BITZER COMPRESSOR RECIPROCATING RETROFIT GUIDE

TECHNICAL INFORMATION

BA-101-2 AUS

BITZER COMPRESSOR RECIPROCATING RETROFIT GUIDE

The BITZER Group is the world’s largest independent manufacturer of refrigeration and air conditioning compressors with subsidiaries and production sites

for reciprocating, screw, scroll compressors and pressure vessels all over the globe.

BITZER ranks among the leading manufacturers of refrigerant compressors with the highest degree of reliability and product quality. Some 3,000 employees

in more than 90 countries stand behind this success, people who are dedicated to putting all of their energy into making sure that the temperature will be

perfect in the future too.

The compressor is the heart of any refrigeration or air conditioning system, it must beat dependably. For over 80 years, the name BITZER has stood for

worldwide leading compressor technology which gives you complete confidence in any refrigeration or air conditioning application.

The BITZER Compressor Reciprocating Retrofit Guide is an extension to our technical support. It has been created as an easy-to-use tool to compare the

major compressor brands and their models to the equivalent and latest BITZER models. We are positive that you will find this guide a handy tool whether

you are engineering, retrofitting an old system or replacing a compressor to the latest BITZER model.

BITZER, the heart of freshness.

1

- New valve plate design

2

- New cylinder head design -

less pulsation

3

- Optimized gas fl ow for

minimum pressure drop

4

- New piston and connecting

rod design

5

- Specially adapted highly

effi cient motor

EXPLANATION OF MODEL DESIGNATION

Index for number of cylinders

(double with tandem compressor)

Identifi cation letter for bore x stroke

Identifi cation letter for BITZER ECOLINE series

Code for centrifugal lubrication

Code for motor size

Identifi cation letter for ester oil charge

Motor code

4

N E S - 20 Y - 40P

E S - 20 Y - 40P4 N

E

4 N S - 20 Y - 40P

S

4 N E

- 20 Y - 40P

4 N E S

- 20 Y - 40P

20

4 N E S - 20

- 40P

Y

4 N E S - 20 Y -

40P

TABLE OF CONTENTS

5

// Page 6 - Compressor Comparison: 2KES-05Y..2HES-2Y // Page 22 - Compressor Comparison: 4JE-13Y..4HE-25Y

// Page 7 - Technical Data: 2KES-05Y..2HES-2Y // Page 23 - Compressor Comparison: 4GE-20Y..4GE-30Y

// Page 8 - Compressor Comparison: 2GES-2Y..2FES-3Y // Page 24 - Compressor Comparison: 4FE-25Y..4FE-35Y

// Page 9 - Technical Data: 2GES-2Y..2FES-3Y // Page 25 - Technical Data: 4JE-13Y..4FE-35Y

// Page 10 - Dimensional Drawings: 2KES-05Y..2FES-3Y // Page 26 - Dimensional Drawings: 4JE-13Y..4FE-35Y

// Page 11 - Compressor Comparison: 2EES-2Y..2CES-4Y // Page 27 - Dimensional Drawings: 4JE-13Y..4FE-35Y

// Page 12 - Technical Data: 2EES-2Y..2CES-4Y // Page 28 - Compressor Comparison: 6JE-22Y..6GE-40Y

// Page 13 - Dimensional Drawings: 2EES-2Y..2CES-4Y // Page 29 - Technical Data: 6JE-22Y..6GE-40Y

// Page 14 - Compressor Comparison: 4FES-3Y..4EES-6Y // Page 30 - Dimensional Drawings: 6JE-22Y..6GE-40Y

// Page 15 - Compressor Comparison: 4DES-5Y..4CES-9Y // Page 31 - Compressor Comparison: 6FE-40Y..6FE-50Y

// Page 16 - Technical Data: 4FES-3Y..4CES-9Y // Page 32 - Technical Data: 6FE-40Y..6FE-50Y

// Page 17 - Dimensional Drawings: 4FES-3Y..4CES-9Y // Page 33 - Dimensional Drawings: 6FE-40Y..6FE-50Y

// Page 18 - Compressor Comparison: 4VES-6Y..4TES-12Y // Page 34 - Compressor Comparison: 8GE-60Y..8FE-70Y

// Page 19 - Compressor Comparison: 4PES-10Y..4NES-20Y // Page 35 - Technical Data: 8GE-60Y..8FE-70Y

// Page 20 - Technical Data: 4VES-6Y..4NES-20Y // Page 36 - Dimensional Drawings: 8GE-60Y..8FE-70Y

// Page 21 - Dimensional Drawings: 4VES-6Y..4NES-20Y // Page 37 - Technical Data Explanations

2KES-05Y .. 2HES-2Y

Displacement at

1450 min

-1

(m

3

/h)

BITZER

BITZER

Former Models

Dorin Bock Frascold Copeland China Copeland DWM

4.06 2KES-05Y 2KC-05.2 H40CC

-

A05-4Y

-

DKM-50

H75CC DKM-5X

DKM-75

DKM-7X

DKM-100

5.21 2JES-07Y 2JC-07.2 H100CC HG12P/60-4 S A05-5Y

-

DKJ-75

A07-5Y DKJ-7X

A07-6Y DKJ-100

A1-6Y DKJ-10X

DKJ-150

DKJ-15X

6.51 2HES-1Y 2HC-1.2 H150CC HG12P/75-4 A1-7Y

-

DKSJ-100

2HES-2Y 2HC-2.2 HG12P/75-4 S A1.5-7Y DKSJ-10X

DKSJ-150

DKSJ-15X

BITZER COMPRESSOR COMPARISON

6

Pipe connections Electrical data

Compressor

type

Motor

version

Displacement

at 1450 min

-1

Number of

cylinders

Oil

charge Weight

DL

Discharge

line

SL

Suction

line

CR

- Steps -

Motor

connection

Max.

