www.asahi-america.com

Engineering

Design Guide

Single Wall Piping x Double Wall Piping xGas & Air Handling Systems

xMaterials xSystem Design x Installation

www.asahi-america.com

ENGINEERING

DESIGN

GUIDE

ASAHI/AMERICA, INC.

Lawrence, Massachusetts

Disclaimer

Asahi/America, Inc. provides this guide to assist engineers in the design of

systems, installers in the installation and owners in the operation. This guide

is designed to provide the best possible recommendations known at the

WLPHRISULQWLQJ(DFKDQGHYHU\W\SHRISLSLQJV\VWHPLVGLႇHUHQWDQGQRRQH

recommendation can cover all conditions. This guide is made available to

assist in the design and installation, but in no way should be construed as a

written recommendation on any system. Each system should be individually

designed and installed based on the responsibility and decisions of the

purchaser. This guide is not a substitute for contacting Asahi/America for

VSHFL¿F UHFRPPHQGDWLRQV RQ D V\VWHP ,Q DGGLWLRQ $VDKL$PHULFD LV QRW

responsible for items not appearing in the guide or recommendations that

may have changed after the printing of this guide. It is recommended in each

FDVHWRFRQVXOW$VDKL$PHULFDIRUVSHFL¿FUHFRPPHQGDWLRQVRQHDFKV\VWHP

Copyright © 2013 Asahi/America, Inc. All rights reserved. Printed in USA.

ABOUT THE COMPANY

Asahi/America, Inc. a wholly-owned subsidiary of Asahi Organic Chemical,

pioneered the market for thermoplastic valves and piping in the United States

and Latin America, during a time when there was no viable alternative to

metal for piping systems. Asahi/America began by promoting valves from a

company known as Asahi Organic Chemical Industry Co., Ltd. (AOC) and piping

through AGRU GmbH in Austria. Through distributor and end user education

and acceptance, the use of thermoplastics has grown. Asahi/America now

manufactures and distributes thermoplastic products including valves, actuators,

single and double wall piping systems and specialty components throughout the

US and Latin America.

$VDKL$PHULFDLVDGLYHUVL¿HG,62FHUWL¿HGPDQXIDFWXUHUDQG

VXSSOLHURIFRUURVLRQUHVLVWDQWÀXLGÀRZSURGXFWV+HDGTXDUWHUHGLQ/DZUHQFH

0DVVDFKXVHWWVZKHUHZHRSHUDWHDVTXDUHIRRWPDQXIDFWXULQJDQG

warehouse facility, Asahi/America supports all of our products with a

comprehensive selection of in-depth technical documents and product

catalogs. To access any of Asahi/America’s technical documentation, testing

information, or product catalogs, visit the company’s website at

www.asahi-america.com or contact customer service at 1-800-343-3618.

What makes Asahi/America special is our ability to provide solutions for

FRUURVLYHRUKLJKSXULW\ÀXLGKDQGOLQJV\VWHPVLQGLYLGXDOL]HGWRPHHWYLUWXDOO\

DQ\FXVWRPHU¶VQHHG7KH$VDKL$PHULFDWHFKQLFDOVWDႇLVDEOHWRSURYLGH

superior knowledge of products, applications and installations. Asahi/America is

poised to support your next project with the assistance of our large distribution

network.

Asahi/America is proud to present this Engineering Design Guide to you. This

publication represents over 40 years of experience, talent, and engineering

H[SHUWLVH,WLVLQWHQGHGWRDLGLQWKHSURFHVVRIHQJLQHHULQJVSHFL¿FDWLRQDQG

design of industrial plastic piping systems using the family of Asahi plastic piping

V\VWHPV:HHQFRXUDJH\RXWRXVHLWRIWHQDQGFDOOXSRQRXUVWDႇRISLSLQJDQG

valve engineers if there is something we have neglected to cover. This is your

JXLGHWRTXDOLW\SODVWLFV\VWHPGHVLJQ

Introduction

Materials

Plastics in Fluid Handling

Thermoplastics at a Glance

General Properties

6SHFL¿F3URSHUWLHV

A

B

C

D

E

F

G

Basic Calculations

SDR - Standard Dimension Ratio

Operating Pressure

Dangerous Media Operating Pressure

Permissible Wall Thickness

External Pressure Calculations

System Calculations

Pressure Curve Graphs

Creep Curves

Vacuum Pressure Charts

Abrasion Resistance

General Chemical Resistance

Leach Out Behavior

Surface Roughness

Production and Packaging

Storage and Transportation

General Installation

Practices

Bending

Socket

Butt/IR

Electrofusion

Hot Air

Mechanical Connections

Special System

Considerations

High Purity

Industrial

Double Contained

Ventilation

Compressed Air

Purad

®

, PolyPure

®

, PP-Pure

®

Proline

®

, Chem Proline

®

, Ultra Proline

®

Duo-Pro

®

, Chem Prolok™, Fluid-Lok

®

PuradVent

®

, ProVent

®

Air-Pro

®

Design &

Pressure Testing

Single Contained

Double Contained

Introduction

Materials

A

B

C

D

E

F

G

Basic Calculations

System Calculations

General Installation Practices

Special System Considerations

Design & Pressure Testing

A

Appendix A - System Tables

B

Appendix B - General Engineering Tables

C

Appendix C - Conversion Tables

655 Andover Street, Lawrence, MA 02148 • Tel: 800-343-3618, 781-321-5409

Fax: 800-787-6861 • https://www.asahi-america.com • Email: [email protected]

Section A

INTRODUCTION

Contents

Plastics in Fluid Handling .........A-2

Thermoplastics at a Glance .......A-3

ASAHI/AMERICA

Rev. 2013-A

A-1

655 Andover Street, Lawrence, MA 02148 • Tel: 800-343-3618, 781-321-5409

Fax: 800-787-6861 • https://www.asahi-america.com • Email: [email protected]

PLASTICS IN FLUID HANDLING

3ODVWLFSLSLQJV\VWHPVDUHRႇHUHGLQDZLGHDVVRUWPHQW

RIPDWHULDOVDQGVL]HV(DFKPDWHULDOKDVXQLTXHDQG

VSHFL¿FPHFKDQLFDOSURSHUWLHV7KHVHGLYHUVHSURSHUWLHV

allow plastic to become the preferred system for many

applications that range from the transport of aggressive

chemicals to the distribution of ultra pure water.

%HFDXVHHDFKPDWHULDOKDVLWVRZQXQLTXHSURSHUWLHV

understanding them becomes vital to the successful

design, installation, and operation of a system.

Asahi/America is proud to present this design guide to

assist design engineers and system installers with the

proper engineering, layout, and installation of plastic

systems. Asahi/America is a pioneer in the manufacture

and distribution of plastic systems in the United States.

6LQFHWKH¶VZHKDYHGHGLFDWHGRXUVHOYHVWR

assisting our customers in achieving the maximum

EHQH¿WVSODVWLFV\VWHPVRႇHU'HVLJQLQJDV\VWHPPDGH

RIWKHUPRSODVWLFPDWHULDOVGLႇHUVFRQVLGHUDEO\IURPWKDW

of metallic materials. No one understands this as well as

$VDKL$PHULFD¶VVDOHVDQGWHFKQLFDOVWDႇ2XUWUDLQHG

VWDႇLVDYDLODEOHWRDVVLVWZLWKDOODVSHFWVRISODVWLF

piping systems. The information contained herein is

GHVLJQHGWRPLQLPL]HWKHHႇRUWVRIHQJLQHHUVGHVLJQHUV

FRQWUDFWRUVDQGUHVHDUFKSURIHVVLRQDOVLQVL]LQJDQG

VHOHFWLQJDOODVSHFWVRIÀXLGV\VWHPV

7KH3ODVWLF%HQH¿W

)RUSLSH¿WWLQJVDQGYDOYHVWKHUPRSODVWLFPDWHULDOV

RႇHUVXSHULRUFRUURVLRQUHVLVWDQFHOLJKWHUZHLJKWVLPSOH

LQVWDOODWLRQDQGDPRUHFRVWHႇHFWLYHDOWHUQDWLYH

Corrosion Resistance

Plastics are non-conductive and are therefore immune

to galvanic or electrolytic erosion. Because plastics are

corrosion resistant, pipe can be buried in acidic, alkaline,

ZHWRUGU\VRLOVZLWKRXWUHTXLULQJDSURWHFWLYHFRDWLQJ,Q

DGGLWLRQFDWKRGLFSURWHFWLRQGHYLFHVDUHQRWUHTXLUHG

Chemical Compatibility

Impervious to many chemicals, thermoplastics are

gaining an ever-increasing acceptance and preference

in a large variety of applications. Additionally, the variety

of materials available allow a wide range of chemical

solutions to be handled successfully with plastic piping.

Thermal Conductance

All plastic piping materials have low thermal

conductance properties. This feature maintains more

XQLIRUPWHPSHUDWXUHVZKHQWUDQVSRUWLQJÀXLGVLQSODVWLF

A

INTRODUCTION

PLASTICS IN FLUID HANDLING

than in metal piping. Low thermal conductivity of the

plastic piping wall may eliminate or greatly reduce the

need for pipe insulation to control sweating.

Low Friction Loss

Because the interior surface of plastic piping is generally

YHU\VPRRWKOHVVSRZHUPD\EHUHTXLUHGWRWUDQVPLW

ÀXLGVFRPSDUHGWRRWKHUSLSLQJV\VWHPV)XUWKHUPRUH

the excellent corrosion resistance of plastics means that

the low friction loss characteristic will not change over

time.

Long-term Performance

Due to the relative chemical inertness and the minimal

HႇHFWVRILQWHUQDODQGH[WHUQDOFRUURVLRQWKHUHLVYHU\

little change in plastic piping’s physical characteristics

over the decades. Examinations of pipe samples

taken from some systems have shown no measurable

GHJUDGDWLRQDIWHU\HDUVRIXVH,QPRVWFDVHV

$VDKL$PHULFDSLSHV\VWHPVDUHGHVLJQHGIRU\HDUV

of service.

Light Weight

Many plastic piping systems are about one-sixth the

weight of steel piping. This lends to lower costs in many

ZD\VORZHUIUHLJKWFKDUJHVOHVVPDQSRZHUVLPSOHU

KRLVWLQJDQGULJJLQJHTXLSPHQWHWF7KLVFKDUDFWHULVWLF

KDVDOORZHGXQLTXHFRVWHႇHFWLYHLQVWDOODWLRQ

procedures in several applications.

Variety of Joining Methods

Plastic piping can be joined by numerous methods.

(DFKPDWHULDOKDVVHYHUDOGLႇHUHQWMRLQLQJPHWKRGV7KH

IROORZLQJOLVWLQFRUSRUDWHVVRPHRIWKHPRVWFRPPRQ

• Solvent cementing

• Socket fusion

• Butt fusion

• Non-contact IR fusion

• Threaded joints

• Flanges

• O-rings

• Rolled grooves

• Mechanical compression joints

The various joining methods allow plastic piping to be

HDVLO\DGDSWHGWRPRVW¿HOGFRQGLWLRQV

A-2

ASAHI/AMERICA

Rev. 2013-A

655 Andover Street, Lawrence, MA 02148 • Tel: 800-343-3618, 781-321-5409

Fax: 800-787-6861 • https://www.asahi-america.com • Email: [email protected]

Nontoxic

Plastic piping systems have been approved for potable

ZDWHUDSSOLFDWLRQVDQGFHUWDLQV\VWHPVDUHUHFRJQL]HG

by the FDA as appropriate material to be in contact

ZLWKIRRGVWXႇ$VHYLGHQFHDOOSODVWLFSRWDEOHZDWHU

piping materials and products are tested and listed for

compliance to ANSI/NSF Standard 61. All ASTM and

AWWA standards for plastic pressure piping that could

be used for potable water contain a provision whereby

WKHUHJXODWRU\DXWKRULW\RUXVHUFDQUHTXLUHSURGXFW

that has been tested and found to be in conformance

with ANSI/NSF Standard 61–Drinking Water System

&RPSRQHQWV±+HDOWK(ႇHFWV:KHQSODVWLFSLSHRU

¿WWLQJVDUH$16,16)6WDQGDUGOLVWHGDQGKDYHWKH

NSF-pw (potable water) mark, they also meet the ANSI/

16)6WDQGDUGUHTXLUHPHQWV7KH16)SZPDUN

FHUWL¿HVWRLQVWDOOHUVXVHUVDQGUHJXODWRUVWKDWWKH

SURGXFWPHHWVWKHUHTXLUHPHQWVRI$16,16)6WDQGDUG

14 for performance and the ANSI/NSF Standard 61 for

KHDOWKHႇHFWV

Biological Resistance

To date, there are no documented reports of any fungi,

bacteria, or termite attacks on any plastic piping system.

