Advanced

Lightband

User’s Manual | 2003336C

Do not operate the Advanced Lightband (ALB) before reading this document. Do not operate the ALB beyond the

operating limits.

The ALB does not involve any high-energy liquid, solid fuels, or any material with inherently hazardous physical or

chemical properties.

spacesystems@rocketlabusa.com

rocketlabusa.com

2003336C Advanced Lightband User's Manual PSC by Rocket Lab

February 2023 https://www.rocketlabusa.com/space-systems/separation-systems/ Page 2 of 41

Table of Contents

1. REVISION HISTORY ................................................................................................................................................................................ 3

2. INTRODUCTION ....................................................................................................................................................................................... 4

3. PARAMETERS ......................................................................................................................................................................................... 6

4. ALB DESCRIPTION .................................................................................................................................................................................. 7

4.1 PART MARKING ....................................................................................................................................................................................... 7

4.2 TOLERANCE ON DIMENSIONS ................................................................................................................................................................... 7

4.3 MECHANICAL DESCRIPTION AND INTERFACE ............................................................................................................................................. 7

4.4 ELECTRICAL INTERFACE ........................................................................................................................................................................ 10

4.5 ACCESSIBILITY AND STAY-OUT ZONES .................................................................................................................................................... 11

4.6 MATERIALS AND SURFACE TREATMENTS................................................................................................................................................. 12

4.7 STIFFNESS ........................................................................................................................................................................................... 12

4.8 STIFFNESS OF ADJOINING STRUCTURES ................................................................................................................................................. 13

4.9 LINE LOAD LIMITS ................................................................................................................................................................................. 16

4.10 FATIGUE LIMITS & MASS-LOADED VIBRATION...................................................................................................................................... 17

4.11 FLATNESS AND PARALLELISM ............................................................................................................................................................ 18

4.12 SOFTRIDE AND ALB ......................................................................................................................................................................... 20

4.13 LIFECYCLE ....................................................................................................................................................................................... 20

4.14 ROTATION RATES ............................................................................................................................................................................. 21

4.15 SEPARATION VELOCITY AND SEPARATION SPRINGS ............................................................................................................................ 22

5. VERTICAL AND HORIZONTAL INTEGRATION TO ADJOINING VEHICLES ........................................................................................ 24

6. RELIABILITY, FAILURE MODES AND ANOMALY REPORTING .......................................................................................................... 26

6.1 FAILURE MODES, EFFECTS AND PREVENTATIVE ACTIONS ........................................................................................................................ 26

7. TESTING ................................................................................................................................................................................................. 27

7.1 TEST SUMMARY .................................................................................................................................................................................... 27

7.2 BUILD VERIFICATION ............................................................................................................................................................................. 27

7.3 COMPONENT RANDOM VIBRATION .......................................................................................................................................................... 28

7.4 THERMAL VACUUM ................................................................................................................................................................................ 28

7.5 SHOCK (CUSTOM TEST) ........................................................................................................................................................................ 29

7.6 SEPARATION TESTING (CUSTOM TEST) ................................................................................................................................................... 29

7.7 STRENGTH (CUSTOM TEST) ................................................................................................................................................................... 30

7.8 FATIGUE (CUSTOM TEST) ...................................................................................................................................................................... 30

8. SPECIFYING AN ALB ............................................................................................................................................................................ 31

8.1 DETERMINE STIFFNESS REQUIREMENTS .................................................................................................................................................. 31

8.2 DETERMINE STRENGTH REQUIREMENTS .................................................................................................................................................. 31

8.3 SELECT ALB BOLT CIRCLE DIAMETER..................................................................................................................................................... 31

8.4 COMPLETE VIRTUAL FIT CHECK AND PLAN LOGISTICS................................................................................................................................ 31

8.5 SEPARATION SWITCH QUANTITY (SW) .................................................................................................................................................... 31

8.6 SEPARATION CONNECTOR QUANTITY (SC) .............................................................................................................................................. 31

8.7 END USE (FLT OR EDU) ....................................................................................................................................................................... 31

8.8 SEPARATION SPRINGS........................................................................................................................................................................... 31

8.9 SPECIFYING ALB .................................................................................................................................................................................. 31

9. PURCHASING, DELIVERABLES, & SCHEDULE .................................................................................................................................. 32

9.1 PURCHASING AN ALB ............................................................................................................................................................................ 32

9.2 STANDARD DELIVERY SCHEDULE ........................................................................................................................................................... 32

9.3 ALB DELIVERABLES .............................................................................................................................................................................. 32

9.4 ALB STEP FILES .................................................................................................................................................................................. 32

9.5 ALB FINITE ELEMENT MODELS .............................................................................................................................................................. 32

9.6 CUSTOM UNITS ..................................................................................................................................................................................... 32

9.7 ACCESSORIES ...................................................................................................................................................................................... 32

9.7.1 Separation Connectors ............................................................................................................................................................... 32

9.7.2 Separation Switches ................................................................................................................................................................... 33

9.7.3 Separation Springs ..................................................................................................................................................................... 33

10. MANUFACTURING PROCESS .......................................................................................................................................................... 33

11. ALB TESTING AND PROCEDURES PERFORMED BY CUSTOMER ............................................................................................... 33

12. GROUND SUPPORT EQUIPMENT (GSE) ......................................................................................................................................... 34

13. WARRANTY AND GLOSSARY .......................................................................................................................................................... 36

13.1 WARRANTY ...................................................................................................................................................................................... 36

13.2 GLOSSARY ....................................................................................................................................................................................... 36

14. APPENDIX A: ALB ACCESSORIES .................................................................................................................................................. 37

14.1.1 ALB Separation Connector ......................................................................................................................................................... 37

14.1.2 ALB Separation Switch ............................................................................................................................................................... 38

14.1.3 Separation Springs ..................................................................................................................................................................... 38

14.1.4 Wiring Separation Switch and Separation Connector ................................................................................................................. 39

2003336C Advanced Lightband User's Manual PSC by Rocket Lab

February 2023 https://www.rocketlabusa.com/space-systems/separation-systems/ Page 3 of 41

1. Revision History

Rev. Issued

Written

By

Released

By

Change Description

- & A

See previous revisions

B

07Jun22

ML

CF

• Updated cover page with updated logo and graphic

• Typo fixes and grammatical changes throughout document

• Table 3-1: updated dim E stay out zone and latch up distance range, updated wording and

symbol Fws for clarity.

• Were Figure 4-25, 4-26 clarified stow screw torque at ‘ping’ for ALB24, increased first peak

torque to 22 in lb

• Section 8.2: added details PSC will request from customer to ensure strength requirement

compliance

• Section 8.8: reduced maximum number of springs for standard ALB to n/4

• Section 9.1: updated payment milestones

• Section 9.2: updated standard lead time

• Figure 9-1: updated number of springs for custom Lightband

• Was Section 14: updated checklist typos

• Table 14-3: updated wording and symbol Fws for clarity.

C

24Feb23

MH/Nirja

Dave

CMF

• Relocated Revision History to Section 1

• Removed Operation and Integration Section from procedure and creating two new documents

(PSC-RL document 3000355 ALB Operating Procedure and PSC-RL document 3000349 ALB

Pack-Unpack Procedure)

• Updated PSC references to PSC-RL

• Updated Section 2, features and benefits

• Updated references from Table 2-1 to Table 3-1

• Table 3-1Added row for default quantity for separation springs and updated storage

• Section 4.9: Additional line loading guidance

• Added Section 4.10 Fatigue Limits & Mass-Loaded Vibration

• Updated Section 4.13 Lifecycle

• Section 8.8: Updated language to reflect certain ALB sizes have default spring quantity of 4

• Section 9.6: Updated language to reflect certain ALB sizes have default spring quantity of 4

• Updated Section 13.1 Warranty

• Section 14: Updated attachment references to PSC-RL document 3000355

2003336C Advanced Lightband User's Manual PSC by Rocket Lab

February 2023 https://www.rocketlabusa.com/space-systems/separation-systems/ Page 4 of 41

2. Introduction

The Advanced Lightband (ALB) is a space vehicle separation system. It separates space vehicles from launch vehicles.

Figure 2-1: The ALB is offered in a range of sizes from 8.0 to 24.0-inch bolt circle diameter

The ALB is an advancement based on decades of work by Planetary Systems Corp by Rocket Lab (PSC-RL) manufacturing hundreds of separation

systems for commercial, government, private and university customers, in LEO, GEO and interplanetary orbits. The ALB is a patented, Commercial

Off-The-Shelf (COTS) technology. It is made and verified with materials and methods consistent with high-reliability space flight hardware.