Operating

current

Max.

Power

consumption

(m³/h) dm³ kg mm inch mm inch %

①

Volt

②

Amp.

③

kW

③

2KES-05Y

1 4.06 2 1.0 43

12

½

16

⅝

-

/ Y

4.9/2.8 1.5

2JES-07Y 1 5.21 2 1.0 43 12 ½ 16 ⅝

220..240∆/

380..420Y/3/50 6.4/3.7 1.9

2HES-1Y

2

6.51 2 1.0

44

12½16⅝

265..290∆/

6.7/3.8 2.0

2HES-2Y

145

440..480Y/3/60

7.8/4.5 2.4

TECHNICAL DATA

2KES-05Y .. 2HES-2Y

7

Displacement at

1450 min

-1

(m

3

/h)

BITZER

BITZER

Former Models

Dorin Bock Frascold Copeland China Copeland DWM

7.58 2GES-2Y 2GC-2.2 H180CC HG12P/90-4 A1.5-8Y

-

DKL-150

HG12P/90-4 S DKL-15X

DKL-20X

9.54 2FES-2Y 2FC-2.2 H200CC HG12P/110-4 B1.5-9.1Y LA10-0200 DKSL-15X

2FES-3Y 2FC-3.2 H220CC HG12P/110-4 S B1.5-10.1Y

LA10-020E

DKSL-200

B2-10.1Y DKSL-20X

DLE-201

DLE-20X

2GES-2Y .. 2FES-3Y

BITZER COMPRESSOR COMPARISON

8

TECHNICAL DATA

Pipe connections Electrical data

Compressor

type

Motor

version

Displacement

at 1450 min

-1

Number

of

cylinders

Oil

charge Weight

DL

Discharge

line

SL

Suction

line

CR

- Steps -

Motor

connection

Max.

Operating

current

Max.

Power

consumption

(m³/h) dm³ kg mm inch mm inch %

①

Volt

②

Amp.

③

kW

③

2GES-2Y 1 7.58 2 1.0 45 12 ½ 16 ⅝

-

220..240∆/

8.7/5.0 2.7

2FES-2Y 2

9.54 2 1.0

45

12½16⅝

380..420Y/3/50

9.2/5.3

2.9

2FES-3Y 1

47

265..290∆/

10.7/6.1

3.4

440..480Y/3/60

2GES-2Y .. 2FES-3Y

9

DIMENSIONAL DRAWINGS

2KES-05Y .. 2FES-3Y

68

J

K

74

105

106

202

VIEW A

G

F

'/6/

/3

137)

+3

137)

VIEW B

D1 D

E

9

A

B

H

C

A

,7(0DQG

81)

,7(0

B

L

,7(0

0[

Connection positions

1 High pressure connection (HP)

2 Discharge gas temp. sensor (HP)

or CIC sensor

3 Low pressure connection (LP)

4 CIC System: spray nozzle (LP)

5 Oil fi ll plug

6 Oil drain

7 Oil fi lter (magnetic screw)

8 Oil return (oil separator)

9a Gas equalisation (parallel operation)

9b Oil equalisation (parallel operation)

10 Crankcase heater

11 Oil pressure connection +

12 Oil pressure connection -

16 Connection for oil monitoring

(oil sensor or differential oil pressure

switch “Delta-P”)

21 Connection for oil service valve

A B C D D1 E F G H J K L

mm mm mm mm mm mm mm mm mm mm mm mm

2KES-05Y, 2JES-07Y, 2HES-1Y, 2HES-2Y

343 220 273 208 65 162 148 37 242 247 32 232

2GES-2Y, 2FES-2Y, 2FES-3Y

10

2EES-2Y .. 2CES-4Y

Displacement at

1450 min

-1

(m

3

/h)

BITZER

BITZER

Former Models

Dorin Bock Frascold Copeland China Copeland DWM

11.40 2EES-2Y 2EC-2.2 H280CC HG22e/125-4 D2-11.1Y --

2EES-3Y 2EC-3.2 HG22e/125-4 S

13.40 2DES-2Y 2DC-2.2 - HG22e/160-4

D2-13.1Y LA20-0200 DLF-201

2DES-3Y 2DC-3.2 HG22e/160-4 S D3-13.1Y LA20-020E DLF-20X

LA20-0300 DLF-301

LA20-030E DLF-30X

DLJ-201

DLJ-20X

DLJ-301

DLJ-30X

16.20 2CES-3Y 2CC-3.2 H300CC HG22e/190-4 D2-15.1Y - D2DC-500

2CES-4Y 2CC-4.2 H350CC HG22e/190-4 S D3-15.1Y D2DC-50X

D3-16.1Y

D4-16.1Y

BITZER COMPRESSOR COMPARISON

11

TECHNICAL DATA

2EES-2Y .. 2CES-4Y

Pipe connections Electrical data

Compressor

type

Motor

version

Displacement

at 1450 min

-1

Number of

cylinders

Oil

charge Weight

DL

Discharge

line

SL

Suction

line

CR

- Steps -

Motor

connection

Max.