In fact, because of its inertness, plastic piping is the

SUHIHUUHGPDWHULDOLQGHLRQL]HGDQGRWKHUKLJKSXULW\

water applications.

Abrasion Resistance

Plastic piping materials provide excellent service in

KDQGOLQJVOXUULHVVXFKDVÀ\DVKERWWRPDVKDQGRWKHU

abrasive solutions. The material toughness and the

smooth inner-bore of plastic piping make it ideal for

applications where abrasion resistance is needed.

Low Maintenance

A properly designed and installed plastic piping system

UHTXLUHVYHU\OLWWOHPDLQWHQDQFHEHFDXVHWKHUHLVQR

rust, pitting, or scaling to contend with. The interior

and exterior piping surfaces are not subject to galvanic

corrosion or electrolysis. In buried applications, the

SODVWLFSLSLQJLVQRWJHQHUDOO\DႇHFWHGE\FKHPLFDOO\

aggressive soil.

THERMOPLASTICS AT A GLANCE

PVC (Polyvinyl Chloride). Asahi/America uses an

XQSODVWLFL]HG39&SRO\PHULQDOORILWV39&YDOYHV39&

has excellent chemical resistance, strength, and rigidity.

It resists attack from most acids and strong alkalies,

as well as gasoline, kerosene, aliphatic alcohols and

A

INTRODUCTION

THERMOPLASTICS AT A GLANCE

hydrocarbons, and salt solutions. Aromatic, chlorinated

RUJDQLFFRPSRXQGVDQGODFTXHUVROYHQWVGRDႇHFW39&

chemical properties. Its low cost and overall property

balance make PVC material best suited to the widest

number of corrosive applications. Its temperature limit is

140°F (60°C).

CPVC (Chlorinated Polyvinyl Chloride). The properties

and advantages of CPVC are very similar to those of

PVC; however, its working temperature range is higher

)&WKDQWKDWRI39&,WVKRXOGEHVSHFL¿HG

WKDWLQLQVWDQFHVZKHUHKRWFRUURVLYHOLTXLGVDUHEHLQJ

KDQGOHGDQH[WUDPDUJLQRIVDIHW\LVUHTXLUHG

PE (Polyethylene). PE is produced from the

SRO\PHUL]DWLRQRIHWK\OHQH+LJKGHQVLW\3(+'3(

RQWKHRWKHUKDQGXVXDOO\KDVDVSHFL¿FJUDYLW\RI

WRJFF3RO\HWK\OHQHFDQEHXVHGLQORZ

temperatures (32°F or colder) without risk of brittle

failure. Thus, a major application for certain PE piping

formulations is for low temperature heat transfer

DSSOLFDWLRQVVXFKDVUDGLDQWÀRRUKHDWLQJVQRZPHOWLQJ

ice rinks, geothermal ground source heat pump piping,

and compressed air distribution. These properties also

make PE ideal for many single and double wall water

reclaim systems.

PP3RO\SURS\OHQH$PHPEHURIWKHSRO\ROH¿QIDPLO\

PP is one of the lightest plastics. It has excellent

chemical resistance to many acids, alkalies, and organic

solvents. PP is one of the best materials to use for

systems exposed to varying pH levels; many plastics

do not handle both acids and bases as well. It is not

recommended for use with hydrocarbons and aromatics.

,WVXSSHUWHPSHUDWXUHOLPLWLV)&

PVDF (Polyvinylidene Fluoride). This high molecular

ZHLJKWÀXRURFDUERQKDVVXSHULRUDEUDVLRQUHVLVWDQFH

dielectric properties, and mechanical strength. These

characteristics are maintained over a temperature range

RI)&WR)&ZLWKDOLPLWHGXVDJH

UDQJHH[WHQGHGWR)&,QSLSLQJV\VWHPV

PVDF is best suited for systems that operate from 0°F

&WR)&39')LVKLJKO\UHVLVWDQW

to wet or dry chlorine, bromine and other halogens,

most strong acids, aliphatics, aromatics, alcohols,

and chlorinated solvents. Because of its extremely

low amounts of extractables, PVDF is widely used to

transport ultra pure water in the semiconductor and

pharmaceutical industries.

A-3

ASAHI/AMERICA

Rev. 2013-A

655 Andover Street, Lawrence, MA 02148 • Tel: 800-343-3618, 781-321-5409

Fax: 800-787-6861 • https://www.asahi-america.com • Email: [email protected]

E-CTFE (WK\OHQH7HWUDÀXRURHWK\OHQH(&7)(

ÀXRURSRO\PHULVFRPPRQO\NQRZQE\LWVWUDGH

name Halar

®

1

(&7)(LVHVVHQWLDOO\D

alternating copolymer of ethylene and CTFE

FKORURWULÀXRURHWK\OHQH,WFRQWDLQVDERXWSHUFHQW

CTFE, one of the most chemically resistant building

blocks that can be used to make a polymer. However,

&7)(KRPRSRO\PHUVDUHGLႈFXOWWRIDEULFDWHH[WUXGH

RUPROG%\WKHFRSRO\PHUL]DWLRQZLWKHWK\OHQH(&7)(

displays much of the chemical resistance of CTFE when

processed. It provides excellent chemical resistance

handling applications that almost all other materials

GRQRW,QSDUWLFXODU(&7)(GHPRQVWUDWHVHႇHFWLYH

handling of fuming acids and chlorinated bases. It is

likely the best material for handling high concentrations

of sodium hypochlorite. Additionally, E-CTFE has good

electrical properties and a broad-use temperature

UDQJHIURPFU\RJHQLFWR)&(&7)(LVD

strong material with excellent impact strength over its

broad-use temperature range. E-CTFE also maintains

useful properties when exposed to cobalt 60 radiation

at dosages of 200 megarands. It is one of the best

ÀXRURSRO\PHUVIRUDEUDVLRQUHVLVWDQFH

PFA3HUÀXRURDONR[\3)$LVLPSHUYLRXVWRDOPRVW

all known chemicals. PFA is a melt processible

ÀXRURSRO\PHUZKLFKDOORZVFRQYHQWLRQDOLQMHFWLRQ

molding and extrusion production methods to be

XWLOL]HG3)$KDVH[FHOOHQWFKHPLFDOUHVLVWDQFHDWKLJK

WHPSHUDWXUHVHYHQXSWR)&$VDKL$PHULFD

uses high purity resins which lend to preferred use in

ultra critical applications.

Further Considerations When evaluating the suitability

of plastics for your application, you should know and

XQGHUVWDQGZKLFKUHVLQLVEHLQJXVHGDQGLWVHႇHFWV

7KHHႇHFWVRIVWDELOL]HUVDQGFRSRO\PHUL]DWLRQGLႇHU

E\PDWHULDO)XUWKHUPRUHDGHVLUHGPDWHULDOHႇHFWIRU

one application may be undesirable for another. PVC

is a prime example of this. In order to be produced,

SXUH39&UHTXLUHVWKHDGGLWLRQRIVWDELOL]HUV7KHVH

VWDELOL]HUVDOORZ39&WREHPROGHGH[WUXGHGDQG

strengthened. For simple plumbing, some chemical

distribution, and other applications, this is acceptable

DQGGHVLUHG+RZHYHUWKHVHVDPHVWDELOL]HUVPDNH

39&XQXVDEOHIRUKLJKHUTXDOLW\XOWUDSXUHZDWHU

applications because they contribute to the water’s

contamination through leaching extractables.

A

INTRODUCTION

THERMOPLASTICS AT A GLANCE

All plastic piping systems begin with the production of

resin. Some resin, such as Solef

®

PVDF, is pure having

been produced without any additives. Others, such as

39&PXVWKDYHVWDELOL]HUVDGGHGWRPDNHWKHPVXLWDEOH

IRUSLSHDQG¿WWLQJSURGXFWLRQ

High Purity PVDF Resin

Not all PVDF resin is the same. As a polymer, resin can

GLႇHUE\WKHOHQJWKRIWKHSRO\PHUDQGLWVPROHFXODU

weight. While maintaining similar chemical compatibility,

UHVLQVRIGLႇHUHQWPROHFXODUZHLJKWKDYHGLႇHUHQW

mechanical properties, welding characteristics, and

PHOWÀRZLQGH[HV0),0DQXIDFWXUHUVLQWHQWLRQDOO\XVH

UHVLQZLWKVOLJKWO\GLႇHUHQWSRO\PHUVWUXFWXUHVIRUWKHLU

SLSH¿WWLQJVDQGYDOYHV7KHUHDVRQIRUWKLVLVVLPSOH

when extruding pipe, it is desirable to use a polymer

with a lower MFI, which easily maintains its form as it

H[LWVWKHH[WUXGHU&RQYHUVHO\¿WWLQJUHVLQLVUHTXLUHG

WRIUHHO\ÀRZWKURXJKWKHPROGDQGHYHQO\¿OOWKHHQWLUH

internal cavity. Therefore, a high MFI is desired. If a

PDQXIDFWXUHUXVHVUHVLQVZLWKODUJHGLႇHUHQFHVEHWZHHQ

WKH0),LQLWV¿WWLQJVDQGSLSHWKHRYHUDOOLQWHJULW\RI

WKHV\VWHPEHFRPHVUHGXFHG3LSHDQG¿WWLQJVGRQRW

weld together properly, and the mechanical properties

PD\EHH[WUHPHO\GLႇHUHQW7KHUHIRUHWKHVFLHQFHRI

polymer pipe system manufacturing is to develop the

skill and expertise to manufacture with resins of the

FORVHVW0),ZLWKRXWVDFUL¿FLQJSURGXFWTXDOLW\3XUDG

®

achieves this through the use of high purity 1000

Series Solef

®

resins by Solvay. Purad

®

exclusively

RႇHUVLWVV\VWHPRIUHVLQZLWKWKHFORVHVW0),DQGLV

produced by the same manufacturer. Furthermore,

manufacturing and packaging of high purity PVDF resin

LVDQLPSRUWDQWIDFWRULQWKHRYHUDOOTXDOLW\RI39')

components. The purity of its components essentially

begins with the resin. Solvay understands this important

fact and carefully manufactures and packages Solef

®

1000 Series resin with the strictest attention to high

purity concerns. Asahi/America and AGRU’s Purad

®

Systems are designed for a variety of applications from

ultrapure water to aggressive chemical distribution.

Purad

®

39')RႇHUVDEURDGUDQJHRIFKHPLFDO

resistance and temperature operation.

A-4

1. Halar is a registered trademark of Ausimont Corporation.

2. Halar® E-CTFE Fluororpolymer Chemical Resistance Data; Ausimont USA, Inc.,

Technical Data Brochure.

ASAHI/AMERICA

Rev. 2013-A

655 Andover Street, Lawrence, MA 02148 • Tel: 800-343-3618, 781-321-5409

Fax: 800-787-6861 • https://www.asahi-america.com • Email: [email protected]

General Properties ............................ B-2

6SHFL¿F3URSHUWLHV .......................... B-11

Section B

MATERIALS

Contents

B-1

ASAHI/AMERICA

Rev. 2013-A

655 Andover Street, Lawrence, MA 02148 • Tel: 800-343-3618, 781-321-5409

Fax: 800-787-6861 • https://www.asahi-america.com • Email: [email protected]

GENERAL PROPERTIES

Overview of Materials

Polypropylene (PP), polyethylene (PE), PVDF, and

Halar

®

are superior materials in terms of resistance

to environmental corrosive agents. All materials are

resistant to a wide variety of organic and inorganic

chemicals of high concentrations and temperatures.

33DQG3(DUHPHPEHUVRIWKHSRO\ROH¿QSODVWLFV

family, have excellent chemical inertness, resistance

WRPRLVWXUHÀRZDQGFRPSOHWHUHVLVWDQFHWRDWWDFNE\

DPELHQWPRLVWXUH7KH\DUHQRWDႇHFWHGE\GHWHUJHQWV

and most inorganic chemicals or organic solvents

below 180°F (82°C) and 140°F (60°C), respectively.

+RZHYHUERWK33DQG3(DUHDႇHFWHGE\KDORJHQV

fuming nitric and sulfuric acids, and other highly

oxidizing environments. Aromatic and chlorinated

hydrocarbons tend to cause swelling and softening at

elevated temperatures, as well. Polypropylene has a

KLJKWHPSHUDWXUHUHVLVWDQFHPDNLQJLWPRUHVXLWDEOH

for a wider range of chemical process applications. PP

is generally suitable up to a maximum temperature of

180°F (82°C). High density polyethylene is rated to a

maximum operating temperature of 140°F (60°C). HDPE

FODVVDQGUHVLQGHSHQGHQWLVDGXFWLOHPDWHULDOPDNLQJ

it preferable for lower temperature application.

