRB-H3

4SRP-H3

5SRP-H3

6SRP-H3

7SRP-H4

8SRP-H4

4SRP-H2

5SRP-H2

6SRP-H2

7SRP-H3

8SRP-H3

03SFB-H1

04SFB-H1

06SFB-H1

2SFB-H1

3SFB-H2

03SPP-H2

04SPP-H2

06SPP-H2

2SPP-H2

3SPP-H3

03SPP-H1

04SPP-H1

06SPP-H1

2SPP-H1

3SPP-H2

03SRB-H2

04SRB-H2

06SRB-H2

2SRB-H2

3SRB-H3

14

Plug Style

(4-Thread

Chamfer)

Bottoming Style

(2-Thread

Chamfer)

Spiral Pointed

Taps – Plug

(4-Thread

Chamfer)

Spiral Flute Taps

– Bottoming

(2-Thread

Chamfer)

CoilThread STI Taps – Unified Thread Sizes

(For free machining materials)

For general hand and machine operations.

To order, add the pr

efix CTC- to all Unified Coarse part numbers tabulated, and add CTF- to all Unified Fine part

numbers. Example: CTC-02SRP-H1.

Easy

starting for

through-holes and

blind holes.

Ideal for

blind holes

that are drilled to

a minimum depth.

Free-

cutting for

use in long

through-holes

and in blind holes

with chip clearance.

Pulls chips

out of deep or

blind holes in soft

materials.

Provide chip disposal in tapping operations.

The“H” limit number (last digit in Part Numbers above) indicates the number of .0005 inch increments the tap’s maximum pitch diameter is above the

basic (minimum).

The Class of Fit specifies the pitch diameter tolerance of the tapped hole, with 3B being the tighter range usually specified in military/aero-

space applications, and when consistent locking torque is desired when using locking inserts. Class 2B taps provide a broader tolerance range

or looser fit, and are normally specified in commercial/industrial applications. The class of fit of the installed insert is controlled by the class

of fit of the tap.

STI Tap Dimensions – Unified Sizes

Nominal

Thread

Size

2 (.086)-56

3 (.099)-48

4 (.112)-40

5 (.125)-40

6 (.138)-32

8 (.164)-32

10 (.190)-24

12 (.216)-24

1/4 (.250)-20

5/16 (.3125)-18

3/8 (.3750)-16

7/16 (.4375)-14

1/2 (.5000)-13

9/16 (.5625)-12

5/8 (.6250)-11

3/4 (.7500)-10

7/8 (.8750)- 9

1 (1.0000)- 8

3 (.099)-56

4 (.112)-48

6 (.138)-40

8 (.164)-36

10 (.190)-32

1/4 (.2500)-28

5/16 (.3125)-24

3/8 (.3750)-24

7/16 (.4375)-20

1/2 (.5000)-20

9/16 (.5625)-18

5/8 (.6250)-18

3/4 (.7500)-16

7/8 (.8750)-14

1 (1.0000)-12

Length

Overall

A

1-7/8

1-15/16

2

2-1/8

2-3/8

2-3/8

2-1/2

2-23/32

2-23/32

2-15/16

3-3/8

3-19/32

3-13/16

4-1/32

4-1/4

4-11/16

5-1/8

5-3/4

1-15/16

2

2-1/8

2-3/8

2-1/2

2-23/32

2-15/16

3-5/32

3-3/8

3-19/32

3-13/16

4-1/32

4-15/32

5-1/8

5-7/16

Length of

Thread

B

9/16

5/8

11/16

3/4

7/8

15/16

1

1-1/8

1-1/8

1-1/4

1-21/32

1-21/32

1-13/16

1-13/16

2

2-7/32

2-1/2

2-9/16

5/8

11/16

3/4

15/16

1

1-1/8

1-1/4

1-7/16

1-21/32

1-21/32

1-13/16

1-13/16

2

2-1/2

2-9/16

Style

*

1

1

1

1

1

1

2

2

2

2

3

3

3

3

3

3

3

3

1

1

1

1

2

2

3

3

3

3

3

3

3

3

3

Spiral

Flute Bott.