Operating

current

Max.

Power

consumption

(m³/h) dm³ kg mm inch mm inch %

①

Volt

②

Amp.

③

kW

③

2EES-2Y 2

11.4 2 1.5

68

16 ⅝ 22 ⅞

-

/ Y

10.4/6.0 3.3

2EES-3Y 1 71 13.4/7.5 3.8

2DES-2Y 2

13.4 2 1.5

68

16 ⅝ 22 ⅞

220..240∆/ 13.4/7.5 4.0

2DES-3Y 1 71

380..420Y/3/50 15.0/8.6 4.6

2CES-3Y 2

16.2 2 1.5

70

16 ⅝ 22 ⅞

265..290∆/ 15.8/9.1 5.0

2CES-4Y 1 70 440..480Y/3/60 17.4/10.0 5.6

12

DIMENSIONAL DRAWINGS

Connection positions

1 High pressure connection (HP)

2 Discharge gas temp. sensor (HP)

or CIC sensor

3 Low pressure connection (LP)

4 CIC System: spray nozzle (LP)

5 Oil fi ll plug

6 Oil drain

7 Oil fi lter (magnetic screw)

8 Oil return (oil separator)

9a Gas equalisation (parallel operation)

9b Oil equalisation (parallel operation)

10 Crankcase heater

11 Oil pressure connection +

12 Oil pressure connection -

16 Connection for oil monitoring

(oil sensor or differential oil pressure

switch “Delta-P”)

21 Connection for oil service valve

2EES-2Y .. 2CES-4Y

A B C D D1 E F G H J K L

mm mm mm mm mm mm mm mm mm mm mm mm

2EES-2Y, 2EES-3Y, 2DES-2Y, 2DES-3Y

398 259 307 223 85 198 167 42 266 275 37 262

2CES-3Y, 2CES-4Y

13

81

123

L

90

121

VIEW B

E

D D1

13

VIEW A

J K

G

B

A

C

H

F

A

6/

,7(0DQG

81)

B

241

,7(0

/3

137)

'/

+3

137)

,7(0

0[

Displacement at

1450 min

-1

(m

3

/h)

BITZER

BITZER

Former Models

Dorin Bock Frascold Copeland China Copeland DWM

18.10

4FES-3Y 4FC-3.2 H380CC

HG34e/215-4

D3-18.1Y LA40-0300 DLL-301

4FES-5Y 4FC-5.2 H403CC

HG34e/215-4 S

D4-18.1Y LA40-030E DLL-30X

D3-19.1Y LA40-0400 DLL-401

D4-19.1Y LA40-040E DLL-40X

Q4-20.1E D2DD-500

Q4-20.1Y D2DD-50X

22.70

4EES-4Y 4EC-4.2 H503CC

HG34e/255-4

Q4-21.1Y LA50-0400 D2SA-450 Air

4EES-6Y 4EC-6.2 H551CC

HG34e/255-4 S

Q5-21.1Y LA50-040E D2SA-45X Air

Q4-24.1E D2SA-450

Q4-24.1Y D2SA-45X

Q5-24.1Y D2SA-550

D2SA-55X

DLSG-401

DLSG-40X

D2DL-400 DC

D2DL-40X

D2DL-750

D2DL-75X

14

BITZER COMPRESSOR COMPARISON

4FES-2Y .. 4EES-6Y

Displacement at

1450 min

-1

(m

3

/h)

BITZER

BITZER

Former Models

Dorin Bock Frascold Copeland China Copeland DWM

26.80 4DES-5Y 4DC-5.2 H551CS HG34e/315-4 Q4-25.1Y 2SCW-0550 D2SC-550 Air

4DES-7Y 4DC-7.2 H701CC HG34e/315-4 S Q5-25.1Y 2SCW-055E D2SC-55X Air

Q7-25.1Y D2SC-550

Q5-28.1E D2SC-55X

Q5-28.1Y D2SC-650

Q7-28.1Y D2SC-65X

D2DB-500 DC

D2DB-50X

D2DB-750

D2DB-75X

32.50 4CES-6Y 4CC-6.2 H701CS HG34e/380-4 Q5-33.1E 2SKW-0750 D2SK-650

4CES-9Y 4CC-9.2 H751CC HG34e/380-4 S Q5-33.1Y 2SKW-075E D2SK-65X

Q7-33.1Y D3SA-750

S5-33Y D3SA-75X

S7-33Y D3DA-500 DC

D3DA-50X

D3DA-750

D3DA-75X

15

BITZER COMPRESSOR COMPARISON

4DES-5Y .. 4CES-9Y

TECHNICAL DATA

Pipe connections Electrical data

Compressor

type

Motor

version

Displacement

at 1450 min

-1

Number

of

cylinders

Oil

charge Weight

DL

Discharge

line

SL

Suction

line

CR

- Steps -

Motor

connection

Max.

Operating

current

Max.

Power

consumption

(m³/h) dm³ kg mm inch mm inch %

①

Volt

②

Amp.