PVDF and Halar

®

are members of the inert

ÀXRURSRO\PHUIDPLO\39')LVPDGHIURPSRO\YLQ\OLGHQH

ÀXRULGHDQGKDVHYHQJUHDWHUFKHPLFDOLQHUWQHVVDQG

B

MATERIALS

GENERAL PROPERTIES

UHVLVWDQFHWRPRLVWXUHÀRZWKDQ33DQG3(39')

resists many corrosives, including inorganic substances

such as mineral acids with very low pHs up to operating

temperatures of 280°F (138°C). It shows excellent

resistance to halogens, strong oxidants, and ultra

SXUHZDWHUVROXWLRQV,WLVDႇHFWHGE\VWURQJEDVHRXV

solutions, members of the amine family, and is not

UHFRPPHQGHGIRUKLJKO\SRODUVROYHQWVVXFKDVNHWRQHV

or esters. Halar

®

(E-CTFE) is resistant to the widest

selection of chemical media. It is perfectly suitable for

strong acids and bases, halogens, and ultra pure water.

,WGRHVKDYHDUHGXFWLRQLQUHVLVWDQFHWRFHUWDLQNHWRQHV

Halar

®

has the highest temperature rating of 300°F

(138°C) for continuous operation.

Asahi/America has a very detailed corrosion resistance

GDWDEDVHDYDLODEOHIRUWKHVHVSHFL¿FSURGXFWVZKLFK

includes over 600 corrosive solutions at a variety of

concentrations and operating temperatures. At all

WLPHVUHIHUWRWKHVSHFL¿FFKHPLFDOUHVLVWDQFHJXLGH

for each product. Asahi/America. databases all of its

FKHPLFDOSURMHFWV&KHPLFDOYHUL¿FDWLRQVFRQGXFWHG

E\UHVLQPDQXIDFWXUHUVDUHDOVRNHSWRQ¿OHIRU

reference. When using aggressive chemicals or multiple

chemical mixtures, consult Asahi/America for a written

UHFRPPHQGDWLRQRQWKHVSHFL¿FDSSOLFDWLRQ7RUHFHLYH

a documented recommendation, submit the chemical

concentration, temperature, and operating pressure to

the Asahi/America Engineering Department. A formal

UHVSRQVHLVW\SLFDOO\JHQHUDWHGLQRQHZHHNRUOHVV

B-2

Figure B-1. General comparison of chemical performance of various plastic piping materials

ASAHI/AMERICA

Rev. 2013-A

655 Andover Street, Lawrence, MA 02148 • Tel: 800-343-3618, 781-321-5409

Fax: 800-787-6861 • https://www.asahi-america.com • Email: [email protected]

General Nature of Corrosion and Plastics

Chemical resistance varies greatly between any two

particular families of plastics. Within a given family,

WKHUHDUHDOVRGLႇHUHQFHVEHWZHHQDQ\WZRSDUWLFXODU

plastics. To compound the matter further, chemical

UHVLVWDQFHZLOOYDU\VOLJKWO\EHWZHHQGLႇHUHQWJUDGHVRI

DSDUWLFXODUSODVWLFRUEHWZHHQUHVLQVPDGHE\GLႇHUHQW

PDQXIDFWXUHUV$VSHFL¿FSODVWLFZLOOYDU\VOLJKWO\ZLWK

respect to molecular weight, distribution, degree of

crystallinity, amount of internal plasticization that may

be present (copolymerization), and other properties.

Therefore, it is not suggested that general chemical

resistance tables be used for determining the chemical

resistance of a given manufacturer’s resin. In addition,

it is strongly recommended to avoid extrapolating a

plastic under the notion that it is chemically similar to

DQRWKHULQLWVIDPLO\,WLVUHFRPPHQGHGWKDWDVSHFL¿F

manufacturer’s chemical resistance table be consulted

for the particular product, such as the Asahi/America

tables for Asahi/America products.

7KHPDQQHULQZKLFKDW\SHRIFKHPLFDOPLJKWDႇHFWD

SODVWLFDOVRYDULHVEHFDXVHGLႇHULQJFKHPLFDOVSURGXFH

GLႇHULQJUHDFWLRQPHFKDQLVPVZKHQLQWHUDFWLQJZLWKD

plastic material. Depending on the reaction mechanism,

DQHႇHFWHGSODVWLFPD\EHFRPHEULWWOHVRIWHQHG

charred, crazed, delaminated, discolored, dissolved,

blistered, or swelled. The reaction mechanisms

WKDWSURGXFHWKHVHW\SHVRIHႇHFWVFDQEHJURXSHG

into major categories: chemical reaction, solvation,

absorption, plasticization, and environmental stress

FUDFNLQJ&RPELQDWLRQVRIWKHVHUHDFWLRQPHFKDQLVPV

do occur, and when they do, the detection is more

complex. Chemical reaction is a very general heading

DQGFDQEHEURNHQGRZQLQWRPDQ\GLVWLQFWFDWHJRULHV

Some of these include: oxidation (where chemical bonds

DUHDWWDFNHGK\GURO\VLVQRWSRVVLEOHIRU333(39')

and E-CTFE), dehydration (mostly caused by heat),

DON\ODWLRQKDORJHQDWLRQUDGLDWLRQDQGRWKHUV&HUWDLQ

reactions are predictable due to the resin’s chemical

VWUXFWXUH+RZHYHUDWWDFNXVXDOO\RFFXUVLQDFRPSOH[

manner with respect to polymers, which suggests that

testing be performed under actual conditions in order to

PDNHDGHFLVLRQRQSHUIRUPDQFH

Criteria for Material Selection

There are several conditions that bear particular

LPSRUWDQFHRQWKHLQGLYLGXDOFKHPLFDODWWDFN

PHFKDQLVPVDQGWKHUHIRUHKDYHDJUHDWHႇHFWRQWKH

selection process. The conditions of direct importance

B

MATERIALS

GENERAL PROPERTIES

include: temperature, type of corrosive reagent to be

handled, the particular reagent’s concentration, and the

system’s operating pressure.

7KH(ႇHFWRI7HPSHUDWXUH

7HPSHUDWXUHKDVDVLJQL¿FDQWHႇHFWRQDOORIWKHDWWDFN

PHFKDQLVPV7KHDWWDFNZLOODOPRVWDOZD\VEHGLUHFWO\

related to temperature; increased temperature results

LQDQLQFUHDVHGDWWDFNRQWKHSODVWLFPDWHULDO1RW

only does a temperature increase result in a lowering

of the activation energy required for a reaction to

proceed, but it also causes a polymer to expand. This

results in an increase in permeability, penetrability, and

solubility characteristics of the polymer, which aid in a

FRPELQDWLRQRIWKHGLႇHUHQWPHFKDQLVPV

One important point should be noted regarding

temperature. As a plastic increases through its

WHPSHUDWXUHSUR¿OHWKHUHPD\EHDFHUWDLQWUDQVLWLRQ

WHPSHUDWXUHZKHUHWKHEDVLFVWUHVVFUDFNPHFKDQLVP

PD\EHDOWHUHGDSSUHFLDEO\7KHVLJQL¿FDQFHRIWKLVIDFW

LVWKDWWU\LQJWRH[WUDSRODWHIURPNQRZQSHUIRUPDQFHDW

a low temperature to a high temperature may lead to

erroneous results. A particular danger exists if a data

point is presented at ambient temperature only and an

DWWHPSWLVPDGHWRPDNHDSUHGLFWLRQQHDUWKHSRO\PHU¶V

design temperature limit.

7KH(ႇHFWRI&RQFHQWUDWLRQ

There are many families and types of reagents, each

ZLWKGLႇHUHQWSURSHUWLHVFRQFHUQLQJVROXELOLW\UHDFWLRQ

between other chemical groups, etc. Each will present

DVOLJKWO\GLႇHUHQWFRQFHUQEHFDXVHRIGLႇHUHQWDWWDFN

mechanisms that they can trigger, except a given

polymer type. The reagent’s concentration will also pose

DFRQFHUQDQGFDQUHVXOWLQGLႇHULQJUHDFWLRQUDWHVDW

GLႇHULQJFRQFHQWUDWLRQOHYHOV7KLVLVWUXHIRUDYDULHW\RI

complex reasons. Of particular concern is the mineral

DFLGVJURXS7KLVJURXSFDQVKRZVXEVWDQWLDOO\GLႇHUHQW

HႇHFWVDWYDULRXVOHYHOVRQWKHFRQFHQWUDWLRQSUR¿OH

Again, importance must be given to the concentration

HႇHFWEHFDXVHWHPSHUDWXUHFDXVHVJUHDWFRQFHUQ$

level of concentration can be obtained when suddenly

DWUDQVLWLRQLVDFKLHYHGDQGWKHVWUHVVFUDFNLQJ

mechanism can show substantial change. Extrapolating

UHVXOWVFDXVHGE\NQRZQFRQFHQWUDWLRQVLVDYHU\

dangerous practice and is strongly discouraged. The

more data points available, the better the prediction.

However, testing is always recommended if performance

LVQRWNQRZQ

B-3

ASAHI/AMERICA

Rev. 2013-A

655 Andover Street, Lawrence, MA 02148 • Tel: 800-343-3618, 781-321-5409

Fax: 800-787-6861 • https://www.asahi-america.com • Email: [email protected]

0DQXIDFWXULQJ(ႇHFW

The way a product is manufactured can induce

molded-in stresses that produce changes in chemical

UHVLVWDQFHSDUWLFXODUO\HQYLURQPHQWDOVWUHVVFUDFNLQJ

Manufacturing can also produce surface irregularities

that vary by manufacturer. In general, a smoother

surface will show better results. Built-in stress due

to poor extrusion methods will decrease a system’s

overall chemical resistance. Temperature, pressure, and

FKHPLFDODWWDFNDOODGGWRDV\VWHP¶VVWUHVVOHYHO,IWKH

amount of stress exceeds the allowable hoop stress,

HQYLURQPHQWDOVWUHVVFUDFNLQJZLOORFFXU,WLVWKHUHIRUH

necessary to carefully review all the parameters of an

application.

Chemical Attack Mechanisms

Chemical Reaction Mechanism

&KHPLFDODWWDFNE\FKHPLFDOUHDFWLRQFDQSURFHHGDORQJ

the paths of any of the types of reactions described

earlier, depending on the given chemical and plastic.

,IWKHDFWLYHVLWHVDWWDFNHGDUHDORQJDWWKHHQGVRIWKH

polymer chain, a chain reaction may be initiated leading

to a complete “unzipping” of the polymer structure. If

the sites are distributed, then the polymer will become

scissioned or separated at the distribution sites. This will

OHDGWRDFKHPLFDOEUHDNGRZQRIWKHSRO\PHU'HWHFWLQJ

a chemical reaction occurrence through testing depends

on the rates that these reactions can occur. The typical

properties include molecular weight, dimensions, and

overall appearance, as well as short-term properties,

VXFKDVWHQVLOHVWUHQJWKHORQJDWLRQÀH[XUDOSURSHUWLHV

and others.

A rapid reaction can easily be detected through a

change in molecular weight, color, appearance, etc. A

slower reaction is better detected by the changes in the

previously mentioned short-term mechanical properties.

Quantifying these results is challenging to the designer.

When a plastic’s properties change it is no longer

suitable for a given application. Pay close attention to

the tensile creep rupture tests because this data is the

most important aspect in analyzing design strength of a

plastic piping system.

Solvation Mechanism

6ROYDWLRQHႇHFWRQDWKHUPRSODVWLFXVXDOO\PDQLIHVWV

itself by swelling of the plastic, as well as weight and

dimensional changes. Simple tests similar to those

GHVFULEHGIRUFKHPLFDODWWDFNFDQHDVLO\GHWHFWWKHVH

B

MATERIALS

GENERAL PROPERTIES

changes. Asahi/America materials are very stable

because of their high molecular weights and stable

molecular structures, and therefore are not subject to

VROYDWLRQE\PDQ\NQRZQFRPPRQVROYHQWV

Plasticization

Plasticization typically occurs as an imperfect solvent

and is selectively absorbed into the surface of the

product. It incorporates itself into the molecular structure

of the molecule through secondary bonding. This

typically lowers the mechanical properties and the glass-

transition temperature. The plastic might also tend to

get heavier or larger, but this should only be used as an

LQGLFDWLRQRIWKHHႇHFW,WLVPRUHLPSRUWDQWWRPHDVXUH

the mechanical properties and the glass-transition

temperature.