2

2

2

3

3

3

3

3

3

3

3

4

4

__

__

__

__

__

2

2

3

3

3

3

3

3

3

4

__

__

__

__

__

Spiral

Point Plug

2

2

2

2

2

2

2

2

2

3

3

3

3

__

__

__

__

__

2

2

2

2

2

2

3

3

3

3

__

__

__

__

__

Hand

Finishing

Plug & Bott.

3

3

3

3

3

3

3

3

3

4

4

4

4

4

4

4

4

4

3

3

3

3

3

3

4

4

4

4

4

4

4

4

4

Size of

Square

.110

.110

.110

.131

.152

.165

.191

.238

.238

.286

.275

.322

.360

.406

.442

.523

.600

.766

.110

.110

.131

.165

.191

.238

.286

.242

.275

.322

.360

.406

.489

.600

.672

Dia. of

Shank

D

.141

.141

.141

.168

.194

.220

.255

.318

.318

.381

.367

.429

.480

.542

.590

.697

.800

1.021

.141

.141

.168

.220

.255

.318

.381

.323

.367

.429

.480

.542

.652

.800

.896

Length

of Square

C

3/16

3/16

3/16

1/4

1/4

9/32

5/16

3/8

3/8

7/16

7/16

1/2

9/16

5/8

11/16

3/4

13/16

1

3/16

3/16

1/4

9/32

5/16

3/8

7/16

13/32

7/16

1/2

9/16

5/8

11/16

13/16

7/8

Tap Dimensions Number of Flutes

Unified Fine

Unified Coarse

Style 1 Thread Length

Includes Chamfer

Style 2 Thread Length

Includes Chamfer

Style 3 Thread Length

Includes Chamfer

* All bottoming taps have male center on thread end removed.

15

16

STI Thread Plug Gages – Unified Sizes

KATO STI Thread Plug Gages are used to

check the accuracy of the tapped hole. If

the tapped hole is correct, the finished

thread will also be accurate when the

insert is installed. It is not necessary to

gage the installed insert.

You will note that both “Working Gages”

and “Reference Gages” are shown tabu-

lated. Working Gages are recommended

for use with production since their

greater tolerance allows for more wear.

Reference Gages have pitch diameters at

or very close to basic sizes and are to be

used as master gages.

NOTES:

1. The Working Gage “GO”

member has a .0002 wear

allowance on the pitch diameter.

2. Gaging of the tapped thread is

specified because a standard

gage may not freely enter an

installed insert. The insert will

seat itself once a bolt or screw

is installed and tightened.

(REF. NASM33537.)

3. KATO STI Gages comply with

A-A-59158.

4. The “GO” member checks basic

pitch diameters, major diameter

minimum and lead. The “HI”

member checks maximum pitch

diameter. Minor diameter is

checked separately with a grad-

uated pin set, for example.