③

kW

③

4FES-3Y 2

18.1 4 2.0

82

16 ⅝ 22 ⅞

50

/ Y 16.5/9.5 5.3

4FES-5Y 1 86 18.8/10.8 5.8

4EES-4Y 2

22.7 4 2.0

84

16 ⅝ 28 1⅛

21.2/12.2 6.9

4EES-6Y 1 86 220..240∆/ 23.7/13.6 7.6

4DES-5Y 2

26.8 4 2.0

86

22 ⅞ 28 1⅛

380..420Y/3/50 25.2/14.5 8.1

4DES-7Y 1 89 265..290∆/ 28.7/16.5 8.9

4CES-6Y 2

32.5 4 2.0

91

22 ⅞ 28 1⅛

440..480Y/3/60 30.8/17.7 9.7

4CES-9Y 1

91

35.1/20.2 11.3

16

4FES-3Y .. 4CES-9Y

DIMENSIONAL DRAWINGS

Connection positions

1 High pressure connection (HP)

2 Discharge gas temp. sensor (HP)

or CIC sensor

3 Low pressure connection (LP)

4 CIC System: spray nozzle (LP)

5 Oil fi ll plug

6 Oil drain

7 Oil fi lter (magnetic screw)

8 Oil return (oil separator)

9a Gas equalisation (parallel operation)

9b Oil equalisation (parallel operation)

10 Crankcase heater

11 Oil pressure connection +

12 Oil pressure connection -

16 Connection for oil monitoring

(oil sensor or differential oil pressure

switch “Delta-P”)

21 Connection for oil service valve

4FES-3Y .. 4CES-9Y

A B C D D1 E F G H J K L

mm mm mm mm mm mm mm mm mm mm mm mm

4FES-3Y, 4FES-5Y 432 309 347 293 75 198 221 42 313 361 37 306

4EES-4Y, 4EES-6Y 432 309 352 293 75 198 221 56 316 361 37 306

4DES-5Y 432 309 352 293 75 198 221 56 316 361 42 310

4DES-7Y, 4CES-6Y, 4CES-9Y 457 309 352 293 101 198 246 56 316 386 42 310

17

125

'/ 6/

,7(0DQG

81)

B

A

H

C

F

L

A

J

VIEW B

D1 D

E

13

VIEW A

137)

0[

+3

,7(0 ,7(0

12

B

241

G

K

/3

137)

Displacement at

1450 min

-1

(m

3

/h)

BITZER

BITZER

Former Models

Dorin Bock Frascold Copeland China Copeland DWM

34.70 4VES-6Y ---Q5-36.1Y -

-

4VES-7Y

4VCS-6.2 Q7-36.1Y

4VES-10Y 4VCS-10.2

41.30 4TES-8Y - H751CS HG4/465-4 S8-42E 3SC1-1000 D3SC-750

4TES-9Y 4TCS-8.2 H851CS HG4/465-4 S S8-42Y

3SC1-100E

D3SC-75X

4TES-12Y 4TCS-12.2 H1001CC S12-42Y D3SC-1000

D3SC-100X

D3DC-1000

D3DC-100X

D3DC-750 DC

D3DC-75X

18

BITZER COMPRESSOR COMPARISON

4VES-6Y .. 4TES-12Y

Displacement at

1450 min

-1

(m

3

/h)

BITZER

BITZER

Former Models

Dorin Bock Frascold Copeland China Copeland DWM

48.50 4PES-10Y - H1001CS HG4/555-4 S10-52E 3SS1-1500 D3DS-1000 DC

4PES-12Y 4PCS-10.2 H1501CC HG4/555-4 S S10-52Y

3SS1-150E

D3DS-100X

4PES-15Y 4PCS-15.2 S15-52Y D3DS-1500

D3DS-150X

D3SS-1000

D3SS-100X

D3SS-1500

D3SS-150X

56.20 4NES-12Y - H1501CS HG4/650-4 S12-56E 4SAH-2000 D4SA-1000

4NES-14Y 4NCS-12.2 H2001CC HG4/650-4 S S15-56Y

4SAH-200E

D4SA-100X

4NES-20Y 4NCS-20.2 S20.56Y D4SA-2000

V15-59E D4SA-200X

V15-59Y D4SF-1000

V20-59Y D4SF-100X

D4DA-100X

D4DA-2000

D4DA-200X

D4DF-1000 DC

D4DF-100X

19

BITZER COMPRESSOR COMPARISON

4PES-10Y .. 4NES-20Y

TECHNICAL DATA

Pipe connections Electrical data

Compressor

type

Motor

version

Displacement

at 1450 min

-1

Number

of

cylinders

Oil

charge Weight

DL

Discharge

line

SL

Suction

line

CR

- Steps -

Motor

connection

Max.

Operating

current

Max.

Power

consumption

(m³/h) dm³ kg mm inch mm inch %

①

Volt

②

Amp.