Environmental Stress Cracking Mechanism

When a plastic is subjected to stresses, it may

experience catastrophic failure due to the initiation and

SURSDJDWLRQRIFUDFNVDQGFUD]HV7KLVSURFHVVLVNQRZQ

DVHQYLURQPHQWDOVWUHVVFUDFNLQJDQGLVLQKHUHQWO\

GLႈFXOWWRSUHGLFW,WLVDVVXPHGWKDWWKHVXUIDFHRIWKH

SODVWLFLVZHDNHQHGE\WKHUHDJHQW¶VFKHPLFDODFWLRQ

$VWKLVORFDOL]HGZHDNHQLQJWDNHVSODFHLWFUDFNV

creating greater surface area while also acting as a

VWUHVVFRQFHQWUDWRU7KHHႇHFWLVWKHUHIRUHPXOWLSOLHG

and further failure occurs until the inevitable catastrophic

failure results.

$FUDFNPD\DSSHDUWKURXJKVHOHFWLYHDEVRUSWLRQRI

the reagent into the polymer chain, selective solvation

of polymer by the reagent from localized areas, or

complexing along the polymer chain at localized sites.

1RPDWWHUZKLFKVHOHFWLYHPHFKDQLVPWKHUHVXOWLV

DOZD\VDZHDNHQLQJRIWKHORFDOL]HGDUHDWKDWUHVXOWV

LQDQLQLWLDOIDLOXUHIROORZHGE\FUDFNSURSDJDWLRQ

7KHUHVXOWRIWKHFUDFNSURSDJDWLRQLVGHVFULEHG

above – greater surface area and stress concentration

with subsequent catastrophic failure. To test for

HQYLURQPHQWDOVWUHVVFUDFNLQJERWKH[SRVXUHDQG

stress must occur at the same time in order to reveal

the mechanism. Because this is the most important

mechanism in piping performance, the following three

tests are used to detect this phenomenon:

• Creep rupture test

• Cantilever beam test

• Stress-relaxation test

B-4

ASAHI/AMERICA

Rev. 2013-A

655 Andover Street, Lawrence, MA 02148 • Tel: 800-343-3618, 781-321-5409

Fax: 800-787-6861 • https://www.asahi-america.com • Email: [email protected]

Testing for Environmental Stress Cracking

Creep Rupture Test

7RWHVWIRUHQYLURQPHQWDOVWUHVVFUDFNLQJWKHEDVLFWHVW

IRUWHQVLOHFUHHS$670'LVPRGL¿HGWRSURGXFH

the desired results. To conduct tests under ambient

temperatures, a set up similar to Figure B-2 can be

used. To conduct measurements of creep strain and

rupture at a variety of temperatures, a test set-up similar

to Figure B-3 might be adapted. In this set-up, the

encasing stainless steel outer pipe could be immersed

into a constant temperature bath.

7KHDGYDQWDJHRIWKLVWHVWLVWKDWVWUHVVFUDFNUHVLVWDQFH

is measured as a direct variable in terms of the plastic’s

reduction in design strength (stress). In addition, the

expected service life could be determined by these

results.

Cantilever Beam Test

The cantilever test is simpler than the creep rupture

test. It is valid primarily when short exposure times

are required and when the material does not show

VLJQL¿FDQWFUHHS,WLVDQH[FHOOHQWWHVWIRUODUJHQXPEHUV

of test specimens. A suggested test set-up is shown in

Figure B-4.

B

MATERIALS

GENERAL PROPERTIES

B-5

Figure B-2. Detail of creep rupture test (ambient

temperatures)

Figure B-3. Detail of creep rupture test (elevated

temperatures)

Figure B-4. Detail of cantilever beam test

for environmental stress cracking (room

temperature)

In the test, the reagent is applied to blotted paper,

and the beam is bent by the clip attached to the end.

Initially, trial and error is used to determine a weight

WKDWZLOOFDXVHFUDFNLQJQHDUWKHEDU¶VPLGSRLQW6WUHVV

and strain will vary in a cantilevered beam from zero

at the free end to the maximum at the clamped end.

&UDFNVZLOOWKHUHIRUHDSSHDUIURPWKHIUHHHQGXQWLO

WKHFRPELQDWLRQRIVWUHVVFUDFNLQJUHDJHQWDQGVWUHVV

reach the critical stress and strain point. The following

formulae can be used to determine critical stress and

strain:

S

C

=

6FL

(B-1)

bt

2

Where: S

C

= critical stress (psi)

F = weight (lb)

L = critical distance (measured from

free end (in)

b = width of the bar (in)

t=WKLFNQHVVRIWKHEDULQ

=

S

C

(B-2)

E

Where:

C

= critical strain (in/in)

E=VKRUWWHUPÀH[XUDOPRGXOXVSVL

ASAHI/AMERICA

Rev. 2013-A

655 Andover Street, Lawrence, MA 02148 • Tel: 800-343-3618, 781-321-5409

Fax: 800-787-6861 • https://www.asahi-america.com • Email: [email protected]

Stress-Relaxation Test

A third alternative is to test a specimen under stress by

VXEMHFWLQJLWWRD¿[HGGHÀHFWLRQ7KLVWHVWHOLPLQDWHVWKH

QHHGIRUZHLJKWVDQGWDNHVXSOLWWOHVSDFH$VXJJHVWHG

set-up is shown in Figure B-5.

7KHWHVWLVOLPLWHGWRPRUHÀH[LEOHSODVWLFVDQGVLWXDWLRQV

ZLWKVKRUWHUVWUHVVFUDFNLQJGXHWRVWUHVVUHOD[DWLRQ

7RFDOFXODWHFULWLFDOVWUDLQZKHUHVWUHVVFUDFNLQJ¿UVW

appears, use the following equation:

PE General

General properties of PE (Polyethylene)

As PE molding materials are continually developed, the

HႈFLHQF\RI3(SLSHVDQG¿WWLQJVKDYHEHHQLPSURYHG

considerably. This fact is due to the introduction of new

LQWHUQDWLRQDOVWDQGDUGV,62(1(1

which lead to higher permissible operating pressures.

Polyethylene (PE) for pressure pipe applications is

QRORQJHUFODVVL¿HGE\LWVGHQVLW\IRUH[DPSOH3(/'

PE-MD, PE-HD); it is now divided into MRS strength

classes.

Compared to other thermoplastics, PE shows an

H[FHOOHQWGLႇXVLRQUHVLVWDQFHDQGKDVWKHUHIRUHEHHQ

used to safely transport gases for many years. The new

FODVVL¿FDWLRQLVEDVHGRQWKHPLQLPXPUHTXLUHGVWUHQJWK

B

MATERIALS

GENERAL PROPERTIES

(MRS), which is applied to design long-term loaded PE

pipes that operate at a temperature of + 68° F (20°C)

IRUDWOHDVW\HDUV7KHUHIRUHWKH¿UVWJHQHUDWLRQ

pipes are named PE32, PE40, and PE63; the second-

generation pipes are labeled PE80; the third generation

LVQDPHG3(7KH¿JXUHVVWDQGIRUWKH056YDOXHV

in bar. Expressed in megapascal, the design stresses

for PE80 and PE100 pipes will consequently be 8.0 and

10.0 MPa.

Other essential advantages of this material are the

89VWDELOLW\LILWLVEODFNDQGWKHÀH[LELOLW\RIWKHPROGLQJ

PDWHULDOÀH[LEOHSLSLQJV\VWHP

Chemical structure of PE

Physiologically non-toxic

Polyethylene’s composition complies with relevant food

VWXႇUHJXODWLRQVDFFRUGLQJWR)'$&)5g1250

B 5014, Part 1, BGA, KTW guidelines). PE pipes and

¿WWLQJVDUHYHUL¿HGDQGUHJLVWHUHGIRUSRWDEOHZDWHU

VXLWDELOLW\DFFRUGLQJWR'9*:JXLGHOLQH:DQG16)

61-G.

Radiation strain

Pipes made of polyethylene may be applied across

the range of high-energy radiation. Pipes made from

PE are suitable for radioactive sewage water drainage

from laboratories and as cooling water piping systems

for the nuclear energy industry. Radioactive sewage

waters usually contain beta and gamma rays. PE piping

systems do not become radioactive, even after many

years of use. Also, in a higher radioactivity environment,

PE pipes are not damaged if they are not exposed

during their complete operation time to a larger, regularly

spread radiation dose of < 10

4

Gray.

Polyethylene type PE100

These materials are also described as third generation

(PE-3) polyethylene types and MRS 10 materials. A

PRGL¿HGSRO\PHUL]DWLRQSURFHVVDQGDPHQGHGPRO

mass distribution shows this development. Therefore,

3(W\SHVKDYHDKLJKHUGHQVLW\VWLႇQHVVDQG

hardness. Also, the creep pressure and resistance

DJDLQVWUDSLGFUDFNSURSDJDWLRQDUHLQFUHDVHG

B-6

Figure B-5. Detail of stress-relaxation test

C

=

[

bt

2a

2

(1-x

2

)

(

1

a

2

-

b

a

4

)]

(B-3)

Where:

C

= critical strain (in/in)

a = semi-major axis of ellipse (in)

b = semi-minor axis of ellipse (in)

x = distance along major axis (in)

t=WKLFNQHVVLQ

ASAHI/AMERICA

Rev. 2013-A

655 Andover Street, Lawrence, MA 02148 • Tel: 800-343-3618, 781-321-5409

Fax: 800-787-6861 • https://www.asahi-america.com • Email: [email protected]

Consequently, this material is suitable for the production

of pressure pipes with larger diameters. In comparison

WRXVXDO3(SUHVVXUHSLSHVZLWKOHVVZDOOWKLFNQHVVHVLW

achieves the corresponding pressure rating.

0RGL¿HGSRO\HWK\OHQH3(HO3RO\HWK\OHQH

electro-conductible)

Due to electro-conductibility, PE-el is often used to

transport easily combustible media or to convey dust. An

earthed connection can be performed.

Advantages of PE:

• 89UHVLVWDQFHEODFN3(

• Flexibility

• /RZVSHFL¿FZHLJKWRIDSSUR[LPDWHO\JFP

3

• Favorable transportation (e.g., coils)

• Very good chemical resistance

• Weathering resistance

• Radiation resistance

• Good weldability

• Very good abrasion resistance

• 1RGHSRVLWVDQGQRRYHUJURZWKSRVVLEOHGXHWR

less frictional resistance

• Less pressure

• Losses in comparison with metals, etc.

• Freeze resistance

• Rodent resistance

• Microbic corrosion resistance

PP General

Proline

®

(industrial grey), PP-Pure

®

(high purity PP grey)

and PolyPure

®

(high purity PP natural) piping systems

are made out of specially selected polypropylene

material PPR (polypropylene random-copolymer). These

are thermoplastic materials that distinguish themselves

E\DORZVSHFL¿FZHLJKWDQGH[FHOOHQWSURFHVVLELOLW\

weldability, and formability. These materials contain

additives (e.g., stabilizers) but no plasticizers.

General properties of PP

$FFRUGLQJWR',1WKUHHGLႇHUHQWW\SHVRI

polypropylene are recognized:

• Type 1: PPH

(homopolymere)

• Type 2: PPB

EORFNFRSRO\PHUH

• Type 3: PPR

(random-polymere)

B

MATERIALS

GENERAL PROPERTIES

Copolymerization with ethylene creates special

properties, which results in improved processability

HJORZHUGDQJHURIVKULQNDJHFDYLWDWLRQDWWKH

injection molding process) and higher product impact

strength compared to PPH polypropylene homopolymer.

Therefore, PP-Pure

®

and PolyPure

®

are especially

suitable in the chemical and semiconductor industry for

UPW-systems where chemical resistance is imperative.

AGRU pipes, sheets, and round bars have been

PDGHRIQXFOHDWHG33+%HWDȕ33VLQFHWKHPLG

1970s. Fittings have also been produced out of PPR

(polypropylene random-copolymer) since the end of the

1970s. Both types have been stabilized against high

temperatures and are the best suited materials for the

production of pressure piping systems. In comparison

to other thermoplastics such as PE and PVC, PP shows

a thermal stability up to 212°F (100°C) (short-time up to

250°F (120°C) for pressureless systems).

PP also shows good impact strength in comparison to

PVC. The impact strength depends on temperature; it

increases with rising temperatures and decreases with

falling temperatures.

Chemical structure of Polypropylene

Physiological non-toxicity

Polypropylene’s composition complies with the relevant

IRRGVWXႇUHJXODWLRQVDFFRUGLQJWRg1250%SDUW

1. FDA. BGA. KTW guidelines).

Advantages of Polypropylene:

• /RZVSHFL¿FZHLJKWRIJFPñ

39&JFPñ

• High creep resistance

• Excellent chemical resistance

• High resistance to aging due to thermal

stabilizing

• Good weldability

• Excellent abrasion resistance

• Smooth inside surface

B-7

ASAHI/AMERICA

Rev. 2013-A

655 Andover Street, Lawrence, MA 02148 • Tel: 800-343-3618, 781-321-5409

Fax: 800-787-6861 • https://www.asahi-america.com • Email: [email protected]

• 1RGHSRVLWVDQGQRRYHUJURZWK

• Less frictional resistance

• 1RQFRQGXFWLYH

• Good insulating characteristics

• Energy-rich radiation

Radiation strain

At an absorbed dose of < 10

4

Gray, polypropylene piping

systems can be applied without decreasing essential

resistance. At energy rays above 10

4

Gray, temporary

resistance may increase due to the molecular structure

FURVVOLQNLQJ%XWDWGXUDEOHUDGLDWLRQVWUDLQLWUXSWXUHV

the molecular chains and damages the material to a

serious resistance decrease.