Features and benefits

1. Easy to use Integrate in less than 30 minutes, training is simple, only two wires to initiate, looser flatness requirements

2. Reliable Thousands of separation tests in development and qualification environments prove reliability.

3. Stiffer and stronger A 30% increase in stiffness allows higher frequency 1

st

modes and reduces deflection.

4. All-inclusive product The ALB can accommodate integrated Separation Springs, Switches, and Connectors; and does not require

additional brackets or complex interface documentation. This reduces complexity, increasing reliability and decreasing mission cost.

5. No consumables, non-pyrotechnic Motor-driven eliminating need for consumable initiators.

6. Minimal reset time Separation tests can be repeated in minutes.

7. Lightweight The ALB is one third of the weight of a typical clamp band.

8. Low-height About one half of the height of a typical clamp band.

9. Precise initiation Critical separation timing of satellite swarms is enabled.

10. Low-shock Ideal for sensitive payloads.

11. Low tip-off Special testing can tune rotation rates to less than 1 deg/s

12. Higher Separation Velocity with increased precision. Special testing can tune delta V within 1.0 in/s. and larger springs produce

more separating velocity.

13. Backwards compatible and pyro-pulse compatible Accepts same connector and electrical pulse as MLB.

2003336C Advanced Lightband User's Manual PSC by Rocket Lab

February 2023 https://www.rocketlabusa.com/space-systems/separation-systems/ Page 5 of 41

Figure 2-2: An ALB attached to Starshine-4 during a pre-flight vibration test

Figure 2-3: Two ALB 24 Separate FX-2 and LTE-1 from SpaceX’s Transporter-2 using ALB 24

2003336C Advanced Lightband User's Manual PSC by Rocket Lab

February 2023 https://www.rocketlabusa.com/space-systems/separation-systems/ Page 6 of 41

3. Parameters

Table 3-1: Parameters

Sy m.

Tol.

D

8.000

11.732 13.000

15.000 18.250 19.848 23.250 24.000 ± 0.01

n 12

18

20 24 28 28 32 36

A 10.857 14.684 15.970 18.002 21.265 22.853 26.268 27.039 min

C 5.410

9.142

10.410 12.410 15.660 17.258 20.660 21.410 max

E

0.239 2.130

2.766 3.770 5.383 6.123 7.780 8.151 max

H

± 0.01

ds

.475 to

-.090

.475 to

-.090

.475 to

-.090

.475 to

-.090

.075 to

-.090

.075 to

-.135

.075 to

-.165

.075 to

-.175

Upper Assembly

1.24 1.78 1.96 2.20 2.71 3.00 3.52 3.55

Low er Assembly

3.24

4.27 4.61 5.25 6.00 6.14 6.91 7.44

Total

4.48

6.05 6.57

7.45 8.71 9.14 10.43 10.99

X

LB

1.03

1.04 1.05 1.04 1.05 1.07 1.07 1.06

Y

LB

0.58 0.85 0.92 1.00 1.12 1.19 1.28 1.26

Z

LB

0.11

0.08 0.08 0.07 0.06 0.06 0.05 0.05

X

LB

, Upper Assembly 1.60

1.61 1.61 1.61 1.61 1.61 1.60 1.61

Y

LB

, Upper Assembly 0.00

0.00 0.01 0.01 0.01 0.01 0.01 0.01

Z

LB

, Upper Assembly

0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00

X

LB

, Low er Assembly

0.82 0.81 0.81 0.81 0.81 0.80 0.80 0.80

Y

LB

, Low er Assembly

0.80 1.20 1.31 1.41 1.62 1.77 1.93 1.86

Z

LB

, Low er Assembly

0.15 0.12 0.11 0.10 0.08 0.08 0.07 0.07

I

XX

58 184

250 386 682 852 1,350 1,522

I

YY

29 87 117 179 316 393 624 705

I

ZZ

33

102 138 212 373 466 735 826

I

XX

, Upper Assembly 22

66 89 133 238 311 497 533

I

YY

, Upper Assembly

11 33 45 67 120 156 249 267

I

ZZ

, Upper Assembly

11 33 45 67 120 156 249 267

I

XX

, Low er Assembly 35 116 158 250 438 534 844 980

I

YY

, Low er Assembly

17

53 71 112 195 236 374 437

I

ZZ

, Low er Assembly 20

66 90 142 248 302 476 549

X

LB

(A xial) [lb

f

/bolt] Peq

Y

LB

or Z

LB

(Shear) [lb

f

/bolt] Q

2.34E+6

3.43E+6 3.81E+6 4.39E+6

5.34E+6 5.81E+6 6.80E+6 7.02E+6

1.82E+7

5.76E+7 7.83E+7

1.20E+8 2.17E+8 2.78E+8 4.47E+8 4.93E+8

0.004 0.007 0.008 0.008 0.009 0.011 0.013 0.013 max

0.003 0.005 0.006 0.006 0.007 0.008 0.010 0.010 max

V

Rw

Hm

Ip

Imin

Tp

Ti

Tsd

If r max

0.392 0.267

0.241 0.209 0.172 0.158 0.135 0.130

Ts

To

Pressure [Torr]

Spring Radius [in] Rs

4.788 6.701 7.344 8.360 9.992 10.786 12.493 12.878 ± 0.005

Energy per spring [J] e

Spring Constant [lbf/in] Ks

Force per spring, stow ed [lbf]

Fss

Force per spring, deployed [lbf] Fs d

Stroke [in] deltas ± 0.025

Weight Supported per Spring w hen stow ing [lb] Fw s max

Spring assembly + fastener [lbm]

Standard Qty. of Separation Springs [-] 3 3 4 3 4 4 4 3

Maximum Qty. of Separation Springs [-] Smax

6 9

10 12 14 14 16 18

X

0.0003 0.0023 0.0023 0.0023 0.0008 0.0008 0.0008 0.0008

Y 0.0002

0.0010 0.0011 0.0011 0.0024 0.0024 0.0024 0.0024

Z 0.0092 0.0008 0.0028 0.0028 0.0061 0.0061 0.0061 0.0061

Rc 4.724

6.637 7.280 8.296 9.928 10.722 12.429 12.814

5 8 9 11 13 13 15 17

Energy per separation connector [J] Kec

Spring Constant [lbf/in]

Kc

Force per connector, stow ed [lbf] Fs c

Force per connector, deployed [lbf]

Fdc

Stroke [in] dsc

Current, each pin, steady state, vacuum [A]

Is c v

Current, each pin, steady state, STP [A] Is c a

Pulsed current through pin [A] Ip v

Mated pin-pair contact resistance [Ohm] Rs c ± 0.02

Mated pair mass + fasteners [lbm] ± 0.02

Energy per separation sw itch [J] Kes

Spring Constant [lbf/in]

Ks

Force per sw itch, stow ed [lbf] Fsw

Force per sw itch, deployed [lbf]

Fds

Stroke [in] dsw ± 0.05

Current, steady state, vacuum [A] Is c v

Contact resistance [Ohm] Rs w

Mass + fasteners [lbm] ± 0.02

Lif e

Deployments [-]

100

Storage (Stow ed or Deployed) [year]

3

0.04

0.099

Separation

Sw itch

0.02

14.0

3.7

0.9

0.21

5.0

<0.025

0.058

1.9

0.110

3.00

5.00

5.00

Accessories

Separation

Springs

2.45

5.85

19.9

8.8

1.890

50.0

0.087

Max rotational

energy [J]

Connector and Sw itch Radius [in]

Max. sum of Sep. Connector and Sw itch Qty. [-]

Separation

Connector

0.001

38

5.1

No Fire Current [A]

0.02

Max resistance, through Lightband [Ohm]

<0.01

Thermal-

vacuum

Thermal resistance, X direction [°C/W]

Survival Temperature[°C]

-50 to +110

Operating Temperature[°C]

-40 to 90

Electrical

Initiation

<10-4

Time to Initiate [s]

0.005 to 0.035

Time to spin dow n [s]

>0.3

Free running current, maximum [A]

<0.2

Time to apply pow er [s]

0.1 to 1

± 25%

Stiffness about Y

LB

or Z

LB

[in∙lb

f

/rad]

Required f latness of adjoining structure if adjoining structure is

"flexible" [in] (see table 3-4)

Required f latness of adjoining structure if adjoining structure is

"stiff" [in] (see table 3-4)

Voltage, (Pin 1-4) [V]

24 to 32

Motor terminal resistance [Ohm]

5.9 to 11.4

Motor terminal inductance [mH]

0.746

Peak current [A]

5.4

Minimum supplied current to the ALB [A]

3.3

Loading &

Boundaries

Operating limit

Line Loads

1,720

646

Stiffness about X

LB

[lb

f

/in]

Latch-up distance [in]

Mas s

Properties

(Does not

include

accessories)

Mass [lb

m

]

± 5%

Center of

Mass [in]

± 0.1

Inertia

[lb

m

∙in

2

]

(Measured

about CM in

stow ed state)

± 10%

Dimensions

Stay-Out Dimensions [in]

2.100

Parameter

Value

Size

Bolt Circle Diameter [in]

Number of Fasteners

2003336C Advanced Lightband User's Manual PSC by Rocket Lab

February 2023 https://www.rocketlabusa.com/space-systems/separation-systems/ Page 7 of 41

4. ALB Description

4.1 Part Marking

Each ALB is marked with its assembly number and serial number in the vicinity of the DE-9 connector on the Upper Ring. The Upper and Lower

Rings are matched pairs, the serial number shall match.