Nominal

Thread

Size

2 (.086)-56

3 (.099)-48

4 (.112)-40

5 (.125)-40

6 (.138)-32

8 (.164)-32

10 (.190)-24

12 (.216)-24

1/4 (.250)-20

5/16 (.3125)-18

3/8 (.3750)-16

7/16 (.4375)-14

1/2 (.5000)-13

9/16 (.5625)-12

5/8 (.6250)-11

3/4 (.7500)-10

7/8 (.8750)- 9

1 (1.0000)- 8

3 (.099)-56

4 (.112)-48

6 (.138)-40

8 (.164)- 36

10 (.190)- 32

1/4 (.250)- 28

5/16 (.3125)- 24

3/8 (.3750)- 24

7/16 (.4375)- 20

1/2 (.5000)- 20

9/16 (.5625)- 18

5/8 (.6250)- 18

3/4 (.7500)- 16

7/8 (.8750)- 14

1 (1.0000)- 12

3B

CGC-02X-3B

CGC-03X-3B

CGC-04X-3B

CGC-05X-3B

CGC-06X-3B

CGC-2X-3B

CGC-3X-3B

CGC-1X-3B

CGC-4X-3B

CGC-5X-3B

CGC-6X-3B

CGC-7X-3B

CGC-8X-3B

__

__

__

__

__

CGF-03X-3B

CGF-04X-3B

CGF-06X-3B

CGF-2X-3B

CGF-3X-3B

CGF-4X-3B

CGF-5X-3B

CGF-6X-3B

CGF-7X-3B

CGF-8X-3B

__

__

__

__

__

2B

CGC-02X-2B

CGC-03X-2B

CGC-04X-2B

CGC-05X-2B

CGC-06X-2B

CGC-2X-2B

CGC-3X-2B

CGC-1X-2B

CGC-4X-2B

CGC-5X-2B

CGC-6X-2B

CGC-7X-2B

CGC-8X-2B

__

__

__

__

__

CGF-03X-2B

CGF-04X-2B

CGF-06X-2B

CGF-2X-2B

CGF-3X-2B

CGF-4X-2B

CGF-5X-2B

CGF-6X-2B

CGF-7X-2B

CGF-8X-2B

__

__

__

__

__

2B

CGC-02W-2B

CGC-03W-2B

CGC-04W-2B

CGC-05W-2B

CGC-06W-2B

CGC-2W-2B

CGC-3W-2B

CGC-1W-2B

CGC-4W-2B

CGC-5W-2B

CGC-6W-2B

CGC-7W-2B

CGC-8W-2B

CGC-9W-2B

CGC-10W-2B

CGC-12W-2B

CGC-14W-2B

CGC-16W-2B

CGC-03W-2B

CGC-04W-2B

CGC-06W-2B

CGC-2W-2B

CGC-3W-2B

CGC-4W-2B

CGC-5W-2B

CGC-6W-2B

CGC-7W-2B

CGC-8W-2B

CGC-9W-2B

CGC-10W-2B

CGC-12W-2B

CGC-14W-2B

CGC-161W-2B

3B

CGC-02W-3B

CGC-03W-3B

CGC-04W-3B

CGC-05W-3B

CGC-06W-3B

CGC-2W-3B

CGC-3W-3B

CGC-1W-3B

CGC-4W-3B

CGC-5W-3B

CGC-6W-3B

CGC-7W-3B

CGC-8W-3B

CGC-9W-3B

CGC-10W-3B

CGC-12W-3B

CGC-14W-3B

CGC-16W-3B

CGF-03W-3B

CGF-04W-3B

CGF-06W-3B

CGF-2W-3B

CGF-3W-3B

CGF-4W-3B

CGF-5W-3B

CGF-6W-3B

CGF-7W-3B

CGF-8W-3B

CGF-9W-3B

CGF-10W-3B

CGF-12W-3B

CGF-14W-3B

CGF-161W-3B

Working Gages Reference Gages

Unified Fine

Unified Coarse

KATO STI Gage

with GO and HI

members.