UV radiation

Polypro piping systems are not UV-stable, so they must

be adequately protected. A protection layer or insulation

is possible to protect against direct solar radiation. For

pigmented systems, it is possible to compensate the

VXUIDFHGDPDJHE\LQFUHDVLQJZDOOWKLFNQHVVDVWKH

damage only occurs on the surface (according to the

'967KHZDOOWKLFNQHVVDGGLWLRQFDQQRWEHOHVV

than 2 mm with a 10 year maximum expected operating

period. Because polypropylene is not normally equipped

with light-stable color pigments, it may change colors

(fade) due to weathering.

$VDQDOWHUQDWLYHDKLJKWHPSHUDWXUHUHVLVWDQWEODFN33

PDWHULDOFDQEHXVHG7KHEODFN33PDWHULDOLVVWDELOL]HG

against UV radiation for 10 years. The conditions

IRUDSSOLFDWLRQVKRXOGEHFODUL¿HGZLWKWKHWHFKQLFDO

engineering department.

Discoloration of PolyPure

®

At higher temperatures, a discoloration of the material

DSSHDUVEXWWKLVKDVQRLQÀXHQFHRQWKHSURGXFW¶V

performance with regard to its mechanical, thermal,

purity, or electrical properties.

PPR and copper

Direct contact with copper, especially at higher

temperatures, deteriorates the physical properties of

PPR. Due to the accelerated thermal oxidation, heat

aging is faster.

*HQHUDOSURSHUWLHVRIPRGL¿HG33

Flame retardant (PP-s) and electro-conductive (PP-el)

have been developed because of an increase in new

VSHFL¿FUHTXLUHPHQWVIRUWKHFRQVWUXFWLRQRISLSLQJ

B

MATERIALS

GENERAL PROPERTIES

systems for the chemical industry and apparatus

engineering. For example, static charging caused by

WKHÀRZRIÀXLGVRUGXVWFDQDULVHGXULQJWKHRSHUDWLRQ

of thermoplastic piping systems. Electro-conductible

polypropylene types have been developed in order to

HQDEOHDQHDUWKFRQQHFWLRQ7KHVHPRGL¿HGSURSHUWLHV

are achieved with the supplement of additives, but this

results in alterations to the mechanical, thermal, and

chemical properties in comparison to the standard type.

Therefore, it is necessary to clarify all projects with our

technical engineering department.

Physiological properties

0RGL¿HG33W\SHVÀDPHUHWDUGDQW

and electro-

conductible PP) correspond in composition because

of the supplement of additives and not because of the

UHOHYDQWIRRGVWXႇUHJXODWLRQV7KHUHIRUHWKH\PD\QRW

be used for potable water pipes and in contact with food

VWXႇ

PVDF General

*HQHUDOSURSHUWLHVRI39')3RO\YLQ\OLGHQHÀXRULGH

PVDF is an extremely pure polymer and contains no

UV stabilizers, thermostabilizers, softeners, lubricants,

RUÀDPHUHWDUGDQWDGGLWLYHV,WLVSDUWLFXODUO\VXLWDEOHIRU

ultra pure water constructions and for the transport of

clear chemical liquids in the semiconductor industry.

Due to its chemical inertness, reaction against most

media is nearly impossible. Pipes and components

PDGHRXWRIVXLWDEOHVWDQGDUGW\SHVIXO¿OOWKHKLJK

demands of the semiconductor industry; for example,

WKH\DUHLQWKHSRVLWLRQWRPDLQWDLQWKHVSHFL¿F

UHVLVWDQFHRIGHLRQL]HGXOWUDSXUHZDWHURYHU0ȍFP

39')RႇHUVDQLGHDOFRPSURPLVHZLWKLWVSURSHUWLHV

in connection with very easy processing and an

advantageous price-performance ratio.

PVDF is distinguished by its high mechanical strength

and very good chemical resistance, even for applications

in the presence of critical chemical media in the high

temperature range.

B-8

ASAHI/AMERICA

Rev. 2013-A

655 Andover Street, Lawrence, MA 02148 • Tel: 800-343-3618, 781-321-5409

Fax: 800-787-6861 • https://www.asahi-america.com • Email: [email protected]

Chemical structure of PVDF

PVDF is obtained by the polymerization of vinylidene

ÀXRULGHDQGLWFRUUHVSRQGVWRWKHIROORZLQJFKHPLFDO

structure:

The two main processes to produce PVDF are:

• The emulsion polymerization process

PVDF type I according ASTM D 3222

• The suspension polymerization process

PVDF type II according ASTM D 3222

PVDF material that is produced through the suspension

SRO\PHUL]DWLRQSURFHVVRႇHUVIHZHUVWUXFWXUDOGHIHFWV

resulting in higher crystallinity as well as better

mechanical properties and long-term behavior. Purad

®

uses only suspension PVDF in order to provide the best

possible product quality.

Fire resistance

PVDF UHP is a halogen-containing polymer, which

RႇHUVH[FHOOHQW¿UHSURWHFWLRQZLWKRXWÀDPHUHWDUGDQW

additives. During the combustion of PVDF UHP, only

DVOLJKWDPRXQWRIVPRNHGHYHORSPHQWDULVHV:LWKDQ

oxygen index of about 44 percent, PVDF UHP received

WKHKLJKHVWÀDPPDELOLW\FODVVL¿FDWLRQ9DFFRUGLQJWR

UL-94.

Physiological properties

PVDF-UHP is physiologically harmless, non-toxic, and

conforms to FDA regulations as outlined in Title 21.

Chapter 1. Part 177-2510 (contact with food).

Advantages of PVDF:

• Wide application temperature range

(-4°F to 248°F)

• +LJKKHDWGHÀHFWLRQWHPSHUDWXUH

• Very good chemical resistance, even at high

temperatures

• *RRGUHVLVWDQFHDJDLQVW89DQGڸUDGLDWLRQ

• Pure material without additives

• Very good surface quality

• High aging resistance and good thermal stability

B

MATERIALS

GENERAL PROPERTIES

• Excellent abrasion resistance

• Very good anti-friction properties

• Good mechanical properties

• Excellent insulation characteristics

• Flame retardant

• Physiologically non-toxic

• Good and simple processability

• Energy-rich radiation

7KHHႇHFWVRIJDPPDg) rays on PVDF UHP are

VLJQL¿FDQWO\ORZHUWKDQLQPDQ\RWKHUKDORJHQSRO\PHUV

(e.g., PFA, PTFE, PVC). PVDF is resistant to highly

HQHUJHWLFUDGLDWLRQ7KLVIDFWPDNHV39')VXLWDEOHIRU

XVHLQWKHQXFOHDULQGXVWU\7KHFURVVOLQNLQJRIWKH

SRO\PHUEHJLQVZLWKNLORJUD\

UV radiation

Suspension grade PVDF contains a high percentage of

ÀXRULQH7KHERQGEHWZHHQWKHKLJKO\HOHFWURQHJDWLYH

ÀXRULGHDQGFDUERQDWRPLVH[WUHPHO\VWURQJZLWKD

GLVVRFLDWLRQHQHUJ\RINMPRO7KHUHIRUH39')8+3

is resistant to ambient UV radiation (>232 nm).

Solubility

The PVDF-homopolymere swells in high polar solvents,

such as acetone and ethylacetat, and is soluble

in polar solvents, such as dimethylformamide and

dimethylacetamide.

Fluoropolymers

General properties of E-CTFE

(WK\OHQHFKORURWULÀXRUHWK\OHQH

(&7)(NQRZQDV+DODU

®

) has a unique combination of

properties as a result of its chemical structure, which is a

copolymere with a changing constitution of ethylene and

FKORURWULÀXRUHWK\OHQH

E-CTFE provides excellent chemical resistance and

high mechanical strength, even at high temperatures.

These characteristics enable the use of E-CTFE as

DFRVWHႇHFWLYHVROXWLRQIRUPDQ\DSSOLFDWLRQVZLWK

ultra pure media.

Furthermore, E-CTFE has an inherent resistance to

many aggressive chemicals, even corrosive acids,

DONDOLVDQGVROYHQWVDQGLWLVDOVRUHVLVWDQWLQFRQWDFW

with chlorine. It can withstand pH values from 0 to 14.

7KHUHDUHRQO\DIHZFKHPLFDOVWKDWDႇHFW(&7)(VXFK

as hot amines, sodium, and potassium.

B-9

ASAHI/AMERICA

Rev. 2013-A

655 Andover Street, Lawrence, MA 02148 • Tel: 800-343-3618, 781-321-5409

Fax: 800-787-6861 • https://www.asahi-america.com • Email: [email protected]

Chemical structure of E-CTFE

Physiological properties

E-CTFE is suitable for the safe application of products in

FRQWLQXRXVFRQWDFWZLWKIRRGVWXႇDFFRUGLQJWRWKH)'$

³%*$'HXWVFKODQG´)RUDYRLGLQJHYHU\LQÀXHQFHRI

smell and taste, it is recommended to use water to clean

the food that has direct contact with E-CTFE parts.

Advantages of E-CTFE:

• Wide temperature application range (thermal

resistance from -105°F to 340°F (-105°C to 171°C)

• *RRGUHVLVWDQFHWR89DQGȖUDGLDWLRQWKHUHIRUH

favorable aging resistance

• Flame retardant (UL 94-V0 material) - oxygen index

52 percent

• Extremely good chemical resistance to most

WHFKQLFDODFLGVDONDOLVDQGVROYHQWVDVZHOODVLQ

contact with chlorine

• Excellent insulating properties in connection with

very good electrical values

• Physiologically non-toxic

• Exceptional surface smoothness

• Excellent impact strength

• Excellent tensile strength

• Highest creep modulus

• Extremely low permeability

• Excellent abrasion resistance

• Energy-rich radiation

E-CTFE has an extraordinary inherent resistance to

JDPPDJUD\V7KHUHIRUH(&7)(LVQRWLQÀXHQFHGE\

the radiation of Cobalt-60 up to 2 MGy.

Fire resistance

(&7)(KDVWKHEHVWÀDPPDELOLW\UHVLVWDQFH8/9

DQGDYHU\ORZVPRNHJHQHUDWLRQRI/2,!SHUFHQW

B

MATERIALS

GENERAL PROPERTIES

Surface quality

(&7)(LVGLVWLQJXLVKHGIURPDOORWKHUÀXRURSRO\PHUVE\

its exceptional surface smoothness, which precludes the

shedding of particles and avoids particle trapping. The

surface of E-CTFE exhibits a low incidence of microbial

ELRIRXOLQJPDNLQJLWLGHDOIRUXVHLQ83:DSSOLFDWLRQV

UV radiation

E-CTFE shows only a slight change of the properties

or appearance weathering in the sunlight. Reaped

ZHDWKHULQJWHVWVVKRZHGDUHPDUNDEOHVWDELOLW\RIWKH

SRO\PHUVSDUWLFXODUO\WKHHORQJDWLRQDWEUHDNZKLFKLVD

good indicator for the polymer decomposition. Even after

1,000 hours in a “Weather-Ometer” with xenon light, the

LPSRUWDQWSURSHUWLHVDUHKDUGO\LQÀXHQFHG

Thermal properties

(&7)(KDVDUHPDUNDEOHUHVLVWDQFHDJDLQVW

decomposition through heat, intensive radiation, and

weathering. It is resistant against temperatures up to

303°F (150°C) for an extensive length of time, and it is

one of the best plastics with a good resistance against

radiation.

Radiation resistance

(&7)(VKRZVDQH[FHOOHQWUHVLVWDQFHDJDLQVWGLႇHUHQW

radiations. It even has good values after irradiation with

200 megarad Cobalt-60.

Mechanical properties

E-CTFE is a solid, highly impact-resistant plastic that

hardly changes its properties over a wide range of

temperatures. In addition to the good impact strength,

(&7)(KDVDJRRGEUHDNLQJVWUDLQDQGJRRGDEUDVLRQ

behavior. It is also important to emphasize the good

behavior at low temperatures, especially the high impact

strength.