4.2 Tolerance on Dimensions

Precision

Tolerance [unit]

x.xxx

± 0.005

x.xx

± 0.010

x.x

± 0.030

x

± 1.000

Table 4-1: PSC-RL distance tolerances

4.3 Mechanical Description and Interface

The coordinate system for the ALB is shown below. The +X

LB

axis originates from the Lower Ring bottom plane centered at the bolt pattern and

points towards the Upper Ring. The +Y

LB

axis passes through the center plane of the Stow Screw Hole (and DE-9 connector). Unless otherwise

noted, all axes in this document refer to the ALB coordinate system and all dimensions are given in inches.

Figure 4-1: Stowed ALB

2003336C Advanced Lightband User's Manual PSC by Rocket Lab

February 2023 https://www.rocketlabusa.com/space-systems/separation-systems/ Page 8 of 41

Figure 4-2: Separated ALB

2003336C Advanced Lightband User's Manual PSC by Rocket Lab

February 2023 https://www.rocketlabusa.com/space-systems/separation-systems/ Page 9 of 41

Figure 4-3: Origin, Deployed and Stowed Dimensions

2003336C Advanced Lightband User's Manual PSC by Rocket Lab

February 2023 https://www.rocketlabusa.com/space-systems/separation-systems/ Page 10 of 41

4.4 Electrical Interface

Figure 4-4: Schematic

A simple embodiment is one Separation Switch on the Upper Ring to enable the satellite when it separates. Not using a (second) Separation Switch

on the Lower Ring is only advisable if the launch service will have a video record of separation or another non-contact verification of separation.

Verification of separation is a critical means to help initiate a mission — managers know the satellite separated from the launch vehicle and is trying

to establish communication with controllers. 22 American Wire Gage (AWG) wire is sufficient in most cases to and through the ALB.

2003336C Advanced Lightband User's Manual PSC by Rocket Lab

February 2023 https://www.rocketlabusa.com/space-systems/separation-systems/ Page 11 of 41

4.5 Accessibility and Stay-out zones

Figure 4-5: Accessibility and Stay-out zones

Access for externally accessed features include the Stow Screw, the DE-9 connector to the initiator, the wire exits from the Separation Switch and

the Separation Connector and Spring Locks should be considered when joining the spacecraft to the launch vehicle and shipping container. Solar

panels, rocket nozzles and other appendages may block some access in some parts of vehicular operations. See Table 3-1 for stay-out zone

dimensions.

2003336C Advanced Lightband User's Manual PSC by Rocket Lab

February 2023 https://www.rocketlabusa.com/space-systems/separation-systems/ Page 12 of 41

4.6 Materials and Surface Treatments

All of the materials are low outgassing as defined by ASTM-E-595: total mass loss (TML) is less than 1.0% and a collected volatile condensable

materials (CVCM) is less than 0.1%. About ninety percent of the mass is Aluminum. There is no tungsten, zinc, tin, cadmium, or nylon. All of the

materials and surface treatments have flight heritage. The parts (motors, switches, connector pins, DE-9, fasteners) have flight heritage. The

surfaces of the ALB are conductive. The ALB is not sensitive to radiation. The ALB does not possess any integrated circuits or semi-conductors.

There are no diodes, capacitors or resistors. The ALB has no static-sensitive parts.

All parts in the primary load path are not affected by hydrazine, however the Springs, Separation Connectors, Separation Switches, Motor and

Wiring Harness are all not compatible with hydrazine and may be detrimentally damaged through exposure.

Part

Material

Surface treatment

Lower Ring Aluminum 7000 series

Chemical Film per MIL-DTL-5541, Class 3, Color

Gold

Upper Ring, Retaining Ring and Leaf

Pin

Aluminum 7000 series

Electroless Nickel per ASTM B733-15, Type IV, 5

to 9% P SC N/A Class 4

Leaf Aluminum 6000 or 7000 series

Electroless Nickel per ASTM B733-15, Type IV, 5

to 9% P SC N/A Class 4

Fasteners A-286 Passivation

Lubricant Braycote 601 EF w/ Molybdenum Disulfide -

Motor Copper, Neodymium, CRES Various

Initiator A286, 303, Nitronic 60, Titanium (0.02 lb.), Passivation

Springs

301, 302, 304 or music wire, Delrin (Acetal)

and Aluminum

Passivation, Chemical Film per MIL-DTL-5541,

Class 3, Color Gold

Separation Connectors

Gold, Vespel, Aluminum 6000 series, CRES,

copper

Electroless Nickel per ASTM B733-15, Type IV, 5

to 9% P SC N/A Class 4

Separation Switches and their brackets Aluminum, epoxy, copper

Chemical Film per MIL-DTL-5541, Class 3, Color

Gold (switch bracket)

Wiring Harness and DE-9 connector

Copper, Silver, Gold, ETFE, Kynar, Solder

(IPC J-STD-006), DAP, CRES

-

Table 4-2: Materials and Surface Treatments

4.7 Stiffness

Stiffness is a major design driver when determining which ALB size is required for a payload. Payload stack stiffness increases with the cube of the

ALB diameter (D

3

). For example, a 15-inch diameter ALB is about 6.6 times stiffer than an 8-inch diameter ALB but weighs less than twice as much.

Additionally, the first lateral mode frequency of the payload stack increases with the 3/2 power of ALB diameter (D

1.5

). Often, customers select the

smallest allowable ALB with the intent of saving mass. However, this can increase risk of mission failure due to unintended stack dynamics. Prudent

customers often use a larger ALB than required to gain stiffness margin. The small increase in ALB mass is more than offset by the need for a less

stiff (i.e., massive) space vehicle structure. Stiffness values are shown in Table 3-1. Higher fidelity stiffness estimations of the ALB can be

determined via FEM.

Figure 4-6: Larger diameter ALBs are stiffer and stronger than smaller diameters

2003336C Advanced Lightband User's Manual PSC by Rocket Lab

February 2023 https://www.rocketlabusa.com/space-systems/separation-systems/ Page 13 of 41

4.8 Stiffness of Adjoining Structures

In order to maximize the stiffness of the satellite stack including the ALB, engineers should design robust features in the structures adjoining the

ALB. As the analysis in Table 4-3 shows, thick flanges, small moment arms, and chamfers (or large radii) create much stiffer and lighter structures.

