1 Overview ............................................................................................................................... 1

1.1 History of SOS Inventory ................................................................................... 1

1.2 Workflow ........................................................................................................ 2

1.2.1 QuickBooks Online to SOS ...................................................................... 3

1.2.2 SOS to QuickBooks Online....................................................................... 3

1.3 Comparison of Pricing Plans .............................................................................. 3

1.4 QuickBooks Online Integration ......................................................................... 4

2 What’s New: User Guide Notes .......................................................................................... 5

3 Starting SOS Inventory ........................................................................................................ 9

3.1 Connection to QuickBooks Online ..................................................................... 9

3.1.1 Considerations Before Connecting ......................................................... 9

Converting from QuickBooks Desktop, Premier, or Enterprise to

QuickBooks Online ................................................................. 10

3.1.2 Creating the Connection ....................................................................... 10

3.1.3 First Sync ............................................................................................ 11

3.1.4 Sync Menu .......................................................................................... 12

3.2 Inventory Tracking in QuickBooks Online ......................................................... 12

3.3 Signing In/Out ................................................................................................ 13

3.4 Graphic User Interface (GUI) ............................................................................ 14

3.5 Navigation ..................................................................................................... 16

3.5.1 Lists ................................................................................................... 16

Display Message ..................................................................... 16

Page Navigation ...................................................................... 17

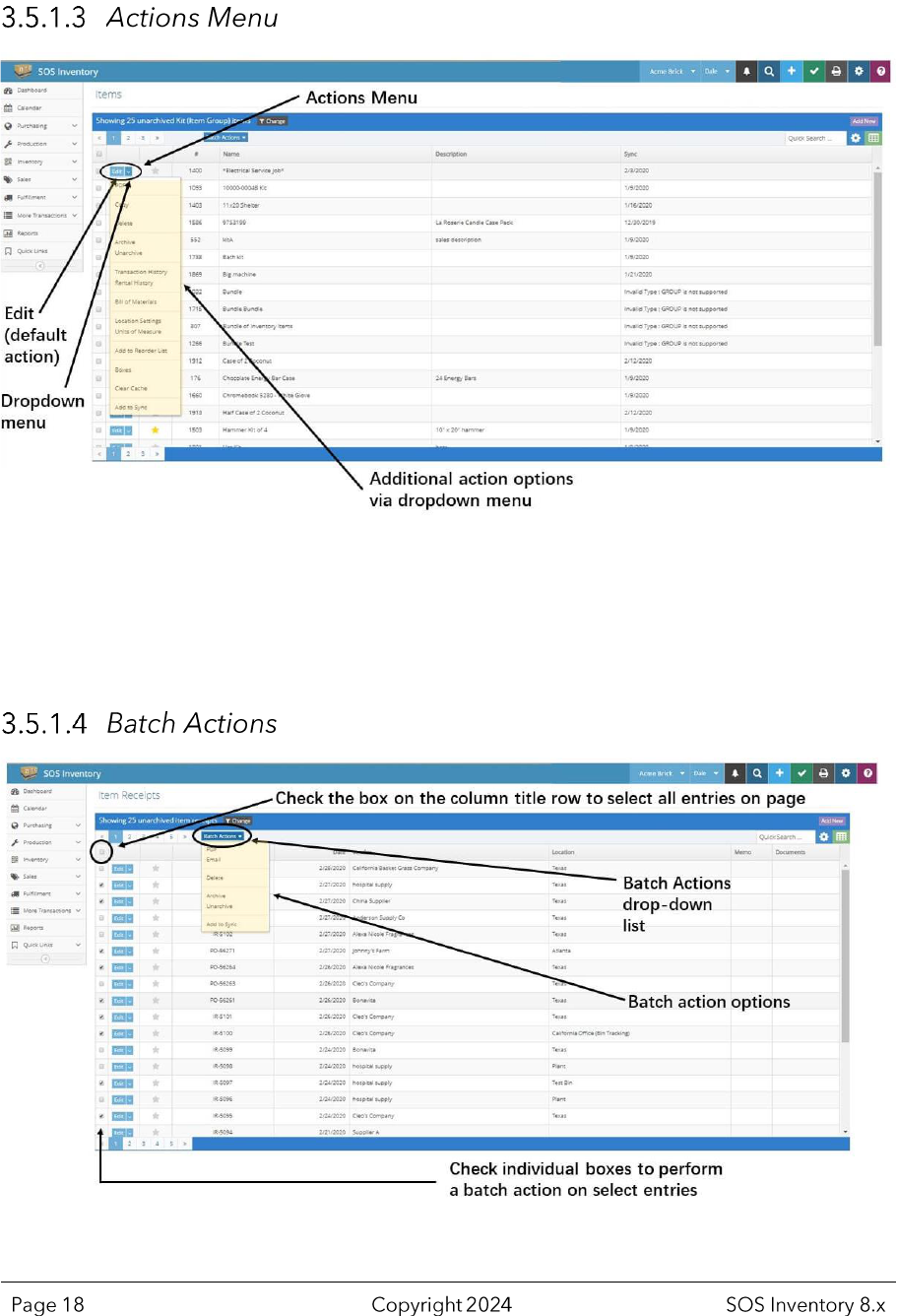

Actions Menu ......................................................................... 18

Batch Actions ......................................................................... 18