Reproduction of microorganisms on E-CTFE

The surface of an E-CTFE product is unfavorable to the

proliferation of microorganisms. This conclusion is the

result of an examination that was executed within the

IUDPHZRUNRIDWHVWRIWKH+3VXLWDELOLW\RI(&7)('XH

to these properties, E-CTFE is applied in the food and

drug industry and for ultra pure water ranges.

B-10

ASAHI/AMERICA

Rev. 2013-A

655 Andover Street, Lawrence, MA 02148 • Tel: 800-343-3618, 781-321-5409

Fax: 800-787-6861 • https://www.asahi-america.com • Email: [email protected]

B

MATERIALS

SPECIFIC PROPERTIES

SPECIFIC PROPERTIES

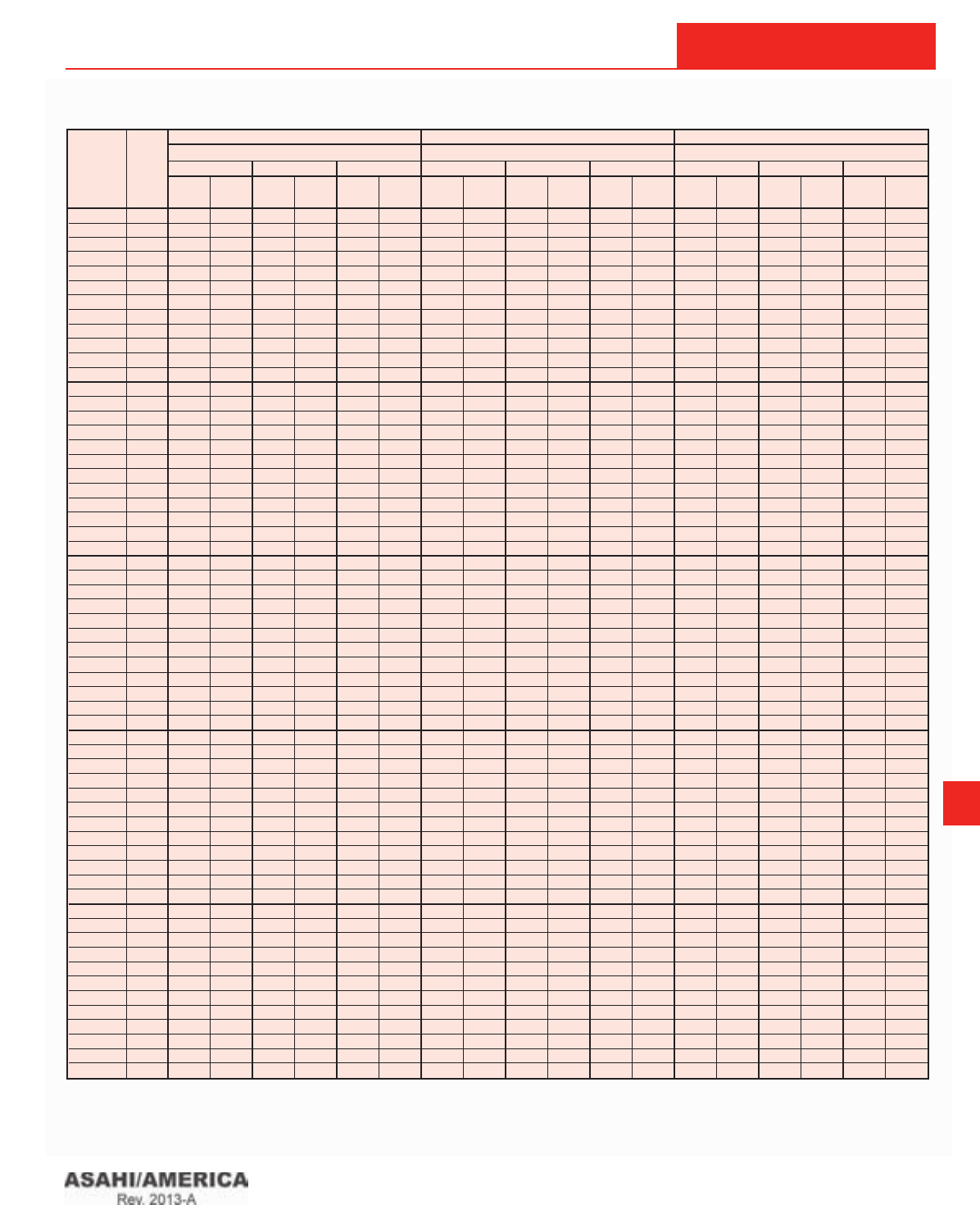

6SHFL¿FPDWHULDOSURSHUWLHV3(3339')(&7)(

B-11

3OHDVHVHHSURGXFWVSHFL¿FDWLRQVRQZZZDVDKLDPHULFDFRP

ASAHI/AMERICA

Rev. 2013-A

655 Andover Street, Lawrence, MA 02148 • Tel: 800-343-3618, 781-321-5409

Fax: 800-787-6861 • https://www.asahi-america.com • Email: [email protected]

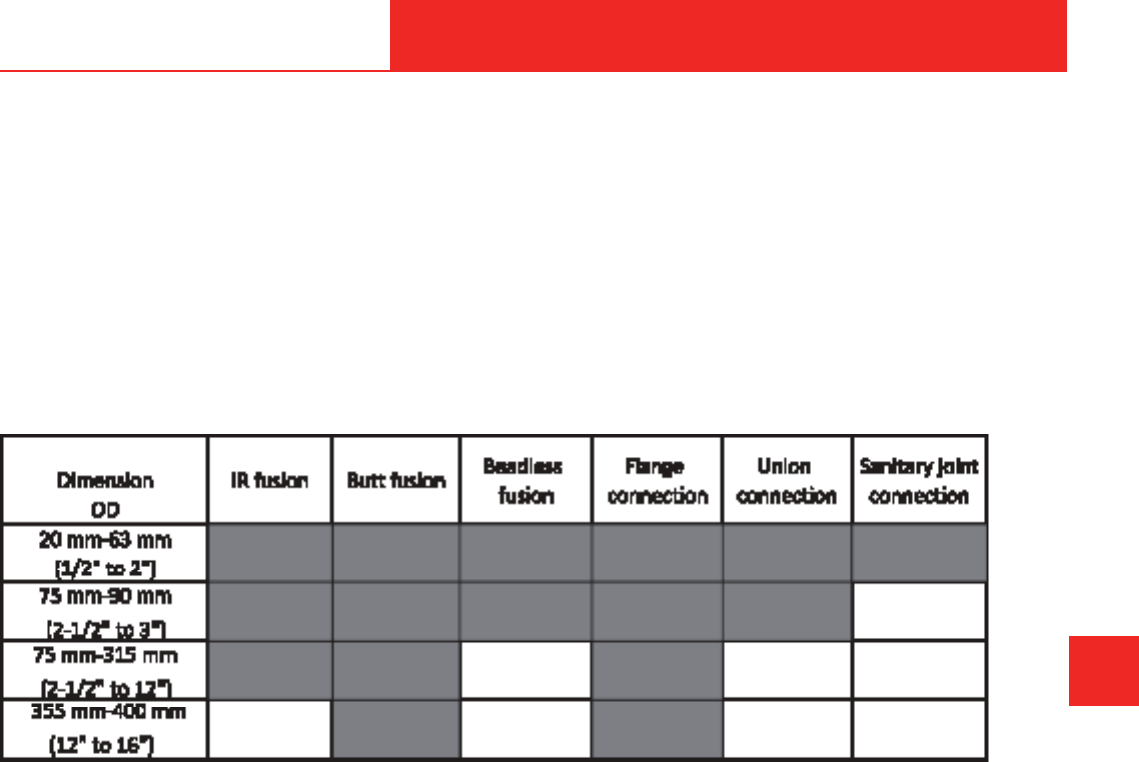

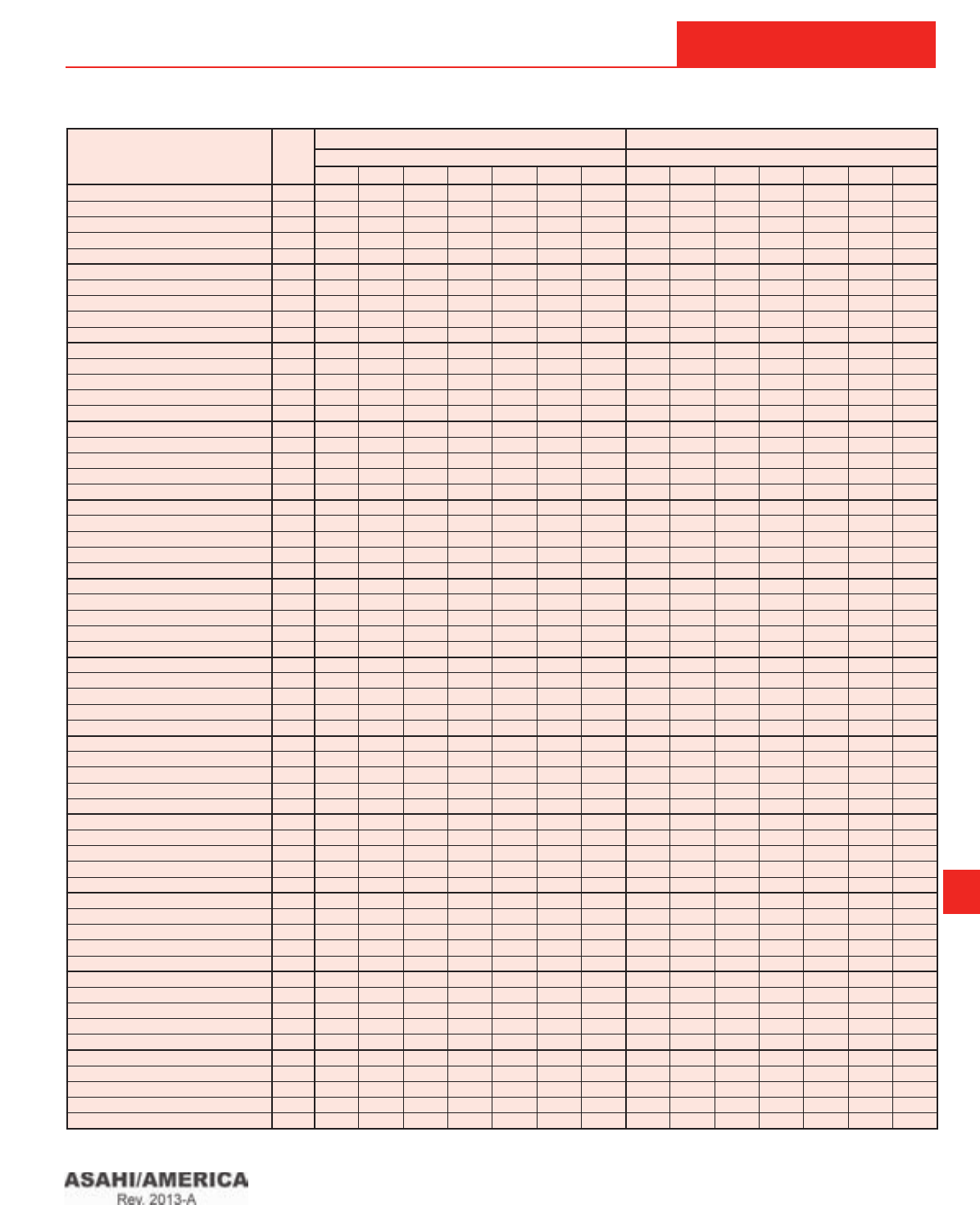

Applications

7KHWDEOHEHORZJLYHVDVXUYH\RIWKHGLႇHUHQWDSSOLFDWLRQSRVVLELOLWLHVRIRXUPROGLQJPDWHULDOV

B

MATERIALS

SPECIFIC PROPERTIES

B-12

Table B-6. Application Recommendations

ASAHI/AMERICA

Rev. 2013-A

655 Andover Street, Lawrence, MA 02148 • Tel: 800-343-3618, 781-321-5409

Fax: 800-787-6861 • https://www.asahi-america.com • Email: [email protected]

SDR - Standard Dimension Ratio .... C-2

Operating Pressure ............... C-2

Dangerous Media Operating Pressure C-3

Permissible Wall Thickness ........ C-4

External Pressure Calculations ..... C-5

Section C

BASIC CALCULATIONS

Contents

C-1

ASAHI/AMERICA

Rev. 2013-A

655 Andover Street, Lawrence, MA 02148 • Tel: 800-343-3618, 781-321-5409

Fax: 800-787-6861 • https://www.asahi-america.com • Email: [email protected]

SDR - STANDARD DIMENSION RATIO

SDR =

da

(C-1)

s

Where: SDR = Diameter - wall thickness relation

da = outside diameter [mm]

s = wall thickness

S - series

OPERATING PRESSURE

PB

=

ı

v

(C-3)

(SDR - 1) • C

min

Where:

PB

= Component operating pressure

[bar]

ı

v

= Reference strengh [N/mm

2

]

(see the pressure curve for each

material in Section D)

SDR = Standard Dimension Ratio

C

min

= Minimum safety factor

(see table c-1)

C

BASIC CALCULATIONS

SDR

C-2

S =

SDR - 1

(C-2)

2

Where: SDR = Diameter - wall thickness relation

Example:

da = 110 mm

s = 10 mm

SDR =

da

=

110

=11

(C-1

Example)

s10

Example:

SDR = 11

S=

SDR - 1

=

11 - 1

=5

(C-2

Example)

22

Example:

3(&\HDUVZDWHUı

v

= 10)

SDR = 11

C

min

= 1.25

PB

=

ı

v

=

20 • 10

=16

(C-3

(SDR - 1) • C

min

(11 - 1) • 1.25 Example)

The following calculations are shown using

metric units for simplicity. Asahi/America

engineering staff is happy to assist with any

questions you may have.