③

kW

③

4VES-6Y 3

34.7 4 2.6

129

22 ⅞ 28 1⅛

50

9.4 6

4VES-7Y

2

129 PW

④

16.6 11

4VES-10Y 1 139 19.9 12

4TES-8Y

3

41.3 4 2.6

134

28 1⅛ 35 1⅜

11.4 7

4TES-9Y 2 134 19.9 13

4TES-12Y 1 141 380..420YY/3/50 25.1 14

4PES-10Y 3

48.5 4 2.6

139

28 1⅛

35 1⅜ 440..480YY/3/60 12.9 8

4PES-12Y 2 139 35 1⅜ 22.7 14

4PES-15Y 1 147 42 1⅝ 28.2 16

4NES-12Y 3

56.2 4 2.6

141

28 1⅛

35 1⅜ 14.9 9

4NES-14Y 2 141 35 1⅜ 26.6 17

4NES-20Y 1 150 42

1⅝

33.2 19

20

4VES-6Y .. 4NES-20Y

DIMENSIONAL DRAWINGS

Connection positions

1 High pressure connection (HP)

2 Discharge gas temp. sensor (HP)

or CIC sensor

3 Low pressure connection (LP)

4 CIC System: spray nozzle (LP)

5 Oil fi ll plug

6 Oil drain

7 Oil fi lter (magnetic screw)

8 Oil return (oil separator)

9a Gas equalisation (parallel operation)

9b Oil equalisation (parallel operation)

10 Crankcase heater

11 Oil pressure connection +

12 Oil pressure connection -

16 Connection for oil monitoring

(oil sensor or differential oil pressure

switch “Delta-P”)

21 Connection for oil service valve

A B C D D1 E F G H J K L

mm mm mm mm mm mm mm mm mm mm mm mm

4VES-6Y, 4VES-7Y, 4VES-10Y 633 303 385 367 140 256 44 61 161 558 42 338

4TES-8Y, 4TES-9Y, 4TES-12Y 633 303 385 367 140 256 44 64 161 557 56 342

4PES-10Y, 4PES-12Y 633 303 385 367 140 256 44 64 161 557 56 342

4PES-15Y 658 303 385 367 162 256 48 110 173 582 56 342

4NES-12Y, 4NES-14Y 633 303 385 367 140 256 44 64 161 557 56 342

4NES-20Y 658 303 385 367 162 256 48 110 173 582 56 342

21

4VES-6Y .. 4NES-20Y

L

F

19

B

152

A

B

H

C

K

A

J

G

'/

,7(0DQG

137)

,7(0

137)

6/

300

5

142

,7(0

0[

,7(0

12

,7(0

0[

+3

137)

+3

137)

VIEW A

/3

81)

,7(0

137)

VIEW B

D D1

E

21

Displacement at

1450 min

-1

(m

3

/h)

BITZER

BITZER

Former Models

Dorin Bock Frascold Copeland China Copeland DWM

63.50 4JE-13Y - H1601CS HG5/725-4

---

4JE-15Y 4J-13.2 H2201CC HG5/725-4 S

4JE-22Y

4J-22.2

73.70 4HE-15Y - H2000CS HG5/830-4 V15-71E 4SLW-1500 D4SH-1500

4HE-18Y 4H-15.2 H2500CC HG5/830-4 S V15-71Y 4SLW-150E D4SH-150X

4HE-25Y 4H-25.2 V25-71Y 4SHH-2500 D4SH-2500

4SHH-250E

D4SH-250X

D4SL-1500

D4SL-150X

D4DH-150X

D4DH-2500

D4DH-250X

D4DL-1500 DC

D4DL-150X

22

BITZER COMPRESSOR COMPARISON

4JE-13Y .. 4HE-25Y

Displacement at

1450 min

-1

(m

3

/h)

BITZER

BITZER

Former Models

Dorin Bock Frascold Copeland China Copeland DWM

84.60 4GE-20Y - H2500CS HG5/945-4 V20-84E 4STW-2000 D6SA-3000

4GE-23Y 4G-20.2 H3000CC HG5/945-4 S V20-84Y

4STW-200E

D6SA-300X

4GE-30Y 4G-30.2 V30-84Y 4SJH-3000 D6SF-2000

4SJH-300E

D6SF-200X

D4SJ-2000

D4SJ-200X

D4SJ-3000

D4SJ-300X

D4ST-2000

D4ST-200X

D4DJ-200X

D4DJ-3000

D4DJ-300X

D4DT-2200 DC

D4DT-220X

23

BITZER COMPRESSOR COMPARISON

4GE-20Y .. 4GE-30Y

Displacement at

1450 min

-1

(m

3

/h)

BITZER

BITZER

Former Models

Dorin Bock Frascold Copeland China Copeland DWM

101.80 4FE-25Y - - - V25-103E 6SLW-2500 D6SH-2000

4FE-28Y V25-103Y 6SLW-250E D6SH-200X

4FE-35Y V35-103Y 6SHH-3500 D6SH-3500

Z25-106E

6SHH-350E D6SH-350X

Z25-106Y D6SL-2500

Z35-106Y D6SL-250X

D6DH-200X

D6DH-3500

D6DH-350X

D6DL-2700 DC

D6DL-270X

24

BITZER COMPRESSOR COMPARISON

4FE-25Y .. 4FE-35Y

TECHNICAL DATA

Pipe connections Electrical data

Compressor

type

Motor

version

Displacement

at 1450 min

-1

Number

of

cylinders

Oil

charge Weight

DL

Discharge

line

SL

Suction

line

CR

- Steps -

Motor

connection

Max.

Operating

current

Max.

Power

consumption

(m³/h) dm³ kg mm inch mm inch %

①

Volt

②

Amp.