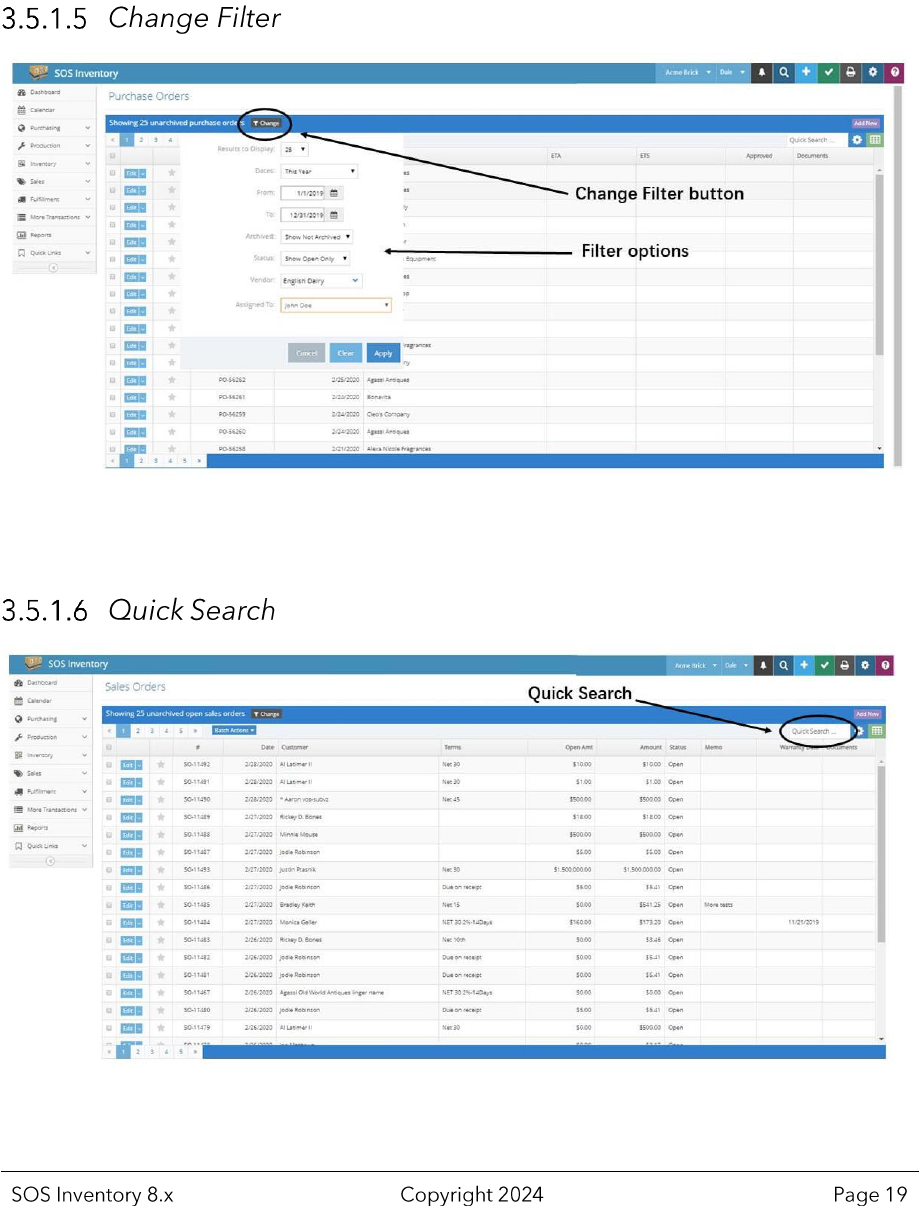

Change Filter .......................................................................... 19

Quick Search .......................................................................... 19

Add New ............................................................................... 20

Column Chooser .................................................................... 20

Excel Export ........................................................................... 22

Stars ...................................................................................... 22

3.5.2 Edit Pages ........................................................................................... 23

3.6 User Information ............................................................................................ 23

3.6.1 User Profile ......................................................................................... 23

3.6.2 User Settings ....................................................................................... 23

3.6.3 Tasks ..................................................................................................24

3.7 Switching Between SOS and QuickBooks Online .................................................24

3.8 Switching Between SOS Company Accounts ...................................................... 25

3.9 Smart Search .................................................................................................. 25

3.10 Getting Help ................................................................................................... 25

3.11 Printing ......................................................................................................... 27

4 Set Up/Configuration ......................................................................................................... 28

4.1 Company Settings ........................................................................................... 28

4.2 System Settings (Purchasing/Inventory/ Sales) .................................................. 30

4.2.1 Purchasing Settings ............................................................................. 30

4.2.2 Inventory Settings ............................................................................... 33

4.2.3 Sales Settings ...................................................................................... 37

General .................................................................................. 37

Sales Orders ........................................................................... 39

Estimates .............................................................................. 40

Invoices ................................................................................ 40

Sales Receipts ......................................................................... 41

Shipments ............................................................................. 41

RMAs ..................................................................................... 42

Returns .................................................................................. 43

Pick Tickets ............................................................................ 43

Rentals .................................................................................. 44

Rental Returns ....................................................................... 44

4.3 Barcode Settings ............................................................................................ 44

4.4 QuickBooks Setup ........................................................................................... 45

4.5 Default Accounts ........................................................................................... 46

5 Inventory .............................................................................................................................. 48

5.1 Items ............................................................................................................ 48

5.1.1 Setting Up an Item .............................................................................. 48

Item Field Descriptions ........................................................... 48

Accounts Needed According to Item Type .................................. 54

5.1.2 Items List ............................................................................................ 55

Add New ................................................................................ 55

Quick Search for Items ............................................................ 55

Filters for Items ...................................................................... 56

Actions and Batch Actions Available for Items ........................... 56

Items List Column Options ...................................................... 57

5.1.3 Creating and Using Categories .............................................................. 58

5.1.4 Item Variants ...................................................................................... 58

Creating and Editing Item Variants ........................................... 58

Converting a Variant to a Stand-alone Item ............................. 60

5.1.5 Investigating Inventory and Cost Basis Errors with Transaction History ... 61

5.2 Cost Basis ....................................................................................................... 61

5.3 Adjustments to Inventory ................................................................................ 61

5.3.1 Quantity ..............................................................................................62

5.3.2 Cost ....................................................................................................62

5.3.3 Cycle Counting .................................................................................... 63

5.3.4 Physical Inventory Worksheet............................................................... 63

5.3.5 Adjustment Account ............................................................................ 63

5.3.6 Adjusting By Units of Measure .............................................................. 63

5.4 Locations ...................................................................................................... 64

5.4.1 Adding a Location ............................................................................... 64

5.5 Transfers ....................................................................................................... 64

5.5.1 Generating Inventory Transfers from the Reorder Report ........................ 65

5.6 Serial Inventory .............................................................................................. 65

5.6.1 Using Warranties with Serial Items ...................................................... 66

Creating a Warranty in SOS Inventory ....................................... 67

5.7 Lots ...............................................................................................................67

5.8 Consignment Inventory .................................................................................. 69

5.8.1 Account and Item Setup for Consignees ................................................ 69

5.8.2 Consignment Location Setup for Consignor .......................................... 69

5.9 Barcoding ...................................................................................................... 70

5.9.1 Entering Barcode Data ......................................................................... 70

5.9.2 Printing Barcode Labels ....................................................................... 70

5.9.3 Scanning ............................................................................................. 71

5.10 Bins ............................................................................................................... 72

5.10.1 Assigning Different Default Bins to an Item at Multiple Locations ............ 73

5.11 Units of Measure .............................................................................................74

5.12 Kits (Item Groups) ........................................................................................... 75

5.13 Cost of Goods Sold (COGS) ...............................................................................76

5.14 Inventory Value ..............................................................................................76

5.15 Negative Inventory .........................................................................................76

5.16 Inventory Reports ...........................................................................................77

6 Purchasing ........................................................................................................................... 78

6.1 Vendors .........................................................................................................78

6.1.1 Defining the Vendor Name ...................................................................78

6.1.2 Vendor-Item Catalog .......................................................................... 79

Rules for Working with Vendor-Item Catalog Entries ................. 79

6.1.3 Vendor Messages ................................................................................ 80

6.2 Purchase Orders ............................................................................................. 80

6.2.1 Creating a Purchase Order ................................................................... 80

Purchase Order Transaction Fields .......................................... 80

6.2.2 Purchase Order Actions Menu Options ................................................... 83

6.2.3 Approvals ........................................................................................... 84

6.2.4 Shipping Methods ............................................................................... 84

6.2.5 Blanket POs ........................................................................................ 84

6.2.6 Payment Terms .................................................................................. 84

6.2.7 Drop Shipping ..................................................................................... 85

6.2.8 Purchase Order Prepayments ............................................................... 86

6.3 Item Receipts .................................................................................................87

6.3.1 Item Receipt Field Descriptions .............................................................88

Standard Item Receipt Fields (All Plans) .................................... 88

Other Costs Fields (Pro Plan Only) ........................................... 90

6.3.2 Partial Receiving ................................................................................. 90

6.3.3 Landed Costs ....................................................................................... 91

6.3.4 Generating Bills ................................................................................... 91

6.3.5 Variances ............................................................................................ 91

6.4 Purchasing and Receiving Workflow .................................................................92

6.5 Returns to Vendors ......................................................................................... 93

6.6 Reordering ..................................................................................................... 93

6.6.1 Reorder Points .................................................................................... 94

6.6.2 Automatic Reorder Points .................................................................... 94

6.6.3 Max Stock Level ................................................................................... 95

6.6.4 Reorder List ......................................................................................... 95

6.6.5 Reorder Report ................................................................................... 96

Running a Reorder Report at a Single Location for a Company with

Multiple Locations .................................................................. 97

6.6.6 Generating POs from the Reorder Report .............................................. 97

7 Sales ..................................................................................................................................... 99