Unit conversion: 1 bar = 14.5psi

25.4 mm = 1 inch

Table C-1. Safety Factor

ASAHI/AMERICA

Rev. 2013-A

655 Andover Street, Lawrence, MA 02148 • Tel: 800-343-3618, 781-321-5409

Fax: 800-787-6861 • https://www.asahi-america.com • Email: [email protected]

DANGEROUS MEDIA OPERATING

PRESSURE

Operating pressure for dangerous media

In order to calculate the respective permissible highest

RSHUDWLQJSUHVVXUHIRUFRQYH\LQJGDQJHURXVÀXLGV

the operating pressure value can be looked up for

the corresponding parameter in the relevant table for

permissible system operating pressures (valid for water).

Then, this operating pressure has to be reduced by the

UHOHYDQWUHGXFLQJFRHႈFLHQWV7KHWRWDOVDIHW\FRHႈFLHQW

LVDWDPLQLPXP+LJKHUVDIHW\FRHႈFLHQWVDUH

DSSOLHGIRULPSDFWVHQVLWLYHPRGL¿HGPDWHULDOVDW+'3(

2.4, PP-s and PP-R-s-el 3.0).

Example:

Pa

=

PB

(C-7)

fAP • fCR • AZ

Where:

Pa

= Operating pressure of the relevant

application [bar]

PB

= Component operating pressure, valid

for water [bar] (Formula C-3)

fAP

= Application factor

is an additional reducing factor which

UHVXOWVLQDWRWDOVDIHW\FRHႈFLHQWRI

2.0 at a minimum by multiplication

with the C-factors according to DIN.

(Table C-2)

fCR

= Chemical resistance factor according

to DVS

AZ

= 5HGXFLQJIDFWRUIRUWKHVSHFL¿F

tenacity (Table C-3)

C

BASIC CALCULATIONS

DANGEROUS MEDIA

C-3

Application factors f

AP

for water-dangerous media:

3(&\HDUVZDWHUGKı

v

= 10)

SDR = 11

C

min

= 1.25

Chemicals: H

2

SO

4

(sulfuric acid), Concentration 53%

f

CR

= 2.0 (acc. DVS 2205, part 1)

PB

=

ı

v

=

20 • 10

=16 (C-8)

(SDR - 1) • C

min

(11 - 1) • 1.25

Pa

=

PB

=

16

=5

fAP • fCR • AZ

1.6 • 2.0 • 1

Reducing factor A

Z

IRUWKHVSHFL¿FWHQDFLW\E\ORZ

temperatures

Table C-2. Application Factors

Table C-3. Reducing Factor

ASAHI/AMERICA

Rev. 2013-A

655 Andover Street, Lawrence, MA 02148 • Tel: 800-343-3618, 781-321-5409

Fax: 800-787-6861 • https://www.asahi-america.com • Email: [email protected]

PERMISSIBLE WALL THICKNESS

Calculation of the permissible wall

thickness s

min

In general, strength calculations of thermoplastic piping

systems are based on long-term values. The strength

values, depending on temperature, are given in the

pressure curves (see Section D). After calculation of the

theoretical wall thickness, the construction wall thickness

has to be determined under consideration of the nominal

pressure and SDR class. Additional wall thickness

sometimes has to be considered (e.g., application of PP

piping systems outdoor without UV protection for the

transport of abrasive media).

s

min

=

p • da

(C-9)

ı

zul

+ p

When: ı

zul

= ı

v

C

min

Where: s

min

= Minimum wall thickness [mm]

p = Operating pressure [bar]

da = Pipe outside diameter [mm]

ı

zul

= Maximum permitted stress

(see pressure curves sec D. [N/mm

2

]

ı

v

= Reference stress [N/mm

2

]

C

min

= Minimum safety factor (See Table C-1)

C

BASIC CALCULATIONS

WALL THICKNESS

Example:

3(&\HDUVZDWHUGKı

v

= 10)

Operating pressure 16bar

Outside diameter da = 110 mm

C-4

,IQHFHVVDU\WKHUHIHUHQFHVWUHVVı

v

) and the operating

pressure (p) can also be calculated from this formula.

ı

zul

=

p • (da - s

min

)

=

16 • (110 - 10)

= 8 (C-12)

20 • s

min

20 • 10

ı

zul

=

p • (da - s

min

)

(C-11)

20 • s

min

And

p=

ı

zul

•

s

min

da - s

min

ı

zul

=

ı

v

=

10

= 8 (C-10)

C

min

1.25

s

min

=

p • da

=

16 • 110

=10

ı

zul

+ p 20 • 8 • 16

ASAHI/AMERICA

Rev. 2013-A

655 Andover Street, Lawrence, MA 02148 • Tel: 800-343-3618, 781-321-5409

Fax: 800-787-6861 • https://www.asahi-america.com • Email: [email protected]

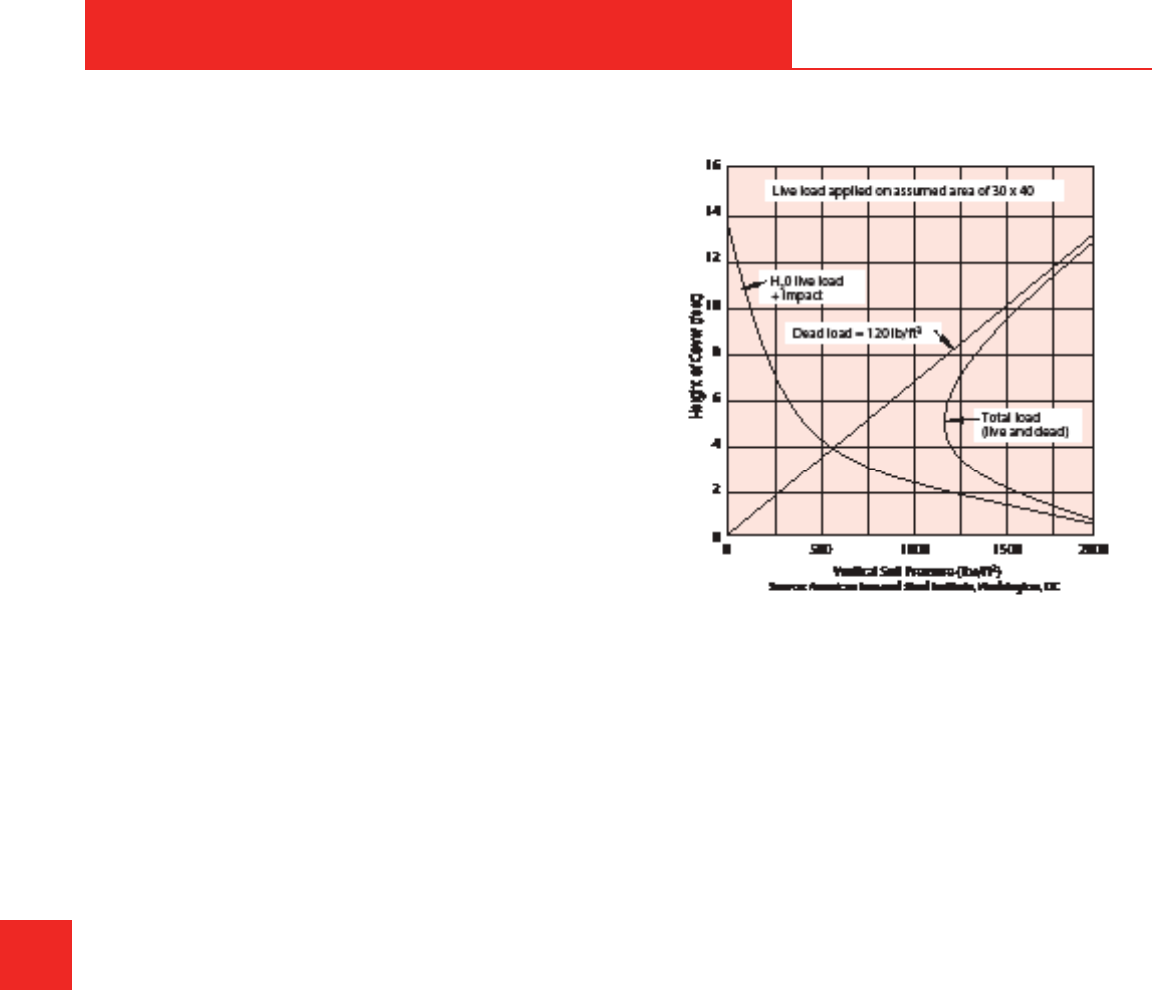

EXTERNAL PRESSURE

CALCULATIONS

C

BASIC CALCULATIONS

EXTERNAL PRESSURE

Example:

PPR pipe SDR33

40°C, 25 years

EC = 220N/mm

2

(creep modulus curve - page x)

Outside diameter da = 110 mm

Wall thickness = 3.4 mm

Additional safety factor 2.0 (minimum security factor for

stability calculation)

C-5

Pk

=

10 • EC

•

(

s

)

3

(C-13)

ȝ

2

)

r

m

Where:

Pk

= Critical buckling pressure [bar]

EC

= Creep modulus [N/mm

2

] for t = 25a

ȝ = Transversal contraction factor (for thermoplastics,

generally 0.38)

s = Wall thickness [mm]

r

m

= Medium pipe radius [mm]

In certain cases, piping systems are exposed to

external pressure:

-Installation in water or buried below groundwater table

-Systems for vacuum e.g., suction pipes

The buckling tension can then be calculated directly:

Pk

=

10 • EC

(

s

)

3

=(C-14)

ȝ

2

)r

m

=

10 • 220

(

3.4

)

3

=0.17

4 • (1 - 0.4

2

) 53.3

Pk

=

0.17

=0.085

2.0

ı

k

=

Pk •

r

m

= 0.085 •

53.3

= 1.33 (C-16)

s 3.4

ASAHI/AMERICA

Rev. 2013-A

655 Andover Street, Lawrence, MA 02148 • Tel: 800-343-3618, 781-321-5409

Fax: 800-787-6861 • https://www.asahi-america.com • Email: [email protected]

Section D

SYSTEM CHARTS

Contents

Pressure Curve Graphs ..........D-2

Creep Curves ..................D-12

Vacuum Pressure Charts ........D-17

Abrasion Resistance ............D-18

General Chemical Resistance ....D-19

Surface Roughness .............D-22

Production and Packaging .......D-23

Storage and Transportation ......D-24

Installation ....................D-27

D-1

ASAHI/AMERICA

Rev. 2013-A

655 Andover Street, Lawrence, MA 02148 • Tel: 800-343-3618, 781-321-5409

Fax: 800-787-6861 • https://www.asahi-america.com • Email: [email protected]

Pressure curve for pipes out of PE100

(acc. to EN ISO 15494, supplement B)

D

SYSTEM CHARTS

PRESSURE CURVE GRAPHS

D-2

Table D-2. Pressure Curve PE100

ASAHI/AMERICA

Rev. 2013-A

655 Andover Street, Lawrence, MA 02148 • Tel: 800-343-3618, 781-321-5409

Fax: 800-787-6861 • https://www.asahi-america.com • Email: [email protected]

Permissible component operating pressures p

B

for PE100,

depending on temperature and operation period.