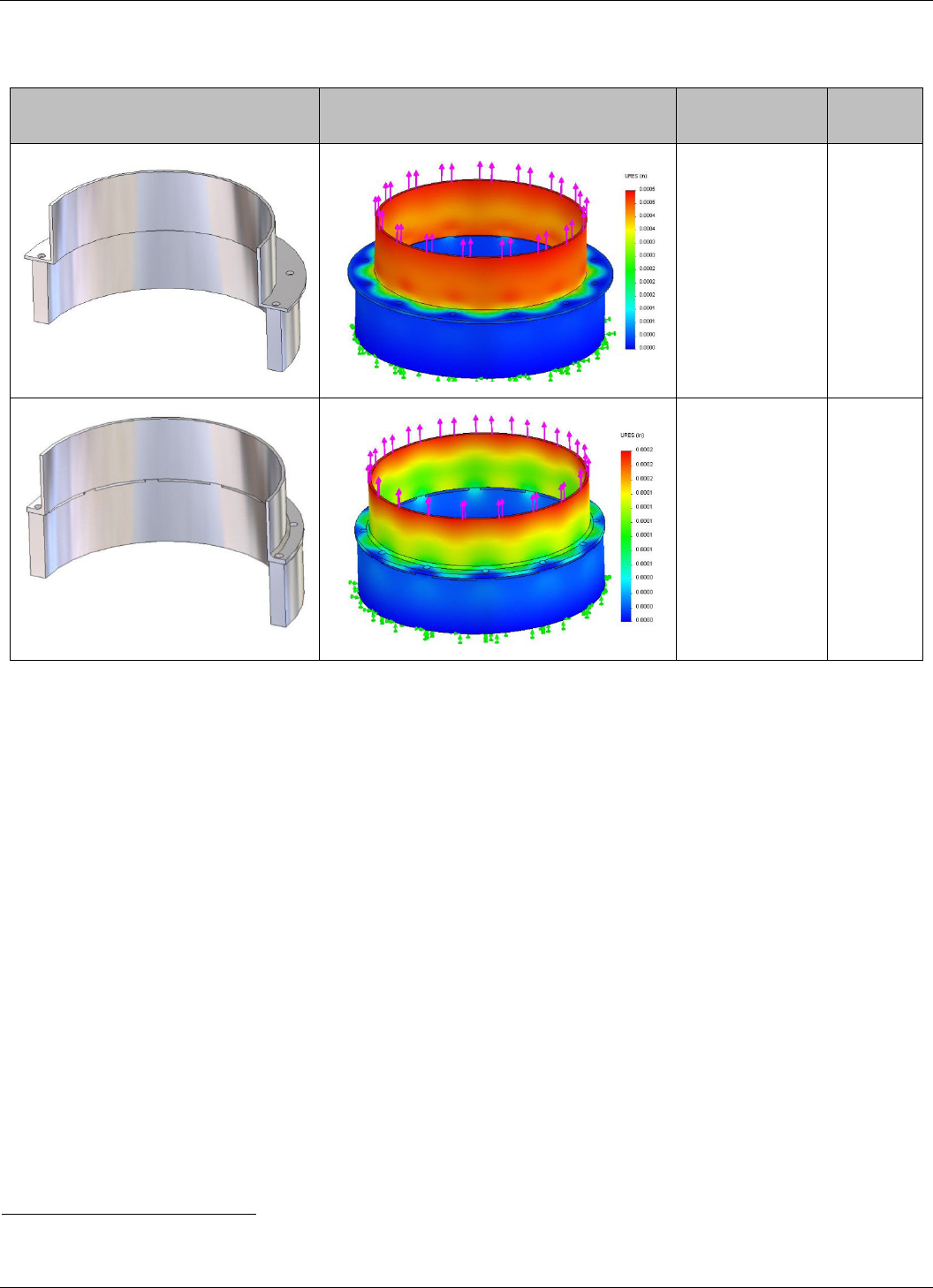

Design Deflection Plot Design Notes

Max

Deflection

Value [in]

• Flanges too thin

• Moment arms too

large

• No chamfer or

fillet

0.0005

• Thicker flanges

• Smaller moment

arms, but fits

fasteners

• Chamfer added

for stiffness

• No significant

increase in mass

0.0002

Table 4-3: Features of adjoining structure

1

The stiffness of flanges is important relative to overall stack stiffness. If the flange stiffness is too low, the first mode lateral frequency of the entire

stack can decrease detrimentally. For proper operation of the ALB, the flanges should be stiff enough to guarantee the preload of the ALB will not

excessively warp the adjoining structure and vice-versa.

The stiffness increase associated with straight load-paths is illustrated below. A straight load path can double the stiffness and increase lateral

frequencies by 40%.

Fasteners must be installed at every location in order to integrate the ALB. Do not skip a bolt as this will substantially decrease strength and stiffness

of the ALB.

The thermal extremes of the bolted joint often drive the selection of fasteners. Users anticipating temperatures beyond +10 to +50°C should examine

the preload changes associated with coefficient of thermal expansion (CTE) mismatch. In the past, missions on the Space Shuttle have driven

bolted joint design to extremes because joints are expected to survive landing loads at very low temperature (-40°C). NASA-STD-5020 document

outlines a thorough bolted joint analysis.

Stiffness is affected by bolted joints. A well designed bolted joint leads to greater stiffness and is less susceptible to slipping or gapping.

1

The lower cylinder represents a Lightband. The upper cylinder with flange represents an adjoining structure. The applied load is 1,000 lb. The

materials are aluminum.

2003336C Advanced Lightband User's Manual PSC by Rocket Lab

February 2023 https://www.rocketlabusa.com/space-systems/separation-systems/ Page 14 of 41

Figure 4-7: Straight load-paths from adjoining structures substantially increase stiffness

Figure 4-8: Structures with stiffest flange design. Moment arms in the flange are minimal, maximizing stiffness and strength

As noted in Table 3-1, there are two sets of required flatness for adjoining structure values. Though somewhat subjective, if the adjoining structure is

relatively stiff, the required flatness will be tighter than if the adjoining structure is relatively flexible. A relatively flexible structure will conform to the flat

interface better than a relatively stiff one.

The type of adjoining structure can also have an effect on operation and integration of the ALB. Users should be aware of the effects of their choice

of adjoining structure before integration and adequately plan for any likely issues. See following table.

2003336C Advanced Lightband User's Manual PSC by Rocket Lab

February 2023 https://www.rocketlabusa.com/space-systems/separation-systems/ Page 15 of 41

Table 4-4: Comparison of ALB adjoining structures

2003336C Advanced Lightband User's Manual PSC by Rocket Lab

February 2023 https://www.rocketlabusa.com/space-systems/separation-systems/ Page 16 of 41

4.9 Line Load Limits

Line loading in the X

LB

axis arises from loads in the X

LB

direction and moments about the Y

LB

or Z

LB

axis. Generally, the moments about Y

LB

and Z

LB

generate higher line loading than axial loads. In other words, lateral load cases are typically the limiting factor in strength margin.

Figure 4-9: Line loading forces

Each Leaf corresponds to thru holes for fastening to the adjoining structures. The thru-holes are sized for 0.25-inch socket head cap (SHC) screws.

PSC-RL analysis and tests have shown that the as-designed fastener hole size and spacing is optimum for ALB operation. All testing at PSC-RL is

performed with 0.25-inch fasteners because PSC-RL test cells have 0.25-28 UNF accepting threads.

Axial line loading arises from axial (X

LB

) and lateral (Y

LB

or Z

LB

) loading and moments about Y

LB

or Z

LB

, whereas shear line loading arises from lateral

(Y

LB

or Z

LB

) loading and moments about X

LB

. In flight, lateral loads tend to make the greatest contribution to line loading. Maximum lateral load and

axial load do not occur at the same location on the ALB and standard PSC-RL strength testing reflects this fact.

Note: PSC-RL documentation sometimes expresses line loading in terms of force/Leaf instead of force/bolt. ALB’s have 1 less Leaf than bolt, but the

difference in line load value from this computation method is accounted for in PSC-RL qualification testing. Thus, the terms force/Leaf and force/bolt

are interchangeable.

The equations below provide an approximation of the line loading for initial sizing purposes. They will not however account for peaking due to

stiffness variation of adjoining structures (e.g. base plate stiffening ribs, access cutouts, walls, etc.). They also do not account for non-uniform load

distribution resulting from significant lateral CG offsets. Customers should incorporate the ALB finite element model in their flight stack to determine

the actual load distribution around the ALB. This will expose peaking and inform any derating. Naturally customers should avoid structural

discontinuities to retain high line load margin.

Magnitude of maximum axial line load is given by Equation (1). Direction of maximum axial line load is the same as F

X

.

P

=

|

|

n

+

4

|

VX

|

nD

(1)

Where:

P

eq

is maximum axial line loading [force per bolt]

F

X

is axial force [force]

n is the number of fasteners in the bolt circle [-] (n is one more than the number of Leaves)

V is lateral force [force]

X is the distance from the ALB origin to the load application point in the x direction (typically the center of mass in X direction) [length]

D is the bolt circle diameter [length]

Magnitude of maximum shear line loading is given by Equation (2):

Q =

2

n

V +

|M

|

D

(2)

2003336C Advanced Lightband User's Manual PSC by Rocket Lab

February 2023 https://www.rocketlabusa.com/space-systems/separation-systems/ Page 17 of 41

Where:

Q is the maximum shear line load [force per bolt]

V is the lateral force [force]

n is the number of fasteners in the bolt circle [-] (n is one more than the number of Leaves)

D is the bolt

circle diameter [length]

M

X

is the maximum applied torsional moment about the X

LB

axis (typically negligible in-flight loading) [force x length]

The line load operating limits of P

eq

and Q in Table 3-1 were established by applying loads (Fx and V) to an ALB in qualification strength tests. The

computed line loading was reduced to establish the operating limits shown in Table 3-1. In the strength tests, the distribution of load is discontinuous

because the Stow Screw occupies the space of one Leaf. Therefore, the Leaves adjacent to the Stow Screw will carry a higher percentage of load.