7.1 Customer Management .................................................................................. 99

7.1.1 Creating and Editing Customers ........................................................... 99

7.1.2 Actions and Batch Actions Available for Customers ............................... 100

7.1.3 Defining the Customer Name .............................................................. 101

7.1.4 Sub-Customers vs Addresses for Customers with Multiple Shipping

Locations .......................................................................................... 101

Adding Sub-Customers ......................................................... 102

Using Addresses for Customers with Multiple Locations........... 102

7.1.5 Adding and Using Customer Types ...................................................... 102

7.2 Relieving Inventory ....................................................................................... 103

7.3 Using Sales Forms ......................................................................................... 103

7.4 Available for Sale .......................................................................................... 104

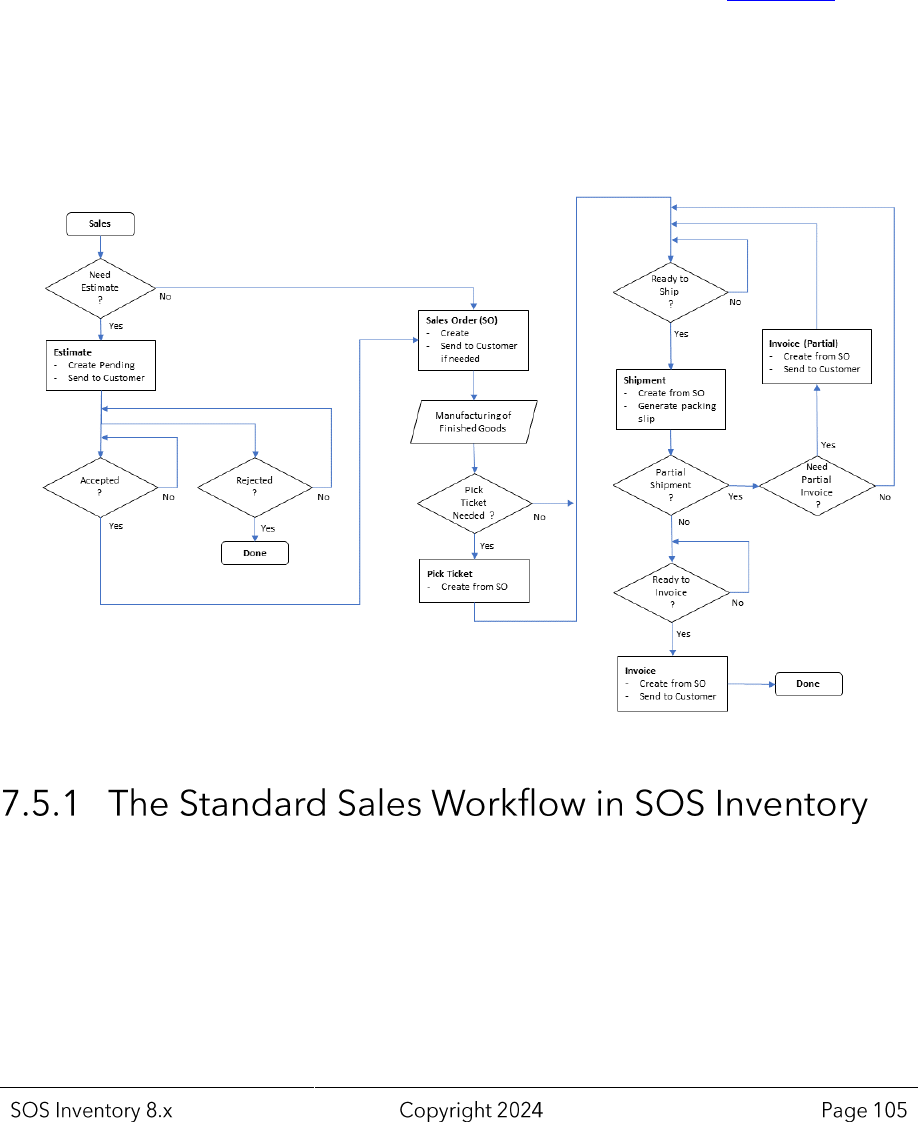

7.5 Sales Workflow ............................................................................................. 104

7.5.1 The Standard Sales Workflow in SOS Inventory ..................................... 105

7.6 Estimates ..................................................................................................... 106

7.7 Sales Orders ................................................................................................. 106

7.7.1 Sales Order (SO) Field Descriptions ...................................................... 107

7.7.2 Sales Order Actions Menu Options ....................................................... 109

7.7.3 Due Dates ........................................................................................... 111

7.7.4 Items on Sales Order ........................................................................... 111

7.7.5 Backorders ......................................................................................... 111

7.8 Invoices ........................................................................................................ 111

7.8.1 Creating Invoices ................................................................................ 112

7.8.2 Ready to Invoice Report ....................................................................... 112

7.9 Sales Receipts ................................................................................................ 112

7.10 Payments ...................................................................................................... 113

7.11 Price Tiers ..................................................................................................... 113

7.12 Sales Representatives and Sales Commissions .................................................. 114

7.12.1 Adding, Editing, and Syncing Sales Representatives ............................... 115

7.12.2 Running Sales Commission Reports ..................................................... 115

7.13 Discounts ...................................................................................................... 116

7.14 Deposits ........................................................................................................ 116

7.15 Comments .................................................................................................... 116

7.16 Terms ........................................................................................................... 116

7.17 Sales Tax ....................................................................................................... 117

7.18 Taxes for International (Non-US) Accounts ...................................................... 117

7.19 Customer Messages ........................................................................................ 117

8 Fulfillment .......................................................................................................................... 118

8.1 Pick Tickets ................................................................................................... 118

8.2 Shipments..................................................................................................... 118

8.2.1 Creating Shipments ............................................................................ 118

8.2.2 Ready to Pick/Ship .............................................................................. 119

8.2.3 Packing Slip ........................................................................................ 119

8.2.4 Automatic Shipments from QuickBooks Online Transactions ................. 119

9 Manufacturing (Production) ............................................................................................ 120

9.1 Assemblies, Builds, and the Builds List ........................................................... 120

9.1.1 Assemblies vs Processes ..................................................................... 120

9.1.2 Assemblies vs Kits (Item Groups) ......................................................... 121

9.1.3 Builds List .......................................................................................... 121

9.1.4 Building an Assembly .......................................................................... 121

Creating an Assembly Item and Its Components ...................... 122

Adding a Bill of Materials (BOM) .............................................123

Adding a Build Transaction .....................................................123

9.1.5 Using an Inventory Item as a Build Output ........................................... 124

9.1.6 Using the Expanded BOM Report in Production Planning ....................... 124

9.1.7 Using Shipments to Auto-generate Builds ........................................... 126

9.1.8 Disassembling an Assembly ................................................................ 126

9.2 Processes and Processes List .......................................................................... 127

9.2.1 Processes List .................................................................................... 127

9.2.2 Creating a Process .............................................................................. 127

Creating Process Output, Waste, and Input Items .................... 128

Creating a Process Template .................................................. 129

9.2.3 Methods for Creating a Process Transaction ......................................... 129

Add a Process Transaction Manually ....................................... 129

Add a Process Transaction with a Build's Disassemble Action ... 130

Create a Process Transaction from a Work Order .......................132

9.2.4 Waste Product and Yield Percentage .................................................... 132

9.3 Build and Process Transaction Field Descriptions ............................................. 132

9.4 Jobs ............................................................................................................. 136