17

M2.2x0.45

M2.5x0.45

M3x0.5

M3.5x0.6

M4x0.7

M5x0.8

M6x1

M7x1

M8x1.25

M10x1.5

M12x1.75

M14x2

M16x2

M18x2.5

M20x2.5

M22x2.5

M24x3

CTM-2.2x.45SRP-4H

CTM-2.5x.45SRP-4H

CTM-3x.5SRP-4H

CTM-3.5x.6SRP-4H

CTM-4x.7SRP-4H

CTM-5x.8SRP-4H

CTM-6x1SRP-4H

CTM-7x1SRP-4H

CTM-8x1.25SRP-4H

CTM-10x1.5SRP-4H

CTM-12x1.75SRP-4H

CTM-14x2SRP-4H

CTM-16x2SRP-4H

CTM-18x2.5SRP-4H

CTM-20x2.5SRP-4H

CTM-22x2.5SRP-4H

CTM-24x3SRP-4H

CTM-2.2x.45SRB-4H

CTM-2.5x.45SRB-4H

CTM-3x.5SRB4H

CTM-3.5x.6SRB-4H

CTM-4x.7SRB-4H

CTM-5x.8SRB-4H

CTM-6x1SRB-4H

CTM-7x1SRB-4H

CTM-8x1.25SRB-4H

CTM-10x1.5SRB-4H

CTM-12x1.75SRB-4H

CTM-14x2SRB-4H

CTM-16x2SRB-4H

CTM-18x2.5SRB-4H

CTM-20x2.5SRB-4H

CTM-22x2.5SRB-4H

CTM-24x3SRB-4H

CTM-2.2x.45SPP-4H

CTM-2.5x.45SPP-4H

CTM-3x.5SPP-4H

CTM-3.5x.6SPP-4H

CTM-4x.7SPP-4H

CTM-5x.8SPP-4H

CTM-6x1SPP-4H

CTM-7x1SPP-4H

CTM-8x1.25SPP-4H

CTM-10x1.5SPP-4H

CTM-12x1.75SPP-4H

CTM-14x2SPP-4H

CTM-16x2SPP-4H

CTM-18x2.5SPP-4H

CTM-20x2.5SPP-4H

CTM-22x2.5SPP-4H

CTM-24x3SPP-4H

CTM-2.2x.45SPP-5H

CTM-2.5x.45SPP-5H

CTM-3x.5SPP-5H

CTM-3.5x.6SPP-5H

CTM-4x.7SPP-5H

CTM-5x.8SPP-5H

CTM-6x1SPP-5H

CTM-7x1SPP-5H

CTM-8x1.25SPP-5H

CTM-10x1.5SPP-5H

CTM-12x1.75SPP-5H

CTM-14x2SPP-5H

CTM-16x2SPP-5H

CTM-18x2.5SPP-5H

CTM-20x2.5SPP-5H

CTM-22x2.5SPP-5H

CTM-24x3SPP-5H

CTM-2.2x.45SRP-5H

CTM-2.5x.45SRP-5H

CTM-3x.5SRP-5H

CTM-3.5x.6SRP-5H

CTM-4x.7SRP-5H

CTM-5x.8SRP-5H

CTM-6x1SRP-5H

CTM-7x1SRP-5H

CTM-8x1.25SRP-5H

CTM-10x1.5SRP-5H

CTM-12x1.75SRP-5H

CTM-14x2SRP-5H

CTM-16x2SRP-5H

CTM-18x2.5SRP-5H

CTM-20x2.5SRP-5H

CTM-22x2.5SRP-5H

CTM-24x3SRP-5H

CTM-2.2x.45SRB-5H

CTM-2.5x.45SRB-5H

CTM-3x.5SRB-5H

CTM-3.5x.6SRB-5H

CTM-4x.7SRB-5H

CTM-5x.8SRB-5H

CTM-6x1SRB-5H

CTM-7x1SRB-5H

CTM-8x1.25SRB-5H

CTM-10x1.5SRB-5H

CTM-12x1.75SRB-5H

CTM-14x2SRB-5H

CTM-16x2SRB-5H

CTM-18x2.5SRB-5H

CTM-20x2.5SRB-5H

CTM-22x2.5SRB-5H

CTM-24x3SRB-5H

Nominal

Thread

Size

Plug Style

(4-Thread

Chamfer)

Bottoming Style

(2-Thread

Chamfer)