Thus, in test, the actual line loading was higher. This peaking is naturally accounted for with equations 1 and 2.

Typically, customers launch spacecraft with a maximum line loading that is half of the operating limit because they are typically attempting to

maximize stiffness (which tends to produce lower line loading).

Figure 4-10: A round separation system and a square satellite can create high line loading

4.10 Fatigue Limits & Mass-Loaded Vibration

Fatigue failure is generally defined as failure due to cyclic loading. Fatigue failure is typically manifested in a flight stack as a loss of preload in

fasteners, a breakdown of surface treatments at separable interfaces, or cracking of materials. Fatigue can be induced by static, dynamic and

thermal environmental loads. Loading can be locally amplified when dissimilar structures (ex. round to square) are joined to the ALB. The ALB’s load

limits are based on quasi-static strength testing.

When derating the ALB’s maximum load capability from Table 3-1 consider all loading events including mass loaded random vibration, sine sweep,

sine burst and shock testing as well as flight environments. The customer shall use an equivalent fatigue damage approach to properly account for

the combined effects of all loading. See section 7.8 for qualification fatigue testing performed on the ALB. The line loads shown are axial.

Mass-loaded vibration will generate cyclic loading on the ALB dependent on the adjoining structure and payload stiffness and damping. This will

often result in loads far greater than those calculated in Section 4.9 using quasi-static load factors. Flight ALBs should not be used for mass-loaded

vibration testing. If mass-loaded vibration testing is required by the launch provider a waiver should be requested given the ALB’s qualification or an

EDU ALB shall be used. Further, all test and flight environments shall be accurately predicted using a finite element model of the ALB and payload.

During testing, the test results shall be continually compared to analytical predictions for sufficient agreement.

2003336C Advanced Lightband User's Manual PSC by Rocket Lab

February 2023 https://www.rocketlabusa.com/space-systems/separation-systems/ Page 18 of 41

4.11 Flatness and Parallelism

Prior to joining, the surfaces adjoining the ALB should be flat to the specification defined in Table 3-1.

Figure 4-11: An MLB attached to a launch vehicle cone and CAD model showing resulting stress peaking that occurs when adjoining two

warped surfaces

When the adjoining vehicles are extremely warped or surfaces are not parallel, an attempt to join the ALB to both adjoining structures may break or

damage the ALB. Joining an ALB to only one adjoining structure will generally not increase stress because separation systems are designed to be

more flexible than adjoining structures.

It may be tempting to design flexible features to attenuate stress exhibited in the warped structures that are joined. However, this can lead to an

unacceptably low stiffness and first mode frequency of the entire system. To achieve both a low stress and high stiffness system, flatness of the

adjoining structures must be controlled.

Isolation systems like Moog CSA Engineering’s SoftRide intentionally add flexibility to joints to attenuate response. Furthermore, isolation systems

offer an additional benefit in the substantial relaxation of adjoining structure flatness requirements.

Finite element models (FEMs) nominally assume perfect flatness of adjoining structures. Therefore, FEMs can obscure this potentially significant

reduction in structural margin.

Figure 4-12: FEM simulates a clamp band separation system via radially inward preload from band tension. Warping can result

2003336C Advanced Lightband User's Manual PSC by Rocket Lab

February 2023 https://www.rocketlabusa.com/space-systems/separation-systems/ Page 19 of 41

Figure 4-13: A deflection of 0.004 inches at the interface to adjoining structures is created by preload

ALBs and clamp bands embody the challenging nature of mechanical assembly; not only do they warp in proportion to preload, but a warp applied to

them can affect their preload. Critically, as many mechanisms engineers have observed in test, the structural performance (strength and stiffness) is

highly correlated to preload. PSC-RL engineers often observe changes in internal strain as structures are joined to the ALB. A 20% change in

preload as the separation system is fastened to an adjoining structure has been observed.

Easily fabricated structures adjoining separation systems may be expensive to make flat. Alternatively, structures that may be expensive to fabricate

can be easy to make flat. For example, a thrust cone that interfaces the final stage engine to the launch vehicle can be easily made by riveting

machined rings to conical sheets. The riveting process can stress the thrust cone. This may manifest itself as warping (a lack of flatness) when the

riveted structure is removed from its much more rigid tooling. To attain flatness requirements, the riveted structure must be machined or shimmed at

additional cost. As a more expensive option, the thrust cone could be directly machined from a conical forging ensuring flatness requirements are

met.

Engineers should consider the fact that all manufacturing and joining processes (riveting for assembly, fastening to adjoining structures, curing of

composites) increase strain energy and thus will warp structures.

2003336C Advanced Lightband User's Manual PSC by Rocket Lab

February 2023 https://www.rocketlabusa.com/space-systems/separation-systems/ Page 20 of 41

4.12 SoftRide and ALB

The SoftRide Isolation System is a spacecraft vibration and shock isolation system designed to reduce launch vehicle-induced loading on the

spacecraft. SoftRide is a patented product of Moog CSA Engineering (www.csaengineering.com). It has been flown successfully many times.

Bicycle

Car

Aircraft

Spacecraft

Table 4-5: Valuable payloads are isolated from detrimental external loading using spring-damper (isolation) systems

SoftRide Systems have several benefits when used in conjunction with the ALB:

1. Substantially reduce flight loads into the payload such as engine transients, random vibration, and shock.

2. Substantially reduce risk by isolating the payload from unanticipated launch load events.

3. Substantially increase damping. SoftRide damping ratio range is 3% to 25% depending on the needs of the mission.

4. Reduce stiffness requirements of the space vehicle because there is less value to a very stiff bus if it is sitting on a very flexible isolation

system.

5. Reduce flatness requirements of adjoining vehicles because the isolation system is flexible.

6. Ease integration of the ALB by eliminating the need to stow the ALB to join the satellite to the launch vehicle. With the isolation system

attached to the already stowed ALB, integration can occur by simply fastening the launch vehicle to the isolation system.

Figure 4-14: Moog CSA’s SoftRide OmniFlex which isolates the satellite from the launch vehicle loads

Isolation systems add mass that is usually small compared to the spacecraft mass. In fact, the mass added by SoftRide is often nullified because the

ALB has a lower mass than other separation systems. Isolation systems require a displacement stroke to attenuate dynamic loads.

4.13 Lifecycle

An ALB cycle is defined as one stow and one separation. Refer to Table 3-1 for max number of cycles (Noted as Life, Deployments). If cycles equal

or exceed the allowable, the unit must be returned to PSC-RL for inspection and possible refurbishment. Contact PSC-RL for pricing and schedule.

2003336C Advanced Lightband User's Manual PSC by Rocket Lab

February 2023 https://www.rocketlabusa.com/space-systems/separation-systems/ Page 21 of 41

4.14 Rotation Rates

Rotation rates are induced by the distance between the payload’s center of mass (CM) and the center of the ALB’s spring force. Rotation rates may

be about any axis of a space vehicle as a result of the separation event.

Rotation rates can be estimated via Equation (3). There are many variables that contribute to this rate and several simplifying assumptions have

been made to compensate. Equation (3) assumes the adjoining vehicle is many times more massive (>10X) and has many times more inertia (>10x)

than the separating vehicle. It also assumes the pre-separation rates are all zero. Only Separation Reliability testing can produce verifiable values

for rotation rates.

Figure 4-15: CM offset and rotation rate

w =

mvd

I

(3)

Where:

w is the payload rotation rate [rad/s]

m is the mass of the payload [mass]

v is the relative velocity [length/s]

d is the distance between the CM and the resultant location of the Separation Springs [length]

I is the mass moment of inertia about the center of mass of the separating vehicle [mass∙length

2

]

Figure 4-16: An illustration of Equation 4

The Separation Spring configuration may be adjusted on the ALB so the Springs, as a sum, act through the CM. Table 3-1 provides all the

information to complete dynamic analysis of the separation event. Though typically trivial, even the effect of the spring in the Separation Switches

and Separation Connectors may be incorporated into dynamic models.

Modern CAD models of spacecraft inform designers of the CM location allowing them to control it to within thousandths of an inch prior to

manufacture. Testing has confidently shown that when d = 0.0±.01 in the expected tip-off will be within 2 degrees per second.