9.4.1 Jobs List ............................................................................................ 136

9.4.2 Adding and Editing Jobs ...................................................................... 136

9.4.3 Job Field Descriptions ......................................................................... 137

9.4.4 Job Dashboard ................................................................................... 138

9.4.5 Job Costing (Profit/Loss) ..................................................................... 138

9.5 Work Orders ................................................................................................. 138

9.5.1 Work Orders List ................................................................................ 138

9.5.2 Adding and Editing Work Orders ......................................................... 139

9.5.3 Generating a Build or Process Transaction from a Work Order ................ 139

9.5.4 Work order field descriptions .............................................................. 140

9.6 Work In Progress (WIP) and Work Centers ....................................................... 142

9.6.1 Methods for Tracking Work in Progress (WIP) ....................................... 142

Tracking Work in Progress on the Pro Plan .............................. 142

Alternative Methods for Tracking Work in Progress (WIP) for

Companion and Plus Plan Subscribers .................................... 143

9.6.2 Work Centers .................................................................................... 144

Creating Work Centers and Assigning Stages........................... 144

Moving and Tracking a Build from One Work Center Stage to

Another ............................................................................... 145

9.7 Workers and Labor ........................................................................................ 145

9.7.1 Creating labor items .......................................................................... 146

Handling differences in labor types and rates .......................... 146

9.7.2 Enabling worker tracking ................................................................... 146

9.7.3 Adding workers ................................................................................. 146

9.8 Manufacturing Workflow ............................................................................... 147

9.9 Contract Manufacturing ................................................................................ 148

9.9.1 Contract Manufacturing Workflow ...................................................... 148

9.10 Tracking overhead costs ................................................................................. 151

10 More Transactions ............................................................................................................ 153

10.1 RMAs ............................................................................................................ 153

10.2 Returns ......................................................................................................... 153

10.2.1 Methods of Creating a Customer Return ................................................ 153

10.2.2 Customer Credit (Credit Memo) .......................................................... 154

10.2.3 Restocking ........................................................................................ 154

10.3 Rentals and Rental Returns ............................................................................. 155

11 Custom Fields ................................................................................................................... 156

11.1 Adding a Custom Field ................................................................................... 156

11.2 Custom Field Rules ........................................................................................ 157

12 Automated Order Processing (AOP) ............................................................................. 159

13 Customer Portal ................................................................................................................ 162

13.1 Customer Portal Setup ................................................................................... 163

14 Tracking Email Config ...................................................................................................... 164

15 Reports ............................................................................................................................... 166

16 Data Utilities ...................................................................................................................... 168

16.1 Updating historical costs ............................................................................... 168

16.1.1 Reconciling accounts after updating historical costs ............................. 169

16.2 Retrieving Data from QuickBooks Online ........................................................ 169

16.3 Clearing the item cache ................................................................................. 170

17 Data Export/Import .......................................................................................................... 171

17.1 Exporting Data ............................................................................................... 171

17.1.1 Data Types Available for Export ............................................................ 171

17.1.2 How to Export Data ............................................................................ 172

17.2 Editing and Importing Data ............................................................................ 173

17.2.1 Editing Guidelines ............................................................................. 173

17.2.2 Editing Items ..................................................................................... 174

Item Field Definitions for Data Export/Import ......................... 175

17.3 Importing Data ............................................................................................. 179

17.3.1 Importing Sales Orders and Sales Receipts ........................................... 180

17.3.2 Importing Bills of Materials (BOMs) .................................................... 180

17.3.3 Importing Price Tiers .......................................................................... 181

18 More on QuickBooks ....................................................................................................... 182

18.1 Syncing ........................................................................................................ 182

18.1.1 Automatic Sync ................................................................................. 182

18.1.2 Transaction Data Exchange ................................................................. 182

QuickBooks Online to SOS ..................................................... 183

SOS to QuickBooks Online ..................................................... 183

18.2 Item Type Exchange ...................................................................................... 185

18.3 Troubleshooting Sync Errors .......................................................................... 185

18.3.1 Preview Sync ..................................................................................... 186

18.3.2 Sync Errors ........................................................................................ 186

18.3.3 Sync Column on Lists ......................................................................... 186

18.4 Class Tracking .............................................................................................. 187

18.5 Department Tracking .................................................................................... 187

18.6 Other QuickBooks Online Data ....................................................................... 187

19 Third-Party Integrations and Connectors ...................................................................... 189

19.1 Standard and Billable Connections ................................................................. 189

19.2 PayPal Integration......................................................................................... 189

19.3 Shopify Integration ....................................................................................... 190

19.3.1 Item Matching .................................................................................... 191

19.3.2 Updating Inventory Levels in Shopify .................................................. 192

Updating Inventory Levels with Multiple Shopify Locations ..... 192

19.3.3 Shopify “Custom App” Cart Connection Checklist (with SKU/SKU Matching

to Support Updating Inventory Levels)................................................. 193

19.3.4 Checklist for Updating and Connecting a “Private App” in Shopify ........ 195

Updating items ..................................................................... 195

Creating a connection between SOS Inventory and a Shopify

private app ........................................................................... 196

19.3.5 Shopify Restrictions in Syncing Customer Data to SOS Inventory ........... 197

19.4 BigCommerce Integration .............................................................................. 197

19.4.1 Item Matching ................................................................................... 198

19.4.2 Updating Inventory Levels in BigCommerce ......................................... 198

19.4.3 Steps to Make Connection (with SKU/SKU Matching to Support Updating

Inventory Levels) ............................................................................... 198

19.5 FTP .............................................................................................................. 199

19.6 Cart and FTP Field Descriptions ...................................................................... 199

19.7 United Parcel Service (UPS) Integration .......................................................... 201

19.8 ShipStation Integration ................................................................................. 202

19.9 EDI Integration ............................................................................................. 202

19.10 Zapier Connector App .................................................................................... 203

20 Administration .................................................................................................................. 204

20.1 User Management ......................................................................................... 204

20.1.1 Adding Users ..................................................................................... 204

20.1.2 User Privileges ................................................................................... 204

20.1.3 Restoring Inactive Users ..................................................................... 205

20.1.4 Unlocking Users ................................................................................ 205

20.1.5 Changing the Master Administrator .................................................... 205

20.2 Account Management.................................................................................... 206

20.3 Activity Log .................................................................................................. 207

20.4 Changing Plans ............................................................................................. 207

21 Form Templates ................................................................................................................ 208

21.1 Editing a Form Template................................................................................ 208

21.2 Form Template Fields .................................................................................... 209

21.3 Using a Form Template .................................................................................. 210

22 Miscellaneous ................................................................................................................... 211

22.1 Quick Links ................................................................................................... 211

22.2 Files (Documents) .......................................................................................... 211

22.3 Alerts ........................................................................................................... 212

22.4 Notification System ...................................................................................... 214

22.5 Order Stages ................................................................................................. 215

22.6 Priorities ...................................................................................................... 215

22.7 Task List (To-Do List) .................................................................................... 215

22.8 Multi-Currency............................................................................................. 216

22.8.1 Processing Multi-Currency Transactions ............................................. 216

22.8.2 Currencies Supported by SOS .............................................................. 217

22.9 Templating ................................................................................................... 218

22.10 Channels ...................................................................................................... 219

22.11 Archive/Unarchive ........................................................................................ 219

22.12 Cash Accounting ........................................................................................... 219

22.13 Beta Features ................................................................................................ 220

22.14 Mobile Use and iOS App ................................................................................. 221

23 Steps for Successful Setup of QuickBooks Online and SOS ...................................... 222

23.1 Setup Checklist for New QuickBooks Online and SOS Accounts ......................... 222

23.2 Setup Checklist for Adding a New SOS Account to an Existing QuickBooks Online

Account........................................................................................................ 226

24 API ...................................................................................................................................... 231

25 Reconciliation Process ..................................................................................................... 232