③

kW

③

4JE-13Y 3

63.5 4 4.0

179

28 1⅛ 42 1⅝

18.8 11

4JE-15Y 2 190 30.8 19

4JE-22Y 1 190 37.2 21

4HE-15Y 3

73.7 4 4.0

183

28 1⅛

42 1⅝

PW 21.4 13

4HE-18Y 2 190 42 1⅝ 36.7 22

4HE-25Y 1 194 54 2⅛ 50 380..420YY/3/50 44 25

4GE-20Y 3

84.6 4 4.5

192

28 1⅛ 54 2⅛

440..480YY/3/60 24.6 16

4GE-23Y 2 192 43.9 27

4GE-30Y 1 206 51.2 28

4FE-25Y 3

101.8 4 4.5

196

28 1⅛ 54 2⅛

30.5 19

4FE-28Y 2 207 52.8 31

4FE-35Y 1 207 62.1 35

25

4JE-13Y .. 4FE-35Y

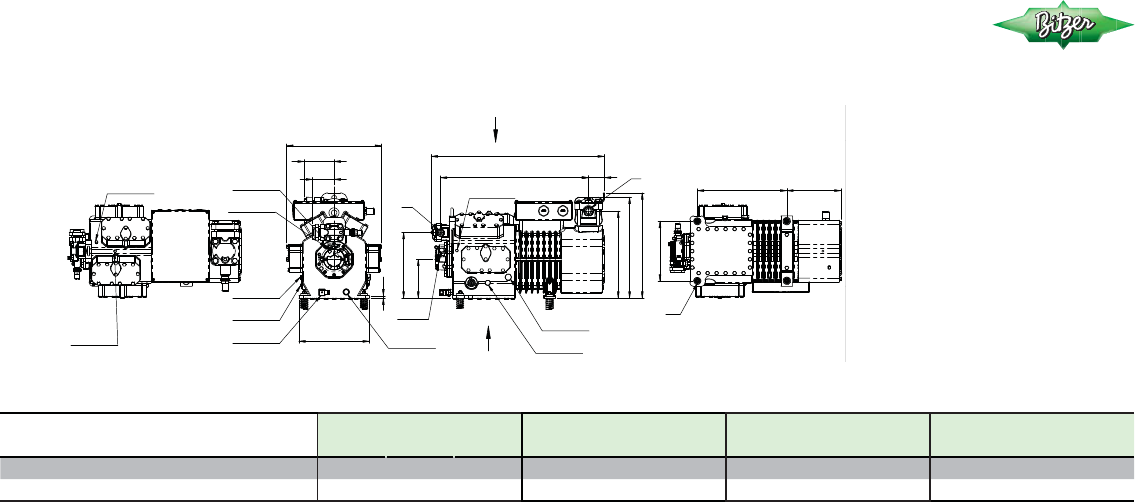

DIMENSIONAL DRAWINGS

Connection positions

1 High pressure connection (HP)

2 Discharge gas temp. sensor (HP)

or CIC sensor

3 Low pressure connection (LP)

4 CIC System: spray nozzle (LP)

5 Oil fi ll plug

6 Oil drain

7 Oil fi lter (magnetic screw)

8 Oil return (oil separator)

9a Gas equalisation (parallel operation)

9b Oil equalisation (parallel operation)

10 Crankcase heater

11 Oil pressure connection +

12 Oil pressure connection -

16 Connection for oil monitoring

(oil sensor or differential oil pressure

switch “Delta-P”)

21 Connection for oil service valve

26

B

C

VIEW B

D

E

D1

21

VIEW A

+3

137)

/3

137)

,7(0

137)

12

360

G

,7(0

137)

,7(0

81)

,7(0E

137)

,7(0D

137)

,7(0

81)

,7(0DQG

0[

+3

137)

A

B

A

J

F

H

L

K

157

6/

,7(0

137)

,7(0

137)

'/

,7(0

0[

4JE-13Y .. 4FE-35Y

DIMENSIONAL DRAWINGS

A B C D D1 E F G H J K L

mm mm mm mm mm mm mm mm mm mm mm mm

4JE-13Y, 4JE-15Y 688 456 452 381 151 305 66 110 361 501 56 362

4JE-22Y 688 456 452 381 151 305 66 110 361 501 56 362

4HE-15Y, 4HE-18Y

688 456 452 381 151 305 66 110 361 501 56 362

4HE-25Y

737 456 452 381 200 305 87 127 377 549 56 362

4GE-20Y, 4GE-23Y 706 456 452 381 169 305 76 127 377 519 56 362

4GE-30Y

737 456 452 381 200 305 87 127 377 549 56 362

4FE-25Y, 4FE-28Y

737 456 452 381 200 305 87 127 377 549 56 362

4FE-35Y 737 456 452 381 200 305 87 127 377 549 56 362

27

4JE-13Y .. 4FE-35Y

BITZER COMPRESSOR COMPARISON

Displacement at

1450 min

-1

(m

3

/h)

BITZER

BITZER

Former Models

Dorin Bock Frascold Copeland China Copeland DWM

95.30 6JE-22Y -

-

HG6/1080-4 V25-93Y

--

6JE-25Y 6J-22.2 HG6/1080-4 S V32-93Y

6JE-33Y 6J-33.2

110.50 6HE-25Y - H3000CS HG6/1240-4 -

--

6HE-28Y 6H-25.2 H3500CC HG6/1240-4 S

6HE-35Y

6H-35.2

126.80 6GE-30Y -i H3500CS HG6/1410-4 Z30-126E 6STW-3200 D6SJ-3000

6GE-34Y 6G-30.2 H4000CC HG6/1410-4 S Z30-126Y 6STW-320E D6SJ-300X

6GE-40Y 6G-40.2 Z40-126Y

6SJH-4000

D6SJ-4000

6SJH-400E

D6SJ-400X

D6ST-3200

D6ST-320X

D6DJ-300X

D6DJ-4000

D6DJ-400X

D6DT-3200 DC

D6DT-300X

28

6JE-22Y .. 6GE-40Y

TECHNICAL DATA

Pipe connections Electrical data

Compressor

type

Motor

version

Displacement

at 1450 min

-1

Number

of

cylinders

Oil

charge Weight

DL

Discharge

line

SL

Suction

line

CR

- Steps -

Motor

connection

Max.