Rotation rates can be beneficial. It tends to average out the temperatures on the spacecraft, and if a camera attached to the launch service is

looking at the spacecraft while it is rotating after separation, mission managers can verify configuration in spaceflight. For example, are the stowed

solar arrays intact?

m = 181 kg

v = 0.5 m/s

I = 12 kg*m

2

2003336C Advanced Lightband User's Manual PSC by Rocket Lab

February 2023 https://www.rocketlabusa.com/space-systems/separation-systems/ Page 22 of 41

4.15 Separation Velocity and Separation Springs

Equation (4) is used to calculate the required total separating energy, E, given a desired velocity between the payload and final stage.

E =

(

mM

)

v

2

(

m + M

)

(4)

Equation (5) is used to calculate the estimated number of Separation Springs, S, required given a desired velocity between the payload and the final

stage.

S =

mM

m + M

×

v

2e

(5)

Equation (6) is used to calculate relative velocity, v, between payload and final stage given a known total stored energy.

v =

2E

(

m + M

)

mM

(6)

Where:

m is the payload mass [kg] (includes mass of ALB Upper Ring)

M is the final stage mass [kg] (includes mass of ALB Lower Ring, excludes payload mass)

v is the relative velocity between m and M [m/s] (ΔV or separating velocity)

S is the number of Separation Springs [-] (even qty. preferred)

e = 2.45 J is the stored potential energy of a single Separation Spring that is converted to kinetic energy manifested as v. It includes efficiency losses.

E = S∙e is the total ALB separating energy manifested as v [J] (The stored potential energy of all Separation Springs that is converted to kinetic

energy. It includes efficiency losses. See Table 3-1 for typical ranges for each ALB size.)

Example 1: velocity is known, total separating energy is desired

Payload mass, m = 200 kg

Final stage mass, M = 3000 kg

Desired relative velocity, v = 0.356 m/s

Total Separating Energy, =

(

200 kg × 3000 kg

)

× (0.356

m

)

2 ×

(

200 kg + 3000 kg

)

= 11.9 J

Example 2: total separating energy is known, required number of Separation Springs is desired

Total separating energy, E =11.9 J

Number of Separation Springs, =

11.9

2.45

= 4.86

Example 3: Total separating energy is known, relative velocity is desired

Payload mass, m = 200 kg

Final stage mass, M = 3000 kg

Total separating energy, E =12.25 J

Relative velocity, =

2 × 12.25 J ×

200 kg + 3000 kg

200 kg 3000 kg

= 0.361

m

s

Observe that the quantity and mass of Separation Springs increases with the square of v. A small increase in velocity requires a significant increase

in Springs. The allowable quantity of Separation Springs varies by ALB diameter.

Figure 4-17: The relative velocity (v) is created by the Separation Springs (S)

2003336C Advanced Lightband User's Manual PSC by Rocket Lab

February 2023 https://www.rocketlabusa.com/space-systems/separation-systems/ Page 23 of 41

Figure 4-18: Spring quantity required increases with the square of velocity (springs are lousy rocket engines)

The location of Separation Springs, Separation Connectors, and Separation Switches need not be symmetric to minimize rotation rates. Sometimes

PSC-RL engineers will modify the location (configuration) of Separation Springs to null out rotation rate torques during Separation Reliability tests

(this is a custom test).

When several payloads are on the same launch vehicle, engineers can minimize the possibility of re-contact by varying the separation velocity and

direction. Angling the payloads so they push through the center of mass reduces rotation rate torques and the possibility of re-contact.

The ALB will work without any Separation Springs—it just won’t have any velocity. However, if Separation Connectors or Separation Switches are

installed, the ALB will separate with a very small separating velocity due to the small force of the spring plungers.

Figure 4-19: Spacecraft oriented so they reduce the moment arms between center of force and center of mass

2003336C Advanced Lightband User's Manual PSC by Rocket Lab

February 2023 https://www.rocketlabusa.com/space-systems/separation-systems/ Page 24 of 41

5. Vertical and Horizontal Integration to Adjoining Vehicles

Figure 5-1: Typical vertical and horizontal integration methods

The compliance of the entire stack needs to be assessed to properly integrate the ALB. When the ALB is stowed as part of the integration process,

the entire system will be structurally indeterminate. If the space vehicle and Upper Ring are too far from the Lower Ring or improperly aligned, the

ALB will have to pull the space vehicle down and vice versa. To minimize this effect, a compliance spring and/or a more precise control of space

vehicle position in all six degrees of freedom is necessary.

2003336C Advanced Lightband User's Manual PSC by Rocket Lab

February 2023 https://www.rocketlabusa.com/space-systems/separation-systems/ Page 25 of 41

Figure 5-2: Horizontal and vertical integration

Flatness of the adjoining surfaces should be within the flatness requirement. See Table 3-1. If flatness requirements are not met by the structure,

shims (epoxy or metal) can be used to attain the required flatness.

Flexible adjoining structures may distort while lifting to mate the structures. Simple static analysis can expose any detrimental distortion due to lifting

hard-points and weight.

2003336C Advanced Lightband User's Manual PSC by Rocket Lab

February 2023 https://www.rocketlabusa.com/space-systems/separation-systems/ Page 26 of 41

6. Reliability, Failure Modes and Anomaly Reporting

ALB reliability will be maximized by strictly adhering to the procedures in this document. Over a thousand separation tests on more than 20 ALBs

before, during, and after critical development and qualification tests (thermal-vacuum, shock, vibration, strength, separation reliability, etc.) over

several years show reliability and confidence.

6.1 Failure Modes, Effects and Preventative Actions

Failure Mode

Effect(s)

Preventative Action

Operator fails to remove Stow Screw prior to

initiation

Failure to separate

Follow procedures

Operator fails to remove Spring Locks prior to

initiation

Lower separation velocity and/or higher

rotation rates

Follow procedures

Initiator voltage or current is too high or too low;

too short or too long

Failure to initiate or damage to initiator

Follow procedures

Subsystems loosen (Switch, Connector, Spring)

Decreased performance, debris

Verify and record torque at all

fasteners joining subsystems

Cross-threading screw

Screw is seized, proper assembly is

prevented

Verify all screws and their

accepting threads are within

specification and free running

Flatness of interfacing boundaries are out of

tolerance.

System will not stow or will be difficult to

stow.

Inspect boundary interfaces

FOD in DE-9 connector

Increased electrical resistance

Inspect and clean pins and

sockets prior to mate

Operator fails to follow stow procedure, exceeds

max torque or max turns

ALB detrimentally damaged, requires PSC-

RL rework

Procedures, checklists, PSC-RL

provided training

Loopbacks in Separation connector are too long

to allow proper seating of Matrix

Pins are damaged

Verify Matrix seats properly

before integration to ALB

Stow screw torque is exceeded or operator turns

past ‘Ping’

ALB won’t deploy

Adhere to operating procedures,

checklists and training

Table6-1: Failure Modes, Effects and Preventative Actions

2003336C Advanced Lightband User's Manual PSC by Rocket Lab

February 2023 https://www.rocketlabusa.com/space-systems/separation-systems/ Page 27 of 41

7. Testing

PSC-RL completes acceptance testing on standard flight ALBs prior to delivery. EDU ALBs only receive build verification tests. PSC-RL’s testing of

the ALB does not include the customer’s wiring harness. Typically, Transition Rings are fastened to the ALB during testing to mimic flight-like

structural, thermal, and dynamic boundary conditions. There is no fixed sequence for acceptance tests. PSC-RL writes, executes, and approves all

test plans. PSC-RL also takes any corrective action if anomalies arise. PSC-RL may employ a lot testing strategy, at PSC-RL discretion (i.e. all units

within one lot may not receive all testing).

Special (Custom) testing is not included and adds cost and schedule.

Test

Standard or

Special?

Build Verification (pre-BCR)

Standard

Random Vibration Test

Standard

Thermal Vacuum Test

Standard

Separation Reliability Test

Special (Custom)

Strength Test

Special (Custom)

Shock Test

Special (Custom)

Table 7-1: Standard vs Custom test summary

7.1 Test Summary

These values may be exceeded at PSC-RL’s discretion.