25.1 Why Reconcile? ............................................................................................. 232

25.2 Summary of Reconciliation Process ................................................................ 232

25.3 SOS Inventory and QuickBooks Interaction ..................................................... 233

25.3.1 Purchasing Interaction ....................................................................... 233

25.3.2 Sales Interaction ................................................................................ 235

25.3.3 Adjustment Interactions .................................................................... 236

25.3.4 Assembly Build Interactions ............................................................... 240

25.3.5 Process Transaction Interaction .......................................................... 240

25.3.6 Transactions with No Effect on SOS Inventory Quantity/Value and No Effect

on QuickBooks Accounts..................................................................... 241

25.4 Reconciliation Tools ...................................................................................... 241

25.4.1 Overview ........................................................................................... 241

25.4.2 Inventory Value Report ....................................................................... 242

25.4.3 Work in Progress (WIP) Report ............................................................ 243

25.4.4 Bills (Vendor Invoice) List ................................................................... 243

25.4.5 Purchase Expense List ........................................................................ 244

25.4.6 Reconcile Item Receipts Report ........................................................... 245

25.4.7 Reconcile Vendor Credits Report ......................................................... 246

25.4.8 Reconcile Journal Entries Report ......................................................... 247

25.5 Other Factors Causing an SOS Inventory/QuickBooks Mismatch ........................ 248

25.5.1 Archived and Deleted Items ................................................................ 248

25.5.2 Transactions Deleted or Changed in QuickBooks after SOS Inventory

Created Them .................................................................................... 249

25.5.3 Unintended Journal Entries Related to Inventory Starting Value............. 249

25.5.4 Adjustments with an Incorrect Adjustment Account ............................. 249

25.5.5 Duplicate Journal Entry Posts for the Same SOS Inventory Transaction ... 250

25.5.6 Incorrect Use of “Other Cost” Items .................................................... 251

25.5.7 Transactions Added in QuickBooks that Increase/Decrease Accounts But Do

Not Affect SOS Inventory .................................................................... 251

26 Frequently Asked Questions .......................................................................................... 252

27 Glossary ............................................................................................................................. 259

28 Appendix ........................................................................................................................... 263

28.1 Report Descriptions ...................................................................................... 263

28.1.1 Accounting Reports ............................................................................ 263

28.1.2 Fulfillment Reports ............................................................................ 263

28.1.3 Inventory Reports .............................................................................. 264

28.1.4 Miscellaneous Reports ....................................................................... 265

28.1.5

Purchasing Reports ............................................................................ 265

28.1.6 Production Reports ............................................................................ 267

28.1.7 Rental Reports ................................................................................... 267

28.1.8

Sales Reports ..................................................................................... 268

This document serves as a user guide for SOS Inventory. In addition to this guide, help is also

available within the app or via the SOS Inventory website at https://www.sosinventory.com.

Please send any questions, comments, or suggestions to support@sosinventory.com.

This guide is written in a very informal, conversational style. We hope you find it more

readable and useful than your traditional, formal user manual. We update the guide frequently,

so be sure that you always grab the most recent version.

We have a section for release notes near the end of the guide for your reference as to what is

new in this manual.

SOS Inventory is the #1 inventory and manufacturing add-on for QuickBooks Online. If you are

using QuickBooks Online and do any manufacturing or anything more than basic inventory

management, you need SOS Inventory.

In April 2009, Saddle Oak Software released a new add-on product called OE Companion for

what was then called QuickBooks Online Edition. OE Companion added purchase orders,

inventory management, assemblies, document management, PayPal integration, and a few

other features to QuickBooks Online. Over time, the inventory and manufacturing features

became the most-heavily used parts of the software. In 2011, Intuit launched the Intuit App

Center and Intuit Partner Platform as a new method of connecting to QuickBooks. In July 2011,

Saddle Oak Software launched OE Companion v2, which was renamed SOS Inventory to

highlight the increased focus on inventory management and manufacturing. SOS Inventory v3

was launched in February 2012 with the move to the Intuit Anywhere platform. In March 2013,

SOS Inventory v4 was released furthering the capabilities of the platform to provide more

extensive manufacturing and inventory control. By February of 2015, SOS Inventory’s user

interface was redesigned for version 5 to more closely follow the changes that Intuit was taking

with QuickBooks Online and to make daily tasks more seamless between the environments.

In January of 2017, version 6 was released to update all pages to a newer and more enhanced

version of the edit pages for consistent processing throughout the software package. It also

added streamlined navigation, ease of use, units of measure on all transactions, custom fields,

and increased speed. SOS Inventory version 7, released in October 2017, introduced automated

order processing, added reporting capability, order staging and prioritization, in app

notification system and expanded alert system, a customer portal, and new third-party

integrations.

In the January 2019 release of version 8, SOS Inventory upgrades included a new reporting

engine and migration to a new server infrastructure.

Fullsteam, LLC, purchased SOS Inventory from Saddle Oak Software in January 2019. With that

acquisition, Fullsteam adopted our software name as the company name for the new Fullsteam

subsidiary: SOS Inventory, LLC.

This guide will showcase the features and functions that users have come to rely on, as well as

acquaint them with some new ones.

The workflow that you will use in SOS Inventory depends ultimately on your company’s

business processes. The software is flexible enough to handle a wide variety of different

scenarios. With that said, here is a general sequence that most companies will follow:

1. Order raw materials or products from vendors by creating purchase orders. (Purchasing

menu)

2. Receive the goods into inventory by creating item receipts. (Purchasing menu)

3. Turn raw materials into finished goods using builds or process transactions.

(Production menu)

4. Take sales orders from customers. (Sales menu)

5. Ship goods to customers by creating shipments. (Fulfillment menu)

6. Invoice the customer for goods shipped. (Sales Menu)

One question that we get a lot is about whether the user should use SOS Inventory or

QuickBooks Online to enter orders or other data. The answer is that either will work, and the

optimal workflow really depends on the specific needs of your company. With the automated

order processing feature, the user has even more options to make decisions on how best to

design and utilize SOS to the fullest.

For companies that are already QuickBooks Online customers, and who perhaps have users

who are very comfortable with QuickBooks Online, SOS reads transactions directly from

QuickBooks Online so that QuickBooks Online can be used as the primary place for users to

work. SOS will read new invoices, sales receipts, etc., from QuickBooks Online and generate

shipments, sales orders, reorder alerts, or other transactions automatically, as specified in the

SOS settings.

Most companies using SOS Inventory use SOS for all their day-to-day operations (purchasing,

shipping, manufacturing, etc.). In this model, information is entered into SOS and then

synchronizes to QuickBooks Online as appropriate, so that all financial data are kept up to

date. Users retrieve their inventory data and run inventory reports from SOS Inventory. The

workflow most commonly begins with a sales order as the driver of other transactions,

although this is not required.

SOS Inventory offers three different pricing plans: Companion, Plus, and Pro. A brief

description of the plans is below. A complete description and feature-by-feature comparison is

on the Pricing page of our website at https://www.sosinventory.com/pricing.

•

Companion.

The Companion plan is useful for companies who want to use QuickBooks

Online as their primary system but need just a little more functionality than

QuickBooks Online can provide. The Companion plan adds to QuickBooks Online the

capabilities of sales orders, assemblies, partial shipping/receiving, kits, and backorder

tracking, among other things. The Companion plan includes support by email only.

Email support hours are 7 a.m. – 8 p.m. Central, Monday through Friday, as well as 12-

4 p.m. on Saturday and Sunday.

•

Plus.