Operating

current

Max.

Power

consumption

(m³/h) dm³ kg mm inch mm inch %

①

Volt

②

Amp.

③

kW

③

6JE-22Y 3

95.3 6 4.75

213

35 1⅜ 54 2⅛

26.6 16

6JE-25Y 2 228 46.4 27

6JE-33Y 1 231 53.2 30

6HE-25Y 3

110.5 6 4.75

224

35 1⅜ 54 2⅛

380..420YY/3/50 31.3 19

6HE-28Y 2 228 66 53.2 33

6HE-35Y 1 235 altern. 440..480YY/3/60 64.4 36

6GE-30Y 3

126.8 6 4.75

228

35 1⅜ 54 2⅛

33 38 23

6GE-34Y 2 228 PW

④

65.5 40

6GE-40Y 1 238 73.9 42

29

6JE-22Y .. 6GE-40Y

DIMENSIONAL DRAWINGS

Connection positions

1 High pressure connection (HP)

2 Discharge gas temp. sensor (HP)

or CIC sensor

3 Low pressure connection (LP)

4 CIC System: spray nozzle (LP)

5 Oil fi ll plug

6 Oil drain

7 Oil fi lter (magnetic screw)

8 Oil return (oil separator)

9a Gas equalisation (parallel operation)

9b Oil equalisation (parallel operation)

10 Crankcase heater

11 Oil pressure connection +

12 Oil pressure connection -

16 Connection for oil monitoring

(oil sensor or differential oil pressure

switch “Delta-P”)

21 Connection for oil service valve

30

B

C

,7(0

,7(0DQG

137)

,7(0

137)

,7(0

,7(0E

81)

137)

0[

137)

,7(0D

,7(0

81)

70 K G

12

360

0[

,7(0

137)

,7(0

'/

137)

,7(0

6/

A

B

L

J

H

F

158

A

137)

+3

,7(0

VIEW A

137)

+3

137)

/3

137)

VIEW B

D

D1

E

21

6JE-22Y .. 6GE-40Y

DIMENSIONAL DRAWINGS

A B C D D1 E F G H J K L

mm mm mm mm mm mm mm mm mm mm mm mm

6JE-22Y, 6JE-25Y 766 503 447 381 211 305 76 127 377 740 64 271

6JE-33Y 797 503 447 381 242 305 87 127 377 771 64 271

6HE-25Y, 6HE-28Y 766 503 447 381 211 305 76 127 377 740 64 271

6HE-35Y 797 503 447 381 242 305 87 127 377 771 64 271

6GE-30Y, 6GE-34Y 766 503 447 381 211 305 76 127 377 740 64 271

6GE-40Y 797 503 447 381 242 305 87 127 377 771 64 271

31

6JE-22Y .. 6GE-40Y

BITZER COMPRESSOR COMPARISON

Displacement at

1450 min

-1

(m

3

/h)

BITZER

BITZER

Former Models

Dorin Bock Frascold Copeland China Copeland DWM

151.60 6FE-40Y - H4500CS HG7/1620-4 W40-142Y 6SUW-4000 D8DH-400X

6FE-44Y 6F-40.2 H5000CC HG7/1620-4 S Z40-154E 6SUW-400E D8DH-5000

6FE-50Y 6F-50.2 HG7/1860-4 Z40-154Y 6SKH-5000 D8DH-500X

HG7/1860-4 S Z50-154Y 6SKH-500E D8DL-370X

D8SH-400X

D6SU-400X

D6SK-400X

D6SK-5000

D6SK-500X

32

6FE-40Y .. 6FE-50Y

TECHNICAL DATA

Pipe connections Electrical data

Compressor

type

Motor

version

Displacement

at 1450 min

-1

Number

of

cylinders

Oil

charge Weight

DL

Discharge

line

SL

Suction

line

CR

- Steps -

Motor

connection

Max.

Operating

current

Max.

Power

consumption

(m³/h) dm³ kg mm inch mm inch %

①

Volt

②

Amp.

③

kW

③

6FE-40Y 3

151.6 6 4.75

238

42 1⅝ 54 2⅛

66

altern.