In the table below, the data applies to water. They were determined from the

FUHHSFXUYHWDNLQJLQWRDFFRXQWDVDIHW\FRHႈFLHQWRI&

D

SYSTEM CHARTS

D-3

PRESSURE CURVE GRAPHS

Table D-3. Permissible Component Operating Pressure PE100

ASAHI/AMERICA

Rev. 2013-A

655 Andover Street, Lawrence, MA 02148 • Tel: 800-343-3618, 781-321-5409

Fax: 800-787-6861 • https://www.asahi-america.com • Email: [email protected]

Pressure curve for pipes out of PPH

(acc. to EN ISO 15494, supplement C)

D

SYSTEM CHARTS

PRESSURE CURVE GRAPHS

D-4

Table D-4. Pressure Curve PPH

ASAHI/AMERICA

Rev. 2013-A

655 Andover Street, Lawrence, MA 02148 • Tel: 800-343-3618, 781-321-5409

Fax: 800-787-6861 • https://www.asahi-america.com • Email: [email protected]

Permissible component operating pressures p

B

for PPH,

depending on temperature and operation period.

In the table below, the data applies to water. They were determined from the

FUHHSFXUYHWDNLQJLQWRDFFRXQWDVDIHW\FRHႈFLHQWRI&& IURPXQGHU

&& IURPXQGHU&& IURP&

D

SYSTEM CHARTS

D-5

PRESSURE CURVE GRAPHS

Table D-5. Permissible Component Operating Pressure PPH

ASAHI/AMERICA

Rev. 2013-A

655 Andover Street, Lawrence, MA 02148 • Tel: 800-343-3618, 781-321-5409

Fax: 800-787-6861 • https://www.asahi-america.com • Email: [email protected]

Pressure curve for pipes out of PPR

(acc. to EN ISO 15494, supplement C)

D

SYSTEM CHARTS

PRESSURE CURVE GRAPHS

D-6

Table D-6. Pressure Curve PPR

ASAHI/AMERICA

Rev. 2013-A

655 Andover Street, Lawrence, MA 02148 • Tel: 800-343-3618, 781-321-5409

Fax: 800-787-6861 • https://www.asahi-america.com • Email: [email protected]

Permissible component operating pressures p

B

for PPR,

depending on temperature and operation period.

In the table below, the data applies to water. They were determined from the

FUHHSFXUYHWDNLQJLQWRDFFRXQWDVDIHW\FRHႈFLHQWRI& 'XHWRWKH

GLႇHUHQWPHFKDQLFDOSURSHUWLHVRIWKHVSHFL¿FPDWHULDO33VHOWKHPD[LPXP

RSHUDWLQJSUHVVXUHKDVWREHUHGXFHGWRSHUFHQW

D

SYSTEM CHARTS

D-7

PRESSURE CURVE GRAPHS

Table D-7. Permissible Component Operating Pressure PPR

ASAHI/AMERICA

Rev. 2013-A

655 Andover Street, Lawrence, MA 02148 • Tel: 800-343-3618, 781-321-5409

Fax: 800-787-6861 • https://www.asahi-america.com • Email: [email protected]

Pressure curve for pipes out of PVDF

(acc. to EN ISO 10931, supplement A)

D

SYSTEM CHARTS

PRESSURE CURVE GRAPHS

D-8

Table D-8. Pressure Curve PVDF

ASAHI/AMERICA

Rev. 2013-A

655 Andover Street, Lawrence, MA 02148 • Tel: 800-343-3618, 781-321-5409

Fax: 800-787-6861 • https://www.asahi-america.com • Email: [email protected]

Permissible component operating pressures p

B

for PVDF,

depending on temperature and operation period.

In the table below, the data applies to water. They were determined from the

FUHHSFXUYHWDNLQJLQWRDFFRXQWDVDIHW\FRHႈFLHQWRI&

D

SYSTEM CHARTS

D-9

PRESSURE CURVE GRAPHS

Table D-9. Permissible Component Operating Pressure PVDF

ASAHI/AMERICA

Rev. 2013-A

655 Andover Street, Lawrence, MA 02148 • Tel: 800-343-3618, 781-321-5409

Fax: 800-787-6861 • https://www.asahi-america.com • Email: [email protected]

Pressure curve for pipes out of E-CTFE

(acc. to DVS 2205-1, supplement 18)

D

SYSTEM CHARTS

PRESSURE CURVE GRAPHS

Table D-10. Pressure Curve E-CTFE

D-10

ASAHI/AMERICA

Rev. 2013-A

655 Andover Street, Lawrence, MA 02148 • Tel: 800-343-3618, 781-321-5409

Fax: 800-787-6861 • https://www.asahi-america.com • Email: [email protected]

Permissible component operating pressures p

B

for E-CTFE,

depending on temperature and operation period.

In the table below, the data applies to water. They were determined from the

FUHHSFXUYHWDNLQJLQWRDFFRXQWDVDIHW\FRHႈFLHQWRI&

D

SYSTEM CHARTS

D-11

PRESSURE CURVE GRAPHS

Table D-11. Permissible Component Operating Pressure E-CTFE

ASAHI/AMERICA

Rev. 2013-A

655 Andover Street, Lawrence, MA 02148 • Tel: 800-343-3618, 781-321-5409

Fax: 800-787-6861 • https://www.asahi-america.com • Email: [email protected]

Creep modulus curves for PE100

(acc. to DVS 2205, part 1)

Figure D-1. Creep modulus curve for PE100 at 1 year

Figure D-3. Creep modulus curve for PE100 at 25

years

Figure D-2. Creep modulus curve for PE100 at 10

years

Reducing the creep modulus

In the above diagrams, the calculated creep modulus

VWLOOKDVWREHUHGXFHGE\DVDIHW\FRHႈFLHQWRIIRU

stability calculations.

,QÀXHQFHVE\FKHPLFDODWWDFNRUE\HFFHQWULFLW\DQG

unroundness must be taken into account separately.

D-12

ASAHI/AMERICA

Rev. 2013-A

D

SYSTEM CHARTS

CREEP CURVES

655 Andover Street, Lawrence, MA 02148 • Tel: 800-343-3618, 781-321-5409

Fax: 800-787-6861 • https://www.asahi-america.com • Email: [email protected]

Creep modulus curves for PPH

(acc. to DVS 2205, part 1)

Figure D-4. Creep modulus curve for PPH at 1 year

Figure D-6. Creep modulus curve for PPH at 25

years

Figure D-5. Creep modulus curve for PPH at 10

years

Reducing the creep modulus

In the above diagrams, the calculated creep modulus

VWLOOKDVWREHUHGXFHGE\DVDIHW\FRHႈFLHQWRIIRU

stability calculations.

,QÀXHQFHVE\FKHPLFDODWWDFNRUE\HFFHQWULFLW\DQG

unroundness must be taken into account separately.

D-13

ASAHI/AMERICA

Rev. 2013-A

D

SYSTEM CHARTS

CREEP CURVES

655 Andover Street, Lawrence, MA 02148 • Tel: 800-343-3618, 781-321-5409

Fax: 800-787-6861 • https://www.asahi-america.com • Email: [email protected]

Creep modulus curves for PPR/PPB

(acc. to DVS 2205, part 1)

Figure D-7. Creep modulus curve for PPR/PPB at 1

year

Figure D-9. Creep modulus curve for PPR/PPB at

25 years

Figure D-8. Creep modulus curve for PPR/PPB at 10

years

Reducing the creep modulus

In the above diagrams, the calculated creep modulus

VWLOOKDVWREHUHGXFHGE\DVDIHW\FRHႈFLHQWRIIRU

stability calculations.

,QÀXHQFHVE\FKHPLFDODWWDFNRUE\HFFHQWULFLW\DQG

unroundness must be taken into account separately.

D-14

ASAHI/AMERICA

Rev. 2013-A

D

SYSTEM CHARTS

CREEP CURVES

655 Andover Street, Lawrence, MA 02148 • Tel: 800-343-3618, 781-321-5409

Fax: 800-787-6861 • https://www.asahi-america.com • Email: [email protected]

Creep modulus curves for PVDF

(acc. to DVS 2205, part 1)

Reducing the creep modulus

In the above diagrams, the calculated creep modulus

VWLOOKDVWREHUHGXFHGE\DVDIHW\FRHႈFLHQWRIIRU

stability calculations.

,QÀXHQFHVE\FKHPLFDODWWDFNRUE\HFFHQWULFLW\DQG

unroundness must be taken into account separately.

Figure D-10. Creep modulus curves for PVDF at 1,

10, and 25 years

D-15

ASAHI/AMERICA

Rev. 2013-A

D

SYSTEM CHARTS

CREEP CURVES

655 Andover Street, Lawrence, MA 02148 • Tel: 800-343-3618, 781-321-5409

Fax: 800-787-6861 • https://www.asahi-america.com • Email: [email protected]

Creep modulus curves for E-CTFE

(acc. to DVS 2205, part 1)

Reducing the creep modulus

In the above diagrams, the calculated creep modulus

VWLOOKDVWREHUHGXFHGE\DVDIHW\FRHႈFLHQWRIIRU

stability calculations.

,QÀXHQFHVE\FKHPLFDODWWDFNRUE\HFFHQWULFLW\DQG

unroundness must be taken into account separately.

Figure D-11. Creep modulus curves for E-CTFE

D-16

ASAHI/AMERICA

Rev. 2013-A

SYSTEM CHARTS

CREEP CURVES

D

655 Andover Street, Lawrence, MA 02148 • Tel: 800-343-3618, 781-321-5409

Fax: 800-787-6861 • https://www.asahi-america.com • Email: [email protected]

VACUUM PRESSURE CHARTS

Permissible vacuum pressures for PE100, PPH and PPR, PVDF, Ventilation Pipes - our of PPH

and PE, PVDF - vent

3OHDVHVHHSURGXFWVSHFL¿FDWLRQVRQZZZDVDKLDPHULFDFRP

D-17

ASAHI/AMERICA

Rev. 2013-A

D

SYSTEM CHARTS

VACUUM PRESSURE CHARTS

655 Andover Street, Lawrence, MA 02148 • Tel: 800-343-3618, 781-321-5409

Fax: 800-787-6861 • https://www.asahi-america.com • Email: [email protected]

ABRASION RESISTANCE

Behavior with Abrasive Fluids

In principle, thermoplastic pipes are better suited for

WKHFRQYH\LQJRIÀXLGVROLGPL[WXUHVWKDQIRULQVWDQFH

concrete pipes or steel pipes. We have already had

SRVLWLYHH[SHULHQFHVIRUGLႇHUHQWDSSOLFDWLRQV

,QWKH7HFKQLVFKH+RFKVFKXOH'DUPVWDGWGHYHORSHG

method, a 1 m long half-pipe is tilted with a frequency of

0.18 Hz. The local deduction of the wall thickness after

a certain loading time is regarded as a measure of the

abrasion.

The advantage of thermoplastic pipes for the

transportation of solids in open channels can clearly be

seen from the test result.

0HGLXPVLOLFDVDQGJUDYHOZDWHUPL[WXUH

6LOLFDJUDYHOYROXPHJUDLQVL]HXSWRPP

Figure D-12. Abrasion behavior according to

Darmstadt method

In a more practical test, the medium is pumped through

pipe samples which are built into a piping system. One

reason to check the abrasion behavior of such a system

is to determine the amount of time until the formation

of a hole. As can be seen from the above diagram,

WKHUPRSODVWLFSLSHVLQWKLVFDVH3(SLSHVKDYHEHHQ

DSSOLHG33SLSHVZLOODFKLHYHWKHVDPHRUVOLJKWO\EHWWHU

UHVXOWVKDYHDQHVVHQWLDODGYDQWDJHFRPSDUHGWRVWHHO

pipes.

)RUFRQYH\LQJRIGU\DEUDVLYHDFWLQJÀXLGV

polypropylene can only be applied conditionally. Only

HOHFWURFRQGXFWLEOHPDWHULDOVVKRXOGEHXVHGLH3(HO

335VHO335HOGXHWRDSRVVLEOHVWDWLFORDG

7KHXVHRIHDFKVLQJOHDSSOLFDWLRQKDVWREHFODUL¿HG

with our technical engineering department.

D-18

ASAHI/AMERICA

Rev. 2013-A

D

SYSTEM CHARTS

ABRASION RESISTANCE

655 Andover Street, Lawrence, MA 02148 • Tel: 800-343-3618, 781-321-5409

Fax: 800-787-6861 • https://www.asahi-america.com • Email: [email protected]

GENERAL CHEMICAL RESISTANCE

General Chemical Properties of PE & PP

In comparison to metals, where an attack of chemicals

leads to an irreversible chemical change in the material,

it’s largely physical processes of plastics which reduce

their utility value. Such physical changes include

swelling and solution processes, which can change

WKHFRPSRVLWLRQRIWKHSODVWLFVWKHUHE\DႇHFWLQJWKHLU

mechanical properties. Reducing factors have to be

taken into consideration in the design of facilities and

selection of parts in these cases.

3(DQG33DUHUHVLVWDQWDJDLQVWGLOXWHGVROXWLRQVRI

VDOWVDFLGVDQGDONDOLVLIWKHVHDUHQRWVWURQJR[LGL]LQJ