The Plus plan is our most popular plan. It is useful both for companies who want

to use QuickBooks Online as a primary or SOS as a primary. The Plus plan includes all

the features of the Companion plan plus price tiers, multiple warehouses, RMAs, bins,

pick tickets, barcoding, serial numbers, lot numbers, units of measure, and rental

inventory, among other things. The Plus plan includes email and phone support. Email

support hours are 7 a.m. – 8 p.m. Central, Monday through Friday, as well as 12-4 p.m.

on Saturday and Sunday. The SOS Support team is available by phone from 9 a.m. – 6

p.m. Central, Monday through Friday.

•

Pro.

The Pro plan is our most sophisticated plan. It is most often useful for companies

needing advanced inventory and manufacturing metrics, as well as companies using

SOS Inventory for all their day-to-day operations. In addition to all the features of the

Plus plan, the Pro plan supports landed costs, work orders, job costing, multiple work

centers, work-in-progress (WIP), labor, overhead, basic MRP functionality, and a

customer portal, among other things. The Pro plan includes email and

priority

phone

support. Email support hours are 7 a.m. – 8 p.m. Central, Monday through Friday, as

well as 12-4 p.m. on Saturday and Sunday. The SOS Support team is available by phone

from 9 a.m. to 6 p.m. Central time, Monday through Friday.

SOS Inventory was designed to work with QuickBooks Online from the ground up. SOS

Inventory integrates tightly with QuickBooks Online to produce a world-class experience for

the user. The integration works via a two-way synchronization process in which data are

exchanged server to server. You can see more on the integration later in this user guide.

March 15, 2024

• Added three general sales setting descriptions—

Enable Line-Item Discounts on Sales

Forms

,

Show Cost/Markup on Sales Forms

, and

Markup on Actual Cost

—to Section

4.2.3.1, General.

• Added an invoice setting and description for

Use Shipping Cost from Shipment

, to

Section 4.2.3.4, Invoices.

• Updated Section 5.1.1.1, Item Field Descriptions, adding a definition for

Markup

and

revising the definition for

Sales Price

.

• Revised point 7 under Section 6.1.2.1, Rules for Working with Vendor-Item Catalog

Entries.

• Corrected points 5bi and 5bii under Option 2 of Section 6.2.8, Purchase Order

Prepayments. The correct value in the Qty column should be entered as

1

(a

positive

number), while the deposit amount entered in the Unit Price column should be entered

as a

negative

number.

• Revised Section 6.3.3, Landed Costs.

• Corrected Section 7.8, Invoices, so that the QuickBooks Online setting referenced in

points 1a and 1c is

Custom Transaction Numbers

.

• All of Chapter 9, Manufacturing (Production), has been rewritten to provide greater

detail and clarity.

• Updated Section 11.2, Custom Field Rules, to clarify the number of custom fields that

can sync with QuickBooks Online.

• Added a new subsection: Section 19.3.2.1, Updating Inventory Levels with Multiple

Shopify Locations.

• Added a new subsection: Section 19.3.5, Shopify Restrictions in Syncing Customer Data

to SOS Inventory.

• Corrected spelling of

ShipStation

in Section 19.8, ShipStation Integration.

• Under Section 25.3.5, Process Transaction Interaction, changed all notes that referred

to a

build

to state

process

.

• In Section 25.4.3, Work in Progress (WIP) Report, corrected the last sentence.

• Under Chapter 26, Frequently Asked Questions, revised the steps for the following FAQ:

When processing a sales order to shipment to invoice, the customer purchase order

number does not come across from SOS to QuickBooks Online. I am currently having to

enter it separately in QuickBooks Online. What might be causing that?

December 15, 2023

• Section 3.2, Inventory Tracking in QuickBooks Online, has been rewritten for clarity.

• Section 5.1.5, Investigating Inventory and Cost Basis Errors with Transaction History,

has been rewritten for clarity.

• Section 25.4.2, Inventory Value Report, has been rewritten to correct and clarify the

content.

October 6, 2023

• In Section 7.11 Price Tiers, deleted an incorrect phrase that said quantity buys could not

be edited using the Export Data/Import Data (bulk edit) features.

• Under Section 9.2.2 Bills of Materials (BOMs), corrected the breadcrumb navigation

listed for the Expanded BOM Report.

• Updated point 6c under Section 19.3.3, Shopify “Customer App” Cart Connection

Checklist (with SKU/SKU Matching to Support Updating Inventory Levels).

August 4, 2023

• Corrected point 1b under Section 3.1.2, Creating the Connection.

• Updated Section 3.1.3, First Sync, so that it specifies that the Retrieve from QuickBooks

function is the specific data utility to use if more than the most recent 1000

transactions need to be imported into SOS Inventory.

• Corrected Section 9.10.1, Contract Manufacturing Workflow, to state that an

expense

item should be created to represent the service fee of a contract manufacturer.

• Inserted new content, Chapter 16, Data Utilities.

• Added a note to Section 17.3, Importing Data, to clarify that the As Of date should not

be specified in SOS Inventory when a data import includes quantities and values as of

the current date.

May 30, 2023

• Corrected how to save categories in Section 5.1.3, Creating and Using Categories.

• Updated the list of QuickBooks data available under the Sync Menu in Section 17.6,

Other QuickBooks Online Data.

• Revised the information in Section 22.1, Setup Checklist for New QuickBooks Online

and SOS Accounts, and Section 22.2, Setup Checklist for Adding a New SOS Account to

an Existing QuickBooks Online Account.

March 7, 2023

• Revised how purchase orders in SOS Inventory are sent to QuickBooks in Section

17.1.1.1, SOS to QuickBooks Online.

• Corrected the hours during which email support is available where mentioned in the

user guide.

November 22, 2022

• Updated Section 1.1, History of SOS Inventory.

• Updated Section 3.1.1, Considerations Before Connecting, and Section 5.12, Kits (Item

Groups). Added information about the incompatibility of QuickBooks Online’s bundles

with SOS Inventory.

• Changed logo on user guide cover.

• Moved “What’s New: User Guide Notes”—formerly Chapter 26, it is now Chapter 2.

October 18, 2022

• Added a new subsection—5.1.2.1, Rules for Working with Vendor-Item Catalog Entries.

• Revised a sentence in Section 5.2.1.1, Purchase Order Transaction Fields. The Contract

Manufacturing field description was revised to clarify that it is used only as an internal

note.

• Revised a phrase in Section 5.6.5, Reorder Report. Changed the second sentence in the

first paragraph to state that the report shows all items in which the Available for Sale

quantity “is at or below” the reorder point. (Previously, the user guide said only

“below.”)

• Changed Chapter 26 title from “What’s New: Release Notes” to “What’s New: User

Guide Notes.” The content of the chapter has been revised, focusing on all changes

within the user guide rather than just those pertaining to software updates. (Revisions

to the software continue to be listed under the Help menu of SOS Inventory. Select

“What’s New” for release notes.)

Now that you know what plan you would like to use, you can start SOS Inventory. This should

be carefully thought out before beginning. You need to decide how you want to connect and

understand what happens when the connection is made. Towards the end of the guide is a

step-by-step checklist of what you would need to do to accomplish the setup of SOS Inventory

and the connection with QuickBooks Online. Please read this section first before using the

checklist.

SOS Inventory communicates with QuickBooks Online via a “connection,” which is simply an

authorization that you provide, giving permission for SOS to communicate with QuickBooks

Online on your behalf. If a connection is not active, the sync functions will not be available to

you.

Before you connect SOS Inventory to QuickBooks Online, you should understand possible

situations that may need to be corrected first.

• If you are connecting a brand-new account, you should be good to go for creating the

connection.