33

380..420YY/3/50

440..480YY/3/60

PW

④

48.5 27

6FE-44Y 2 241 380..400YY/3/50 83.2 46

6FE-50Y 1 241 440..460YY/3/60 96.2 51

33

6FE-40Y .. 6FE-50Y

DIMENSIONAL DRAWINGS

Connection positions

1 High pressure connection (HP)

2 Discharge gas temp. sensor (HP)

or CIC sensor

3 Low pressure connection (LP)

4 CIC System: spray nozzle (LP)

5 Oil fi ll plug

6 Oil drain

7 Oil fi lter (magnetic screw)

8 Oil return (oil separator)

9a Gas equalisation (parallel operation)

9b Oil equalisation (parallel operation)

10 Crankcase heater

11 Oil pressure connection +

12 Oil pressure connection -

16 Connection for oil monitoring

(oil sensor or differential oil pressure

switch “Delta-P”)

21 Connection for oil service valve

A B C D D1 E F G H J K L

mm mm mm mm mm mm mm mm mm mm mm mm

6FE-40Y, 6FE-44Y 790 503 447 381 242 305 87 127 377 729 111 381

6FE-50Y

790 503 447 381 242 305 87 127 377 729 111 381

34

C

D1

B

VIEW B

E

D

21

VIEW A

+3

137)

/3

137)

+3

137)

,7(0

137)

K

360

G

12

,7(0

137)

,7(0DQG

0[

,7(0

81)

,7(0

137(

,7(0D

137(

,7(0E

137(

,7(0

81)

A

B

F

J

158

A

L

H

6/

,7(0

0[

,7(0

137)

'/

,7(0

137)

6FE-40Y .. 6FE-50Y

BITZER COMPRESSOR COMPARISON

35

Displacement at

1450 min

-1

(m

3

/h)

BITZER

BITZER

Former Models

Dorin Bock Frascold Copeland China Copeland DWM

185.00 8GE-60Y 8CG-60.2 H6000CC HG7/2110-4 W40-168Y

-

D8SJ-4500

HG7/2110-4 S W50-168Y D8SJ-450X

W50-187Y D8SJ-500X

W60-187Y D8SJ-6000

D8SJ-600X

D8DJ-500X

D8DJ-6000

D8DJ-600X

D8DT-450X

221.00 8FE-70Y 8FC-70.2

-

HG8/2470-4 W60-206Y

-

D8SK-600X

HG8/2470-4 S W70-206Y D8SK-7000

HG8/2830-4

W70-228Y

D8SK-700X

HG8/2830-4 S

W75-228Y

W75-240Y

W80-240Y

8GE-60Y .. 8FE-70Y

TECHNICAL DATA

36

Pipe connections Electrical data

Compressor

type

Motor

version

Displacement

at 1450 min

-1

Number

of

cylinders

Oil

charge Weight

DL

Discharge

line

SL

Suction line

CR

- Steps -

Motor

connection

Max.

Operating

current

Max.

Power

consumption

(m³/h) dm³ kg mm inch mm inch %

①

Volt

②

Amp.

③

kW

③

8GE-60(Y) 1

185 8 5.0

350

42 1⅝ 76 3⅛ 75 PW

④

113 63

altern.

380..420Y/3/50

8FE-70(Y) 1

221 8 5.0

374

54 2⅛ 76 3⅛ 50

440..480Y/3/60 139 78

8GE-60Y .. 8FE-70Y

DIMENSIONAL DRAWINGS

Connection positions

1 High pressure connection (HP)

2 Discharge gas temp. sensor (HP)

or CIC sensor

3 Low pressure connection (LP)

4 CIC System: spray nozzle (LP)

5 Oil fi ll plug

6 Oil drain

7 Oil fi lter (magnetic screw)

8 Oil return (oil separator)

9a Gas equalisation (parallel operation)

9b Oil equalisation (parallel operation)

10 Crankcase heater

11 Oil pressure connection +

12 Oil pressure connection -

16 Connection for oil monitoring

(oil sensor or differential oil pressure

switch “Delta-P”)

21 Connection for oil service valve

37

A B C D D1 E F G H J K L

mm mm mm mm mm mm mm mm mm mm mm mm

8GE-60Y 886 485 538 457 281 305 82 158 445 757 110 336

8FE-70Y 902 485 538 457 281 305 82 158 444 764 129 336

8GE-60Y .. 8FE-70Y

198

G

360

B

12

K

,7(0DQG

0[

,7(0

137)

,7(0

81)

,7(0

81)

,7(0

137)

,7(0

137)

A

B

A

C

L

H

J F

515

+3

137)

,7(0E

137)

,7(0D

137)

'/

6/

,7(0

0;

VIEW A

/3

137)

+3

137)

VIEW B

D1 D

E

TECHNICAL DATA EXPLANATIONS

CR Capacity control (option)

220..240 V/1/50/60 Hz

Tolerance (±10%) based on mean value of voltage range. Other voltages and electrical supplies upon request.

Data refer to 400 V/3/50 Hz at direct mains operation. For the selection of contactors, cables and fuses the max. operating current / max. power consumption must be

considered. See also

Contractors: Operational category AC3. Use thermal overload relay to limit max operating current.

PW: motor for Part Winding start Y/YY

• 4VES-6Y .. 6FE-50Y winding partition 50%/50%

• 8GE-50Y .. 8FE-70Y

/∆∆ winding partition 60%/40%

• For Part Winding start select motor contactors for approx. 60% of the max. operating current. Y/

∆ version upon request

Data for frequency inverter (FI) selection

- motor version 3 (R134a compressors):

based on 400 V/3/50 Hz supply voltage and use of 400 V/3/50 Hz standard motor for FI operation up to 70 Hz.

FI with motor version 1 and 2:

operation in the entire application range above 50 Hz requires motor with special voltage.

Selection upon request.

38

NOTES

39

BITZER Australia Pty Limited

Head Office

134 Dunheved Circuit,

St Marys, NSW 2760

Australia

tel +61 (2) 8801 9300

fax +61 (2) 9673 4698

www.bitzer.com.au