Test

Parameter

Qualification

Protoflight

Flight (Acceptance)

EDU

Build

Verification

Preload Tuning [-]

proprietary

proprietary

proprietary

proprietary

Benchtop Operations [-]

≥7

≥7

≥7

≥7

Random

Vibration

Level [grms], ± 1 dB

14.1

14.1

10.0

Not Performed

Duration [s/axis], +10%/-0%

180

60

60

TVAC

Temp [°C], ±3.0 °C

-50 to 110

-29 to 66

-24 to 61

Not Performed

Cycles, min [-]

10

8

4

Separations [-]

6

2

1

Shock

Levels

See Figure 7-4

See Figure 7-4

Not Performed Not Performed

Impacts/axis

3

2

Strategy

positive & negative

maxi max

Separation

Separations, min [-]

100

5

Not Performed

Not Performed

Strength

Axial Line Load [lbf/bolt]

2064

Not Performed Not Performed Not Performed

Shear Line Load [lbf/bolt]

775

Fatigue

Axial Line Load [lbf/bolt]

See Figure 7-7

Not Performed Not Performed Not Performed

Cycles

See Figure 7-7

Table 7-2: Test Summary

7.2 Build Verification

The ALB is tuned to achieve optimal retention and separation characteristics. Throughout build the ALB is stowed and deployed to verify nominal

operation. The Springs elongate, and the Separation Switches and Separation Connectors change state. Transition Rings are fastened to the ALB to

produce flight like structural boundary conditions. These verifications are completed during the build process prior to Build Complete Review (BCR)

and do not have stand-alone test procedures.

Figure 7-1: Benchtop Separation Testing

Qualification Proto-Flight Acceptance (Flight) EDU

Benchtop Separations Separations [-] >100 ≥7 ≥7 ≥7

Te st

Parameter

Use

2003336C Advanced Lightband User's Manual PSC by Rocket Lab

February 2023 https://www.rocketlabusa.com/space-systems/separation-systems/ Page 28 of 41

7.3 Component Random Vibration

The ALB is exposed to random vibration in three orthogonal excitation axes to verify workmanship and demonstrate a capability to survive transport

or flight vibration.

Figure 7-2: Random Vibration Testing

7.4 Thermal Vacuum

The ALB is exposed to temperatures and pressures of spaceflight. ALB is initiated and separated in a vacuum at a temperature extreme and

initiation voltage extreme.

Figure 7-3: TVAC Testing

Qualification Proto-Flight Acceptance (Flight) EDU

Level [g

rms

] 10±1dB

Duration [s/axis] 180+18/-0 60+6/-0 60+6/-0

Excitation Axes [-]

Component Random Vibration

14.1±1dB

Not Performed

X, Y, Z

Te st

Parameter

Use

0.010

0.100

1.000

10 100 1000

ASD [g

2

/Hz]

Frequency [Hz]

Qual/Proto

Acceptance

Qualification Proto-Flight Acceptance (Flight) EDU

Temperature (

±3) [°C] -50 to +110

-29 to +66 -24 to +61

Pressure [Torr]

Cycles [-]

≥10 ≥8 ≥4

Separations [-] ≥6

2 1

Te st

Parameter

Use

Thermal Vacuum

Not Performed

<1.0E-4

2003336C Advanced Lightband User's Manual PSC by Rocket Lab

February 2023 https://www.rocketlabusa.com/space-systems/separation-systems/ Page 29 of 41

7.5 Shock (Custom Test)

The ALB is exposed to simulated flight shock.

Figure 7-4: Shock Testing

7.6 Separation Testing (Custom Test)

The ALB is separated repeatedly to monitor nominal operation. This may be performed as a benchtop test or on the PSC-RL Separation Reliability

fixture, a 5 degree of freedom air bearing table. During Separation Reliability, tip-off rates and separation energy are measured and recorded.

Figure 7-5: Separation Reliability Testing

Qualification Proto-Flight Acceptance (Flight) EDU

Shock Level [g] Not Performed

Not Performed

See following figure

Te st

Parameter

Use

1

10

100

1,000

10,000

100 1,000 10,000

Acceleration [g]

Frequency [Hz]

Qual

Protoflight

Qualification Proto-Flight Acceptance (Flight) EDU

Separation Testing Operations [-] 100 5 Not Performed Not Performed

Te st

Parameter

Use

2003336C Advanced Lightband User's Manual PSC by Rocket Lab

February 2023 https://www.rocketlabusa.com/space-systems/separation-systems/ Page 30 of 41

7.7 Strength (Custom Test)

The ALB is exposed to line loading at the specified limits. Reactions in the ALB may be produced with sine-burst testing or with hydraulic rams. Sine-

burst testing requires a PSC-RL supplied mass simulator.

Figure 7-6: Strength Testing

7.8 Fatigue (Custom Test)

The ALB is cyclically loaded. Reaction forces are excited through dynamic loads, reaching a prescribed line load to a required number of cycles. A

PSC-RL supplied mass simulator is required.

Figure 7-7: Fatigue Testing

Qualification

Proto-Flight Acceptance (Flight)

EDU

Axial Line Load (Peq)

[lbf/bolt]

2064

Shear line load (Q)

[Lbf]

775

Parameter

Use

Te st

Strength (sine burst or static)

Not Performed

Not Performed

Not Performed

Qualification Proto-Flight Acceptance (Flight) EDU

Axial Line Load [lbf/bolt]

1188 | 893 | 670

Cycles [-]

100 | 800 | 10000

Fatigue (sine burst or sine dwell)

Not Performed

Not Performed

Not Performed

Te st

Parameter

Use

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

2.00

[s]

-12

-10

-8

-6

-4

-2

0

2

4

6

8

10

[g]

Chan. no: 22

Chan. type: M

Level: 0.0 dB

Resolution: 2.44e-004

Unit: g

Peak (curr.): 10.17 g

Peak (ref.): 9.87 g

-- Pulses on curr. level

done: 1

remaining: 9

-- Pulses total --

done: 14

remaining: 15

Date: 02-19-20

Time: 13:57:07

Product version:

VTL-20-018

Y-axis, Run #002

Operator: Luke Boggs

Program: PSC

Test Engr: Chris Flood

Item: ALB-8

Y-axis Qual Sine Burst,

Budget: EEP22XXX

R6Y, Stack CM +Z

Shock SRS

Test Engr: Chris Flood

Item: ALB-8

Y-axis Qual Sine Burst, ALB-8 Load Case #001

2003336C Advanced Lightband User's Manual PSC by Rocket Lab

February 2023 https://www.rocketlabusa.com/space-systems/separation-systems/ Page 31 of 41

8. Specifying an ALB

8.1 Determine stiffness requirements

The biggest driver in ALB diameter selection should be payload stiffness requirements. From dynamic envelope mission requirements, determine

the required axial and lateral stiffness of the payload stack. The minimum ALB diameter can then be selected from Table 3-1. However, it is prudent

to choose an ALB diameter larger than necessary to provide additional stiffness margin at less than an equivalent increase in weight. For example, a

15-inch diameter ALB is about 6.6 times stiffer than an 8-inch diameter ALB but weighs less than twice as much.

8.2 Determine strength requirements

From your expected mission loads on the payload, calculate maximum line load. Verify that mission loads required to attain those line loads are less

than maximum ALB loads shown in Table 3-1. If not, increase the chosen ALB diameter until allowable line load is achieved. PSC-RL will request

mass of payload, center of mass location (in ALB coordinate system), and quasistatic load factors at Kick-off to verify adherence to strength

requirements.

8.3 Select ALB Bolt Circle diameter

Choose an appropriate ALB diameter from Table 3-1 based on stiffness and strength.

8.4 Complete virtual fit check and plan logistics

Integrate both the ALB stay-out zone model and a CAD model of the ALB (download from www.planetarysystemscorp.com or contact PSC-RL) with

a model of your payload and verify your fit requirements. Pay close attention to all stay-out zones per Table 3-1 as the CAD model may not

represent the maximum travel of all components. Remember to include your wiring harness. Also determine how you will fasten and operate the ALB

for shipment, testing and final integration procedures. Determine the electrical and mechanical ground support equipment (GSE) needed.

8.5 Separation Switch quantity (SW)

The greater the quantity of Separation Switches, the more complex and heavier the harness. See Table 3-1 to ensure the total quantity of

Separation Switches and Separation Connectors does not exceed the maximum allowable.

8.6 Separation Connector quantity (SC)

As with Separation Switches, fewer Separation Connectors allow for a simpler harness. Connectors are specified as pairs, so one Connector

consists of both the Lower and Upper halves. See Table 3-1 to ensure the total quantity of Separation Switches and Separation Connectors does

not exceed the maximum allowable.

8.7 End Use (FLT or EDU)

Engineering Development Unit (EDU) ALBs receive only a bench-top separation test. They do not receive acceptance testing and shall not be used

for flight. As such, EDUs are indelibly marked “NOT FOR FLIGHT.”

Flight Units (FLT) receive testing per Section 7 prior to shipment. If special testing is required (shock, strength, separation reliability, off-set center of

mass separation reliability, etc.) additional schedule and cost is typically incurred.

EDU and FLT ALBs are built using the same materials and processes. Customers often purchase an EDU in addition to a FLT for fit checks and

ground testing.