• If you are connecting SOS to an existing QuickBooks Online company account, ensure

that all data is ready to sync (charts of accounts, tax center, vendors, customers,

products and service). Note the following:

o Bundles. The bundle feature in QuickBooks Online is comparable to SOS

Inventory’s item groups (also known as kits), but bundles are not compatible

with SOS Inventory and will cause a sync error when QuickBooks attempts to

send bundled items or a transaction with bundled items to SOS Inventory.

If you have existing active bundles in QuickBooks Online, please either

inactivate the bundles or contact support@sosinventory.com to obtain

assistance in recreating these as items compatible with SOS Inventory.

o Inventory tracking. Another consideration is if you are tracking inventory in a

QuickBooks Online Plus account. For SOS Inventory to be your inventory

management solution, you MUST turn off QuickBooks Online’s Track Inventory

Quantity on Hand in your account settings.

In either case, please contact SOS Support to discuss at [email protected].

If you are moving from QuickBooks Desktop, QuickBooks Premier, or QuickBooks Enterprise to

a QuickBooks Online account, please contact QuickBooks Online Technical Support for more

details on that process.

When you follow this path knowing you will connect to SOS Inventory after the conversion into

QuickBooks Online, the recommended steps are:

1.

Create a QuickBooks Online account.

Make sure that Track Inventory Quantity on Hand

is turned OFF by going to the gear icon in the upper right, selecting Account & Settings,

selecting the Sales tab on the left, and the option is under Product and Services.

2.

Import your QuickBooks Online account into QuickBooks (QuickBooks Online Support

can answer questions).

When asked in a pop-up message during the import if you want

to track inventory, answer No. This will save you time later.

3.

Proceed to section 2.1.2, Creating the Connection.

You can create the connection in one of two methods:

1.

From SOS Inventory.

At https://www.sosinventory.com, select the Free Trial logo in

the upper right corner. Alternatively, you can go to the SOS Inventory login page,

https://live.sosinventory.com and click on I need an account. Either way, you just need

to provide your email address (which should also be an administrator in the

QuickBooks Online account), your display name, and select the plan level you want to

start. This will create your new SOS account.

a. For security, you should set your user profile password before continuing.

b. Now you need to connect to QuickBooks Online by clicking on the Settings

Menu (gear icon) and then QuickBooks Setup. Clicking on the Connect to

QuickBooks button will open a pop-up window that will walk you through

authorizing your QuickBooks Online Company to connect to SOS. Again, you

must be an administrator on QuickBooks Online to accomplish the connection.

SOS finds your QuickBooks Online Company by using your email address, so

make sure it matches in QuickBooks Online. See QuickBooks Setup later in this

guide for more on the automated sync.

2.

From QuickBooks Online.

In QuickBooks Online, go to the Apps option in the left-hand

menu. You should find SOS Inventory listed in the All Apps list. Click on Get App Now

to connect and answer the questions to complete the process as in the other method.

Using this method, it connects the products for you so you do not have to authorize the

connection separately.

No matter which method you use, as the person creating the connection you should now see an

icon in your My Apps list in QuickBooks Online for SOS inventory. Only the person making the

connection will have this option.

When you first make a connection from SOS to QuickBooks Online, SOS will begin

synchronizing your data by retrieving the relevant data in your QuickBooks Online account. All

customers, vendors, and items that are in QuickBooks Online will sync to SOS Inventory. But

only 1,000 most recent of

each

transaction type

will be synchronized to SOS.

This initial synchronization between QuickBooks Online and SOS Inventory typically takes

much longer than subsequent synchronizations. The first sync generally takes 15 minutes to an

hour to complete, depending on the volume of data in your account. You should not use SOS

Inventory while it is synchronizing. Wait until the process completes. When the sync

completes, you will get an email at the address used for your login letting you know.

If you need to sync more transactions than allowed for the initial sync, use the Retrieve from

QuickBooks data utility (Company Menu > Data Tools > Data Utilities) to obtain the additional

transactions. If you have defined Automated Order Processing (AOP) Rules (Company

Menu > Miscellaneous > AOP Rules) or have turned on Auto functions in the Sales Settings

(Settings > Sales Settings), the system will display a message stating that you must disable

these features before using the Retrieve from QuickBooks function. Once you are finished

retrieving transactions, you can enable those options again.

NOTE: If you need to sync additional transactions using Retrieve from QuickBooks, the

synchronization should be completed before executing an item conversion. An item

conversion is needed if inventory tracking was enabled in QuickBooks Online before you

connected to SOS. Please contact our Support desk if this condition exists. If sales orders,

invoices, and purchase orders are synced after an item conversion, transactions will include

the extension (deleted) at the end of each item listed on the transaction and reports in SOS will

not report historical data accurately for those items.

Click the Sync Menu in SOS to synchronize with QuickBooks Online at any time. Just click on

Sync Now to start the sync process. The Sync Menu can always be found on the top Task Bar

(See image in Graphic User Interface).

QuickBooks Online Plus includes an inventory tracking setting called Track Inventory Quantity

on Hand that allows you to keep track of your quantity on hand and cost of goods sold. If you

decide to use SOS Inventory because the inventory functionality in QuickBooks Online is

insufficient for your business needs, you do not want to manage inventory in both SOS and

QuickBooks Online. Use SOS Inventory only. For that reason, SOS customers should turn off

inventory tracking in QuickBooks Online.

If you are having duplicate cost of goods sold entries showing up in QuickBooks Online, the

cause is that inventory tracking has been enabled for some items in QuickBooks.

Consequently, both QuickBooks Online and SOS are posting to cost of goods sold—resulting in

duplicate entries.

If you have questions, please contact SOS Support to discuss at suppor[email protected].

Pictured to the right is SOS Inventory’s login page.

There are two methods of signing into SOS

Inventory. You can sign in using your SOS Inventory

username and password, or you can sign in using

your QuickBooks Online username and password. In

both cases, your SOS administrator must have set

up an SOS Inventory account for you.

The two methods in more detail are:

1.

Signing in with SOS Inventory.

To sign in

directly via SOS Inventory, go to https://www.sosinventory.com and click on the

Login to SOS link in the top right corner of the screen. Alternatively, you can go

directly to https://live.sosinventory.com . On that page, enter your SOS Inventory

username (email) and password. This might be different than your QuickBooks

username and password. If you don’t know your password, click the I forgot my

password link on the bottom left of the login page and follow the instructions.

2.

Signing in with Intuit (QuickBooks Online).

To sign in using your QuickBooks Online

credentials, go to https://www.sosinventory.com and click on the Login button in

the top right corner of the screen. Alternatively, you can go directly to

https://live.sosinventory.com. On that page, click the button labeled Intuit Sign in.

If you are already logged in to QuickBooks, SOS Inventory will log you in

automatically at that point. Otherwise, enter your Intuit username and password to

login. As a reminder, to use this option your email address must match exactly

within both SOS and QuickBooks Online.

In addition to the above sign-in methods, in QuickBooks Online, simply select Apps from the

left menu and go to the My Apps tab and select the SOS Inventory app. Note that QuickBooks

only makes this option available to one user per account, which is the person that actually

connected QuickBooks Online to SOS last.

To sign out of SOS Inventory, go to the User Menu (see next section) and click the Logout

option.

SOS Inventory’s GUI (see image) has been designed to be easy to use and visually coincide with

the look and feel of QuickBooks Online.

When you first login to SOS Inventory you will see the Home Screen. This is your starting point

to navigate through the system. It provides a message area where you’ll find messages from

the SOS team for you the user. Information provided will include important dates such as the

latest release, links to upcoming beta versions for you to test and get a preview of the

functionality, and reminders such as a link to the Support team.