Standard Regular Finishing

Plug

Bottoming

Plug

Spiral Pointed

4H

4H

4H

5H

5H

5H

Coarse

Fine

M8x1

M10x1

M10x1.25

M12x1.25

M12x1.5

M14x1.5

M16x1.5

M18x1.5

M20x1.5

M22x1.5

M18x2

M20x2

M22x2

M24x2

CTM-8x1SRP-4H

CTM-10x1SRP-4H

CTM-10x1.25SRP-4H

CTM-12x1.25SRP-4H

CTM-12x1.5SRP-4H

CTM-14x1.5SRP-4H

CTM-16x1.5SRP-4H

CTM-18x1.5SRP-4H

CTM-20x1.5SRP-4H

CTM-22x1.5SRP-4H

CTM-18x2SRP-4H

CTM-20x2SRP-4H

CTM-22x2SRP-4H

CTM-24x2SRP-4H

CTM-8x1SRB-4H

CTM-10x1SRB-4H

CTM-10x1.25SRB-4H

CTM-12x1.25SRB-4H

CTM-12x1.5SRB-4H

CTM-14x1.5SRB-4H

CTM-16x1.5SRB-4H

CTM-18x1.5SRB-4H

CTM-20x1.5SRB-4H

CTM-22x1.5SRB-4H

CTM-18x2SRB-4H

CTM-20x2SRB-4H

CTM-22x2SRB-4H

CTM-24x2SRB-4H

CTM-8x1SPP-4H

CTM-10x1SPP-4H

CTM-10x1.25SPP-4H

CTM-12x1.25SPP-4H

CTM-12x1.5SPP-4H

CTM-14x1.5SPP-4H

CTM-16x1.5SPP-4H

CTM-18x1.5SPP-4H

CTM-20x1.5SPP-4H

CTM-22x1.5SPP-4H

CTM-18x2SPP-4H

CTM-20x2SPP-4H

CTM-22x2SPP-4H

CTM-24x2SPP-4H

CTM-8x1SPP-5H

CTM-10x1SPP-5H

CTM-10x1.25SPP-5H

CTM-12x1.25SPP-5H

CTM-12x1.5SPP-5H

CTM-14x1.5SPP-5H

CTM-16x1.5SPP-5H

CTM-18x1.5SPP-5H

CTM-20x1.5SPP-5H

CTM-22x1.5SPP-5H

CTM-18x2SPP-5H

CTM-20x2SPP-5H

CTM-22x2SPP-5H

CTM-24x2SPP-5H

CTM-8x1SRP-5H

CTM-10x1SRP-5H

CTM-10x1.25SRP-5H

CTM-12x1.25SRP-5H

CTM-12x1.5SRP-5H

CTM-14x1.5SRP-5H

CTM-16x1.5SRP-5H

CTM-18x1.5SRP-5H

CTM-20x1.5SRP-5H

CTM-22x1.5SRP-5H

CTM-18x2SRP-5H

CTM-20x2SRP-5H

CTM-22x2SRP-5H

CTM-24x2SRP-5H

CTM-8x1SRB-5H

CTM-10x1SRB-5H

CTM-10x1.25SRB-5H

CTM-12x1.25SRB-5H

CTM-12x1.5SRB-5H

CTM-14x1.5SRB-5H

CTM-16x1.5SRB-5H

CTM-18x1.5SRB-5H

CTM-20x1.5SRB-5H

CTM-22x1.5SRB-5H

CTM-18x2SRB-5H

CTM-20x2SRB-5H

CTM-22x2SRB-5H

CTM-24x2SRB-5H

Easy

starting for

through-holes and

blind holes.

Ideal for

blind holes

that are drilled to

a minimum depth.

Free-

cutting for

use in long

through-holes and

in blind holes with

chip clearance.

The Class of Fit (4H or 5H) specifies the pitch diameter tolerance of the tapped hole, with 4H being the tighter range usually specified in

military/aerospace applications, and when consistent locking torque is desired when using locking inserts. Class 5H taps provide a broader toler-

ance range or looser fit, and are normally specified in commercial/industrial applications. The class of fit of the installed insert is controlled by the

class of fit of the tap.

Spiral Pointed

Taps – Plug

(4-Thread

Chamfer)

Coilthread STI Taps - Metric Thread Sizes

(For free machining materials)

For general hand and machine operations.

Provide chip disposal in tapping operations.

18

Nominal Thread Size Class 4H Gage Class 5H Gage

Part Number Part Number

M2.2X0.45 CGM-2.2X.45-4H CGM-2.2X.45-5H

M2.5X0.45 CGM-2.5X.45-4H CGM-2.5X.45-5H

M3X0.5 CGM-3X.5-4H CGM-3X.5-5H