8.8 Separation Springs

Use Equation (5) to specify the number of Separation Springs that creates the desired separating velocity or separating energy. A standard ALB

comes with 3 Separation Springs (~7.4 J) or 4 Separation Springs (~9.8 J) depending on the diameter of the Lightband (refer to Table 3-1).

Additional Separation Springs can be purchased for customer installation. More than n/4 or less than the standard quantity of Separation Springs is

a custom unit.

8.9 Specifying ALB

Use the following convention to specify the ALB: ALBXX-SW-SC-FLT-XX

Required

Prefix

Bolt Circle

Diameter

(rounded down)

Separation

Switch

Qty.

Separation

Connector

Qty. [pairs]

End Use

(Flight or

EDU)

Separation

Springs [-]

ALB

XX

SW

SC

FLT

XX

Table 8-1: ALB specification convention

For example, ALB11-1-2-FLT-3 specifies

• ALB – Advanced Lightband

• 11 – 11.732-inch bolt circle diameter

• 1 – Separation Switch

• 2 – Separation Connector pairs (2 Lower and 2 Upper)

• FLT – Be used for space flight and thus receive testing

• 3 – Separation Springs, separating kinetic energy of ~7.4 J

2003336C Advanced Lightband User's Manual PSC by Rocket Lab

February 2023 https://www.rocketlabusa.com/space-systems/separation-systems/ Page 32 of 41

9. Purchasing, Deliverables, & Schedule

9.1 Purchasing an ALB

Contact PSC-RL directly to receive the most up-to-date ALB prices. The standard payment schedule is shown below.

Event

Payment [%]

After Kick-off Meeting

35

Build complete review (BCR) completion

45

Shipment

20

Table 9-1: Standard ALB schedule

9.2 Standard Delivery Schedule

Standard ALBs are typically delivered in 30 weeks ARO. Expedited delivery is available at an additional cost. Custom or Special testing (e.g., shock,

strength, separation reliability, CM off-set separation reliability, etc.) increases schedule and cost.

9.3 ALB Deliverables

The items included in the price of an ALB and delivered to the customer are:

1. The ALB(s)

2. Certificate(s) of conformance

9.4 ALB STEP Files

STEP files of simplified ALB assemblies are available to prospective users and customers. Users may request a STEP model at

www.planetarysystemscorp.com

.

Note: ALB STEP models do not show all components or their full extent of travel. Users shall not use simplified ALB STEP models to verify

clearance. Instead use the stay-out zone CAD models for clearance verification.

9.5 ALB Finite Element Models

PSC-RL has test-verified finite element models (FEM) of ALBs available for customers. To accurately predict line loading through the ALB,

customers should incorporate the FEM into their flight stack model. Contact PSC-RL for further information. FEMs may incur an additional cost. This

item is subject to US Export Control regulation.

9.6 Custom Units

ALB is a COTS separation system. Any customization (e.g., testing, configuration, program management, additional customer requirements,

accelerated schedule, etc.) will incur additional cost and schedule. Figure 9-1 has a summary checklist to compare standard vs custom ALBs, the

custom list is not all-encompassing (there may be additional unlisted items which necessitate a custom unit).

Figure 9-1: Standard vs. Custom Lightband

9.7 Accessories

Separation Switches, Separation Connectors, and Separation Springs, may be delivered earlier than the ALB. Accessories delivered not attached to

a flight ALB will not receive testing. PSC-RL does not install spare accessories for testing as a standard service. Accessories may be installed at any

step through build and test. Separation Connectors and Separation Switches may not receive the full suite of testing. All Accessories should be

listed as individual line items on the PO/contract. All PSC-RL paperwork will list parts as individual line items.

9.7.1 Separation Connectors

Separation Connectors are sold in pairs (an -Upper and -Lower half). Each half will be listed as an individual line item.

• 4000932-Upper, ALB Separation Connector Assembly Upper

• 4000932-Lower, ALB Separation Connector Assembly Lower

Note: Quantity 2 (per half, 4 per pair), NAS1352N06-7, .138-32 x .438 SHC Screws, are required to attach the ALB Separation Connector to the ALB

Upper/Lower Ring. PSC-RL does not sell fasteners and does not include loose fasteners when accessories are not attached to the ALB.

2003336C Advanced Lightband User's Manual PSC by Rocket Lab

February 2023 https://www.rocketlabusa.com/space-systems/separation-systems/ Page 33 of 41

9.7.2 Separation Switches

Two parts are typically ordered for each Separation Switch (if procuring flight spares, only the Switch needs to be procured):

• 4000952 Separation Switch (includes a .375-32 x .625 x .094 thin hex nut) - this is the actual switch.

• 4000922 ALB Switch Bracket – this bracket is required to attach the switch to the ALB.

Note: Quantity 2, NAS1352N06-7, .138-32 x .438 SHC Screws, are required to attach the ALB Switch Bracket to the ALB Upper/Lower Ring. PSC-

RL does not sell fasteners and does not include loose fasteners when accessories are not attached to the ALB.

9.7.3 Separation Springs

Three parts make up a single Separation Spring

• 4000920 ALB Spring Stop

• 4000921 ALB Spring Guide

• Separation Spring, 1.06 x .79 x 53.2 Compression Spring

Note: Quantity 1, NAS1352N3-10, .190-32 x .625 SHC Screw, is required to attach spring parts to an ALB Lower Ring. PSC-RL does not sell

fasteners and does not include loose fasteners when accessories are not attached to the ALB.

To stow the Spring an ALB Spring Lock is required. See Section 12.

10. Manufacturing Process

Employees at PSC-RL design, assemble, and test separation systems. PSC-RL is an AS 9100-compliant organization. All of the machining and

fabrication is completed by vendors qualified to PSC-RL’s standards. PSC-RL maintains documentation of all tasks associated with flight hardware

procurement, inspection, storage, assembly, test, and shipment. All of these are enveloped by PSC-RL’s quality management program. Procuring,

manufacturing, and stocking are controlled by inventory management software. ALBs and their subsystems are tracked and completely traceable

using their purchase order, serial number, or lot number. Just like in testing at PSC-RL, manufacturing is done in teams. Two employees typically

sign-off on steps in manufacturing procedures (one acts as the technician, the other as quality assurance) and execute a Build Complete Review

(BCR) as the final step in the completion of the manufacturing procedures. PSC-RL writes, executes and approves manufacturing procedures. PSC-

RL also takes any corrective action if anomalies arise. The customer-furnished wiring harness is not included in the manufacturing of an ALB.

11. ALB Testing and Procedures Performed by Customer

Customers often complete some of these tests and procedures after receiving the ALB.

Test or procedure

Objective

Remarks and cautions

ALB training

Learn how to operate ALB and uncover

unexpected potential integration difficulties

Verify operators are trained to operate the

ALB

Fit check to adjoining structures Verify bolt patterns and clocking

Is the electrical wiring harness attached

during this procedure?

System-level vibration test Verify workmanship and modes

Will the ALB be overloaded at resonance? Are

notching or force limiting methods employed?

EDU ALBs are great for this test.

Electrical initiation test

Verify the initiation circuit and power system

from the launch vehicle will initiate the ALB

within specification. Verify adjoining vehicles

will receive the proper signal upon separation.

Ensure ALB operation procedures are being

followed.

Table 111-1: Testing and other procedures

Figure 111-1: Electro-mechanical fit check and a separation test

2003336C Advanced Lightband User's Manual PSC by Rocket Lab

February 2023 https://www.rocketlabusa.com/space-systems/separation-systems/ Page 34 of 41

12. Ground Support Equipment (GSE)

For program planning, several pieces of GSE are listed below that have been useful to customers in the past.

Item

Description

Graphic

Transition Ring

NOT SUPPLIED

NOR SOLD BY

PSC-RL

Fastens to the Upper or Lower Ring.

Useful to attenuate flatness issues of

adjoining structures, allow access to

fasteners, simulate stiffness of adjoining

structure

Vibration Adapter

Plate

NOT SUPPLIED

NOR SOLD BY

PSC-RL

The interface between an electro-dynamic

exciter and the ALB or a Transition Ring.

Oscilloscope,

probes, power

supply, 1.0Ω (10W)

and 8.0 Ω (150W)

resistors, 2x DE-9

breakout cables and

various banana jack

cables

NOT SUPPLIED

NOR SOLD BY

PSC-RL

Used to deploy, initiate, and

record V and I

Stow Screw

ONE SUPPLIED

WITH EACH ALB

Used to Stow ALB

Spring Lock

ONE SUPPLIED

WITH EACH

SPRING