The interface has three main areas of interest. Each area combines functionality to make SOS

Inventory easy to learn and use.

1. Task Bar

•

Company Menu.

This shows your company name and allows for company and

plan settings, data tools, and many functional lists for enhancing your SOS

operations and experience.

•

User Menu.

This shows your display name and provides user specific

functions such as settings and profile, task list, and an option for the user to

logout.

•

Notifications.

Allows a user to see if any notifications have been sent to him

and provides access to viewing past notifications or add new ones.

•

Search.

Allows for extended search of objects throughout SOS.

•

Add Menu.

One-stop menu to add any new transaction, items, etc.

•

Sync Menu.

Allows a user full control over synchronization between SOS and

QuickBooks Online.

•

Print.

Provides a facility to print the current display area.

•

Settings Menu.

One-stop menu for all settings used within SOS Inventory to

include transactional, operational, sync, portal, and integrations.

•

Help Menu.

Provides a wealth of resources for use SOS.

2. Operations Menu

This is the main list area for all existing transaction and reports for daily operations.

•

Dashboard.

Fast link to main information page.

•

Calendar.

Configurable calendar to see important information on

transactions such as overdue invoices and tasks.

•

Purchasing.

Contains vendors, purchase orders, item receipts, and returns to

vendors.

•

Production.

Contains builds, processes, jobs, and work orders.

•

Inventory.

Contains items, adjustments, transfers, serialized inventory, and

lots.

•

Sales.

Contains customers, estimates, sales orders, invoices, and sales

receipts.

•

Fulfillment.

Contains pick tickets and shipments.

•

More Transactions.

Contains RMAs, returns, rentals, and rental returns.

•

Reports.

One-stop page for all reports available in SOS Inventory.

•

Quick Links.

Configurable shortcut list for common actions.

3. Page Display Area

This is the main section of the screen for displaying pages throughout the software.

This area can be increased by clicking on the double left arrow icon at the bottom of the

Operations Menu, which reduces the menu to just icons. Click the double right arrow

icon to expand the menu to show icons with their titles.

The menus and operations available are dependent on the user’s privileges. These areas will be

discussed in more detail as you get further into the user’s guide.

To access sub-menus, simply click on one of the main menus in the Operations Menu or

buttons on the Task Bar.

This guide refers to actions using a tiered structure in a drill-down usage. For example,

Company Menu > Company Settings tells you to go to the Company Menu and choose the

Company Settings option under the Admin section.

The heart of SOS Inventory is its lists, e.g., Items list, Purchase Orders list, Sales Orders list,

etc. The lists provide a summary view of the data in SOS Inventory and allow the user to drill

down for further information if desired. Let’s look at the anatomy of a list page.

In the blue bar at the top of the list, the Display Message shows you a summary of the current

settings for the page, such as “Showing 25 unarchived items.” This message is set in the

Change Filter.

The Page Navigation icons are located at the top and bottom of a list page. This feature is

shown as chevrons (« and ») with numbers between them. Click on a number to go to that

page of the list or click on either of the chevrons to go to the first or last page. The number of

items on a page is set in the Change Filter.

The Actions Menu provides options you can apply to a specific entry on a list. To see the actions

available for a row, click on the down arrow next to Edit. The options vary, depending upon the

particular list. The default action on most lists is Edit, as it is the most commonly used action

for existing entries.

The Batch Actions dropdown list allows you to select a common action and apply it to multiple

rows of entries. Click on the box on the left of each row you want the batch actions to affect.

Clicking the box on the column title row selects every line on that displayed page.

The Change Filter button allows you to select the specific type of information you want from

the list.

Quick Search is an intelligent search limited to data within a list, enabling you find one or more

items which meet the search string. Not all columns are searched. Contact Support if you have

a question about this function.

The Add New button allows you to create a new entry of the same type as those displayed on

the list you are currently viewing.

This button is found on almost all lists in SOS Inventory. In this regard, the list page Add New

feature differs from the Task Bar’s Add (+) Menu. The Add Menu is a “quick add” feature that

allows you to bypass navigating through a list page to create a new page of data—but it is

limited to adding new items, customers, vendors, and transactions only.

The gear icon at top of the list, the Column Chooser, allows you to choose columns of

information to display that are appropriate to the type of list. When the Column Chooser icon

is selected, a pop-up window with all column options for that list appears on your screen.

Simply check or uncheck the box next to the column name to display or hide that column.

When you have finished making your column choices, go to the bottom of the pop-up window

and select Apply.

The Excel Export icon at the top of the list lets you save your currently viewed data as a

spreadsheet. This affects only the page of data you are displaying and not the entire list across

multiple pages.

Stars is a feature set in the Company Settings. You can use it as a reminder or in a stoplight

fashion to show importance of that row in the list.

For every type of object in SOS (item, transaction, etc.) there is an edit page. It is accessed via

the Edit action, the default action on most lists. In the top left corner of every edit page are the

navigation buttons for that page.

The gray Back Arrow button takes you to the list from which you entered the edit mode. If you

use the browser’s back button instead of the gray back arrow, the browser will take you to the

previous operations page before your current list. The Print button gives you a screen print of

the page you are on. The Save and Close button completes the edit and returns you to the list.

Some pages have a More button which provides additional options after the save is completed.

Each user has settings and a unique user profile which they should establish for themselves

after they login for the first time. These can be found under the User Menu (your display name)

on the Task Bar.

The User Profile contains a display name, email address (used as username for logging in),

password, security question and answer, as well as, listing your mobile carrier and mobile

number for text-based notifications which will be discussed in depth later in this guide. To edit

any of this information, go to the Task Bar and select User Menu > User Profile, make your

changes, and click Save in the lower right corner.

NOTE: If you are an administrator, be sure to use the User Profile function as described above to

change your email address, not the User Administration function under the Company Menu.

Users in SOS Inventory do not always have the same time zone or use the same date format for

transactions. User Settings allows you to change these to match your area. All users must set

their time zone setting for transactions to be recorded correctly. User Settings also allows you

to choose how you receive notifications. You can edit this information by going to User Menu >

User Settings, making your changes, and clicking Save in the lower right corner.

Users can set tasks for themselves or others in SOS with due dates so they can be tracked on the

calendar. To add tasks, go to User Menu > Tasks. You can click Add New on the right to add a

new task. Provide a title for the task (must be unique), a description to explain the task if

needed, assign it to yourself or another user in SOS, and set a complete by date. Once the task is

finished, you can either (1) click the Completed option on the task’s edit page, or (2) select

Mark as Complete from the Actions Menu on the Task list.

SOS and QuickBooks Online are separate online products, and thus separate websites. SOS does

not add extra menus to QuickBooks Online. You use both products and they simply exchange

data behind the scenes. One of the most common questions we get is how the user should

switch back and forth between the two products. These are the common approaches:

•

No switching.

Many users simply have no need to switch between SOS and QuickBooks

Online on a regular basis. For example, when running financial reports, you can open

QuickBooks Online and do what is needed. When working with inventory, you can open

SOS and do what is needed. The data will still synchronize per your settings.

You do not

need to have both programs open for them to exchange data, and you do not need to be

logged into them either.

•

Multiple tabs.

Virtually all web browsers today offer the ability to create multiple tabs,

where each tab can view a different website. Our favorite method of switching from SOS

to QuickBooks Online and vice versa (and the method we use here at SOS), is to open

one tab to SOS and one tab to QuickBooks Online. Then switching between the two

programs requires only one simple, fast click.

If you have multiple SOS Inventory company accounts and a user accesses those accounts with

the same email address, that person can switch between accounts by going to Company Menu

> Change Companies. The user may also designate the company that serves as the default

when logging in to SOS Inventory.